Just Turbines

#221

Registered

Agreed. Safety wiring is the last art form left to the mechanic. All the old tricks of polishing and lapping and hand fitment are gone (most likely a good thing) since machining centers can now hold such fantastic tolerances and produce such smooth surface finishes. We're left with safety wiring. Enjoy.

You electrical guys face the same fate. Can bus technology is rapidly erasing the art of constructing a great wire loom. Now a single wire can do the same job that used to require dozens.

You fiberglass guys and painters are probably still OK for a little while!

A great thread. I find this fascinating. Thank you.

Dan

You electrical guys face the same fate. Can bus technology is rapidly erasing the art of constructing a great wire loom. Now a single wire can do the same job that used to require dozens.

You fiberglass guys and painters are probably still OK for a little while!

A great thread. I find this fascinating. Thank you.

Dan

#222

Registered

Thread Starter

I agree!!!

While we are killing some time waiting for the puller to remove the diffuser housing.

Lets take a look at the braking system.

For those that may not know a T53 is free wheeling turbine which means it has too completely separate systems as i have shown.

The n2 which is basically the propeller and the n1 the engine.

the brake is used to stop n2 at ground idle to shift a crash box. A piston engine would have to be shut off to do this

the turbine can actually be stopped for a minimal amount of time to allow a shift.

While we are killing some time waiting for the puller to remove the diffuser housing.

Lets take a look at the braking system.

For those that may not know a T53 is free wheeling turbine which means it has too completely separate systems as i have shown.

The n2 which is basically the propeller and the n1 the engine.

the brake is used to stop n2 at ground idle to shift a crash box. A piston engine would have to be shut off to do this

the turbine can actually be stopped for a minimal amount of time to allow a shift.

#223

Registered

Thread Starter

#224

Registered

Thread Starter

This whole setup you can now purchase from SCS.

Basically a zero drag SCS crash box with a turbine "bellhousing" and a modified input shaft.

Basically a zero drag SCS crash box with a turbine "bellhousing" and a modified input shaft.

#225

Registered

Ok here we go again!

I would like to show the general audience of Offshore Only how someone takes a perfectly fine running 46 Skater sporting

Lycoming T53 Turbines apart for general maintenance and inspection.

Its been 5 years lets Rock!

Please understand that just because you read it on the internet it must be true!

Nothing in the following thread should be tried at your local airport or at home!

Stay tuned as we move forward!!

Here is the what it looks like

[IMG] [/IMG]

[/IMG]

I would like to show the general audience of Offshore Only how someone takes a perfectly fine running 46 Skater sporting

Lycoming T53 Turbines apart for general maintenance and inspection.

Its been 5 years lets Rock!

Please understand that just because you read it on the internet it must be true!

Nothing in the following thread should be tried at your local airport or at home!

Stay tuned as we move forward!!

Here is the what it looks like

[IMG]

[/IMG]

[/IMG]

#226

Registered

Thread Starter

#227

Registered

Thread Starter

#228

Registered

Thread Starter

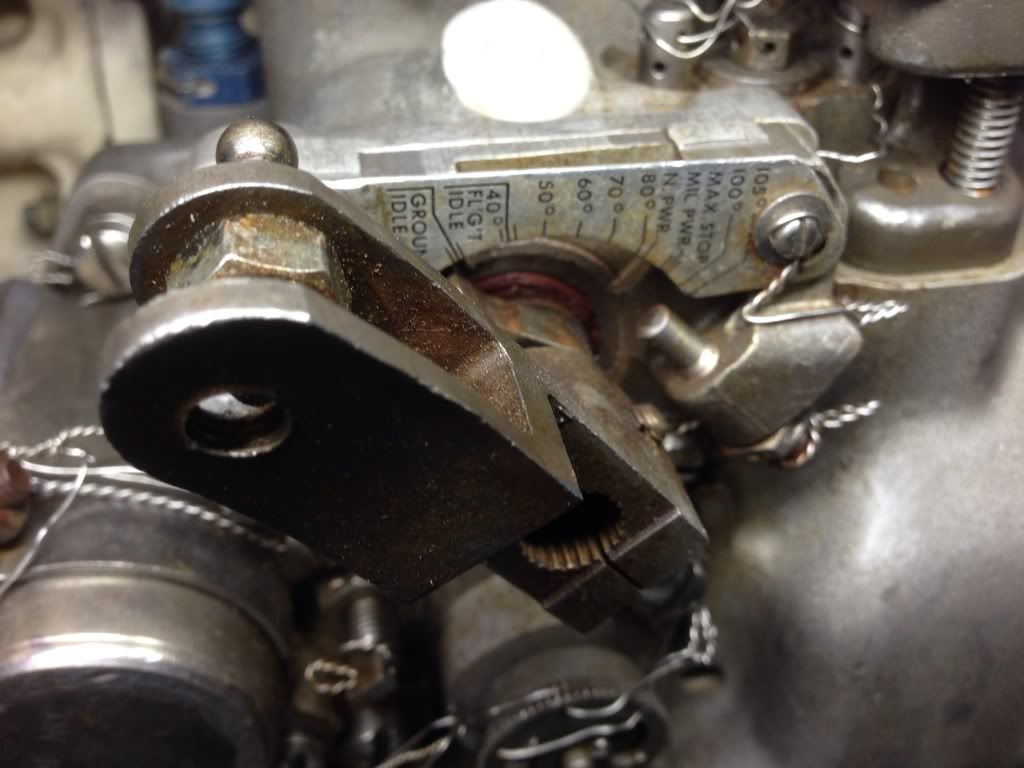

The n2 control quadrant is wire tied wide open...This is the governor of the n2 system..

in a helicopter there is a droop compensator which moves this with a linear actuator if the pilot sees the rotor speed

drooping it will move this quadrant this is item 25 on the schematic.

in a helicopter there is a droop compensator which moves this with a linear actuator if the pilot sees the rotor speed

drooping it will move this quadrant this is item 25 on the schematic.

Last edited by KNOT-RIGHT; 12-06-2013 at 04:40 PM.

#229

Registered

Thread Starter

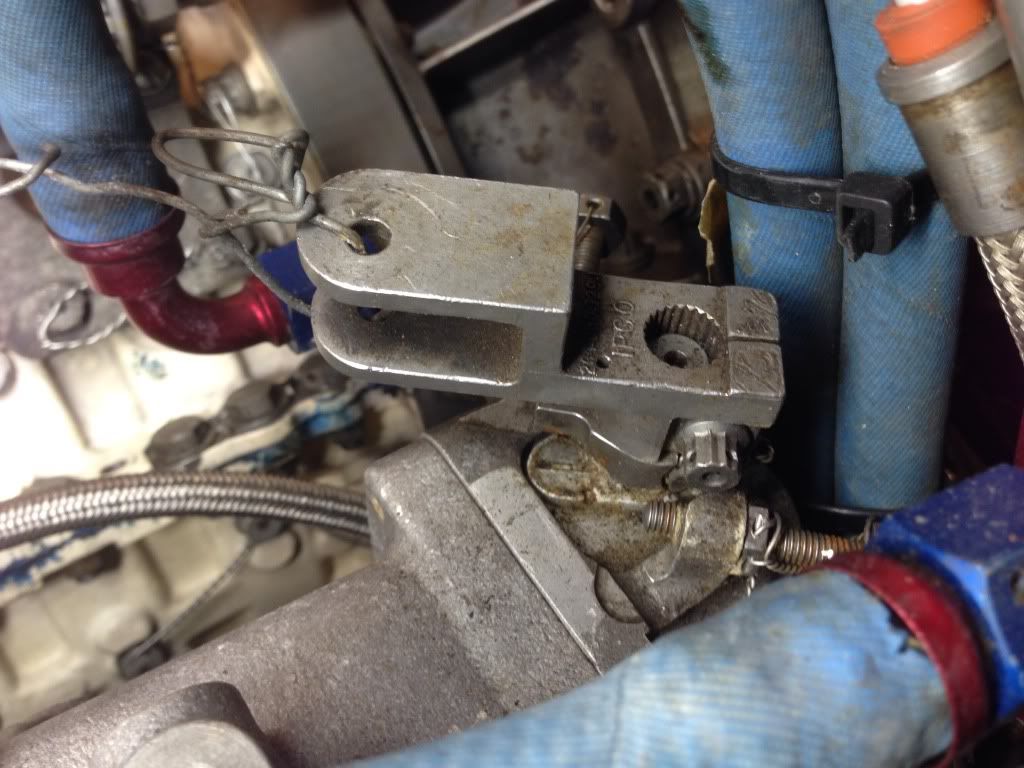

Please be advise that if you tweak these screws you may lead to broken number six

drives shafts propellers or even exceeding the limits of your t53. You have been warned!

these are items N and O in schematic. Look closely at it one will offset the other its on a ramp internally.

Trimmer screws...One controls a increase in engine torque and one controls the idle percentage of

N1. A quarter of a turn increases torque 12%

drives shafts propellers or even exceeding the limits of your t53. You have been warned!

these are items N and O in schematic. Look closely at it one will offset the other its on a ramp internally.

Trimmer screws...One controls a increase in engine torque and one controls the idle percentage of

N1. A quarter of a turn increases torque 12%

#230

Registered

Thread Starter

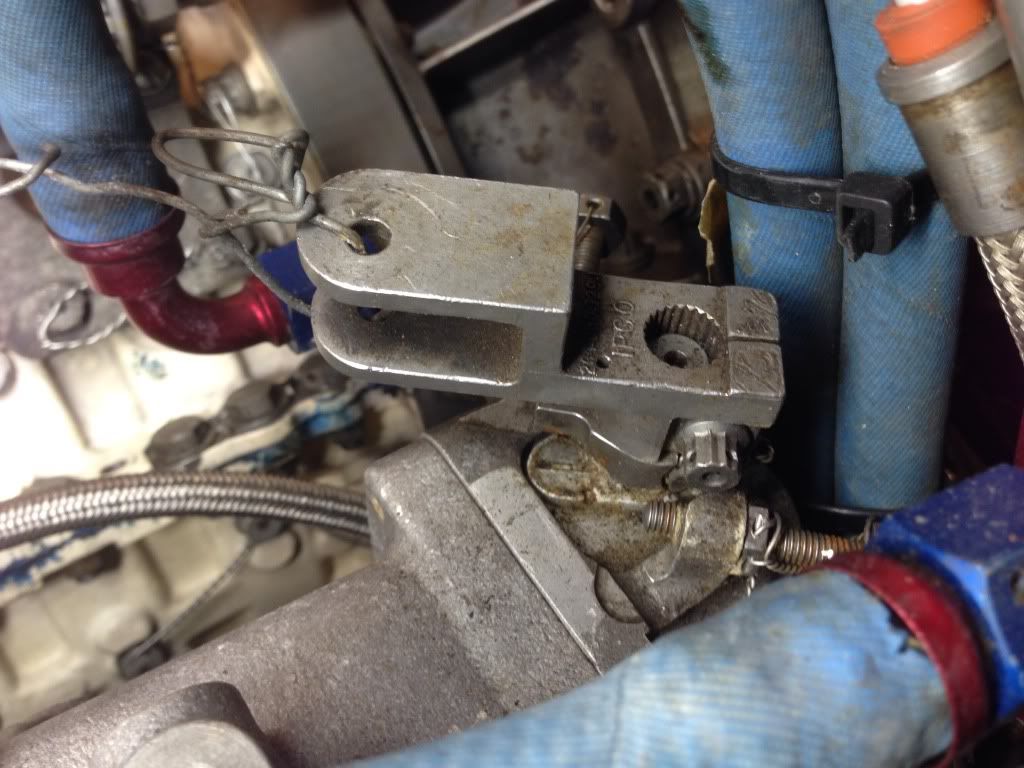

Now that you cannot keep mercury sixes on the boat because you should have used Arnesons or Bpms in the first place.

If you would like to try to blowup these Arnesons or bpms

Try turning this screw its item 10 on the schematic it turns the fuel pressure and flow way up be careful because it does not adjust

any other wonderful little things that fuel control is doing.

here is what the destroyer knob looks like. Again you have been warned it shows no Mercy!

If you would like to try to blowup these Arnesons or bpms

Try turning this screw its item 10 on the schematic it turns the fuel pressure and flow way up be careful because it does not adjust

any other wonderful little things that fuel control is doing.

here is what the destroyer knob looks like. Again you have been warned it shows no Mercy!

Last edited by KNOT-RIGHT; 12-06-2013 at 05:03 PM.