Enginetech Stellite Exhaust Valves?

#1

Registered

Thread Starter

Join Date: May 2014

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

Only found 2 threads that have any mention of stellite coated valves and one of those two references the other thread...

Thread #1

Thread #2 relevant post

Reading through thread #1, I don't see a consensus that stellite is the next best (vs inconel) as claimed in thread #2 nor were they used in some big block GM truck engines. They did use different valves but they appear to have been inconel.

Just reading through general valve selection information on the web, the consensus seems to be that stellite coated is the next best for exhaust valves for those that can't afford or justify inconel. But, that also implies that the comparison is between valves from the same manufacturer. It does not consider, say, a stelllite coated valve from a good manufacturer vs a stainless from one of the best manufacturers.

Enginetech is the only "manufacturer" I can find that even have stellite coated valves for a 350 vortec. From what I found, enginetech is the walmart of the rebuilder industry. They don't actually make anything but they move such volume that they have the best prices on rebadged parts. But, you can't request and you never really know what manufacturer you're getting in the enginetech box. In this case, I'm thinking they may be the Sealed Power valves because they have the same part number style. Usually, in my experience, when a part is made by someone else for another company, the part number is identical or just slightly changed. Sealed Power makes a stellite coated valve but not for the vortec. I'm thinking they were maybe discontinued because rock auto used to carry them but now they're out of stock and I can only find them on fleabay.

Even if they're not Sealed Power they should be a decent brand. From what I've read, Enginetech carries middle of the road quality. They're just rebadged. Not the best but not junk either.

So, would it be better to go with a stellite coated, 23-8N stainless Enginetech (Sealed Power?) exhaust valve or a stainless Ferrea 5000 or 6000 series?

Or, just stick with my stockers and get a nice 30 deg back cut on em and use the savings to upgrade to forged pistons for a 383 with 5.7 rods?

Thread #1

Thread #2 relevant post

Reading through thread #1, I don't see a consensus that stellite is the next best (vs inconel) as claimed in thread #2 nor were they used in some big block GM truck engines. They did use different valves but they appear to have been inconel.

Just reading through general valve selection information on the web, the consensus seems to be that stellite coated is the next best for exhaust valves for those that can't afford or justify inconel. But, that also implies that the comparison is between valves from the same manufacturer. It does not consider, say, a stelllite coated valve from a good manufacturer vs a stainless from one of the best manufacturers.

Enginetech is the only "manufacturer" I can find that even have stellite coated valves for a 350 vortec. From what I found, enginetech is the walmart of the rebuilder industry. They don't actually make anything but they move such volume that they have the best prices on rebadged parts. But, you can't request and you never really know what manufacturer you're getting in the enginetech box. In this case, I'm thinking they may be the Sealed Power valves because they have the same part number style. Usually, in my experience, when a part is made by someone else for another company, the part number is identical or just slightly changed. Sealed Power makes a stellite coated valve but not for the vortec. I'm thinking they were maybe discontinued because rock auto used to carry them but now they're out of stock and I can only find them on fleabay.

Even if they're not Sealed Power they should be a decent brand. From what I've read, Enginetech carries middle of the road quality. They're just rebadged. Not the best but not junk either.

So, would it be better to go with a stellite coated, 23-8N stainless Enginetech (Sealed Power?) exhaust valve or a stainless Ferrea 5000 or 6000 series?

Or, just stick with my stockers and get a nice 30 deg back cut on em and use the savings to upgrade to forged pistons for a 383 with 5.7 rods?

Last edited by Gannz; 08-29-2016 at 02:28 PM.

#2

Registered

I followed your other thread. In your situation I'd go the ferrea 6000. Could probably get away with 5000 series considered your driving characteristics but I'd really make the best effort to get the 6000's. the other thing I was gonna mention was your exhaust seats. I don't recall whether or not you mentioned those or not but... Even though you may run lower rpm from point a to b there is still a big load on your engine which creates the heat. Here's my 02 cents. Do the best you can now with the funds you currently on your heads. I've cheated with for chits and grin builds with gm 3/8 rods and cast cranks on 454 builds dyno'd just under 500hp years ago and beat the livin dog poop out of them and never ever had lick of problems. however I did put the best of the best in the heads/valves do to the heat I knew they'd sustain. Did not want a valve to potentially destroy an engine.

Are the valves currently in the engine stock gm exhaust valves? Other option however remember potential additional power. Stroker etc. More power = more heat.

The other valves from enginetech I am afraid would be to much of a gamble. Seriously.. I do know however there is a ton of brother sister companies out there these days or under the same umbrella so to speak but I'd imagine enginetech send what they have at the present time. I would have to imagine some come from here and others there. Where ever they can get the best bulk price. I've heard nothing bad about the company however I've heard or read nothing regarding their valves in marine engines. Remember also many off brand over seas companies know the game. Meaning part numbers etc. dont fall for that. Sometimes they will even be the same. Lawsuits and litigations going on all the time however dealing overseas is extremely difficult and costly. It's buyer beware and buyer be smart. We run into this all the time with golf clubs.

If you do do a stroker at some point be sure and pm me I will give you a good cam grind that works awesome in a 383.

Are the valves currently in the engine stock gm exhaust valves? Other option however remember potential additional power. Stroker etc. More power = more heat.

The other valves from enginetech I am afraid would be to much of a gamble. Seriously.. I do know however there is a ton of brother sister companies out there these days or under the same umbrella so to speak but I'd imagine enginetech send what they have at the present time. I would have to imagine some come from here and others there. Where ever they can get the best bulk price. I've heard nothing bad about the company however I've heard or read nothing regarding their valves in marine engines. Remember also many off brand over seas companies know the game. Meaning part numbers etc. dont fall for that. Sometimes they will even be the same. Lawsuits and litigations going on all the time however dealing overseas is extremely difficult and costly. It's buyer beware and buyer be smart. We run into this all the time with golf clubs.

If you do do a stroker at some point be sure and pm me I will give you a good cam grind that works awesome in a 383.

#3

Registered

Thread Starter

Join Date: May 2014

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

All good points and advise. Thanks. I'll go with the Ferrea 6000.

Which ones? Stock are 1.5 head, 11/32 stem, and 4.91 length.

Any benefit to running 1.55 or 1.6 heads? Extra machine work involved for them to fit?

Any need or benefit in using 4.96 or 5.01 length? I have the following howards cams springs with stock 1.5 stamped rockers, stock pushrods, and an LT4 hotcam...

Seat Pressure: 115 @ 1.700"

Open Pressure: 300 @ 1.250"

Valve Spring Rate: 411

Maximum Suggested Lift: .500"

Coil Bind: 1.160"

If valve length depends on rocker selection... If I can find a good deal on 1.5 rollers I may upgrade but only because the stock stamped are known to not be true to the ratio. I really don't see a need to go with 1.6 rollers and if I do it would be on the intake only. I've read 1.6 actually hurts the exhaust flow on vortec heads. And for 1.6 I'll probably have to get different springs, machine the seats, different push rods, widen the push rod guides, etc. Not worth it IMO for maybe a few more HP.

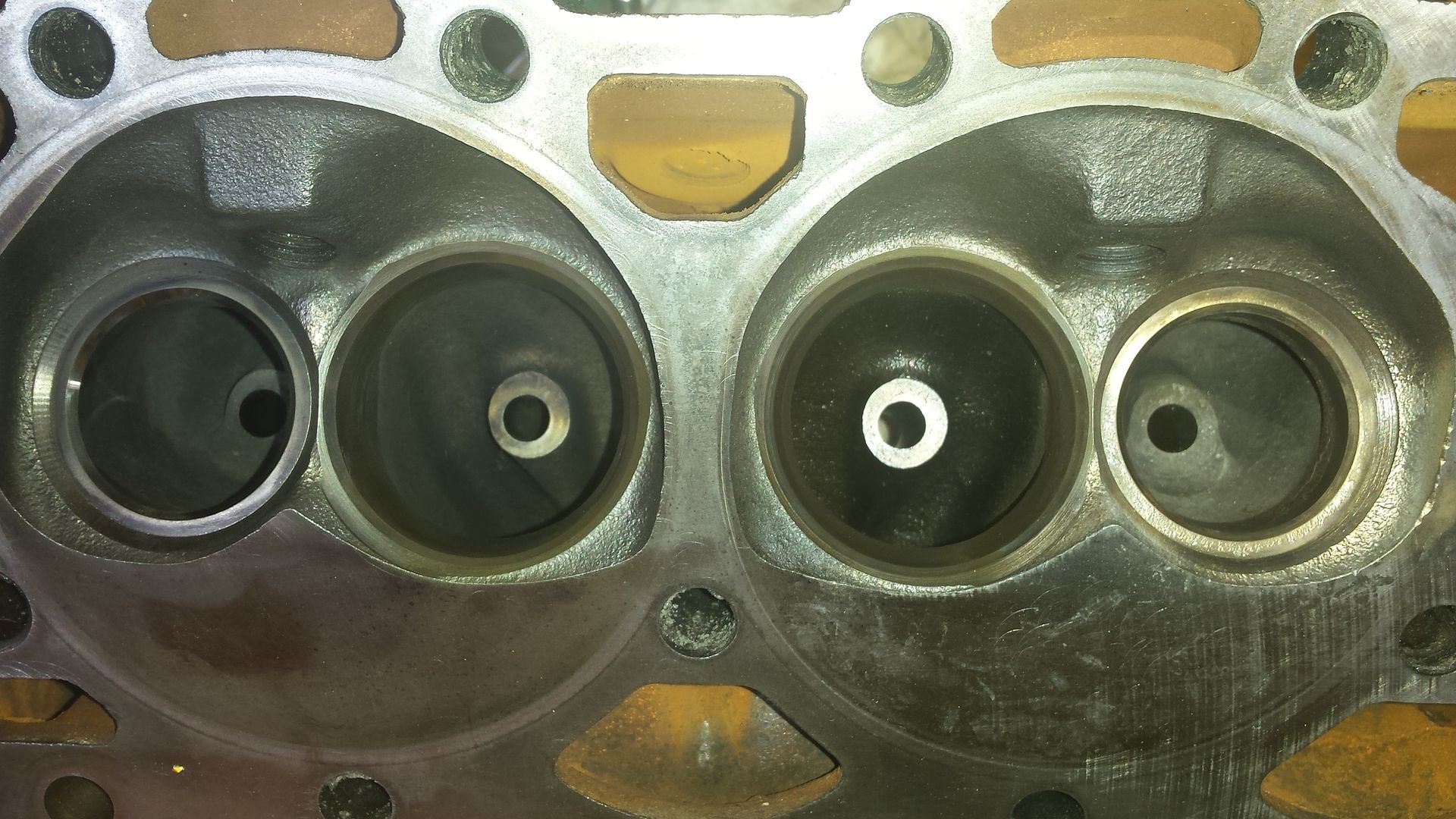

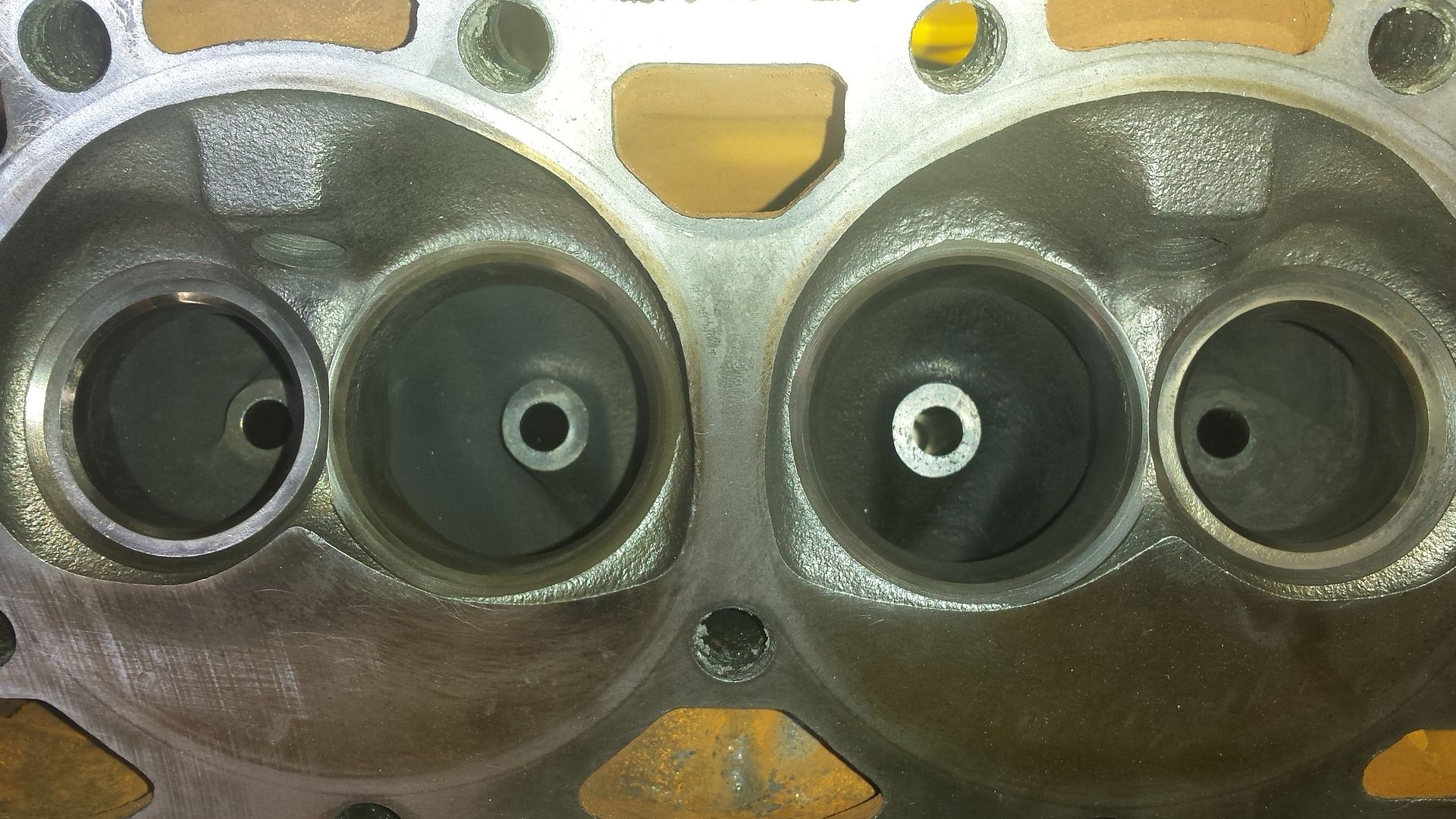

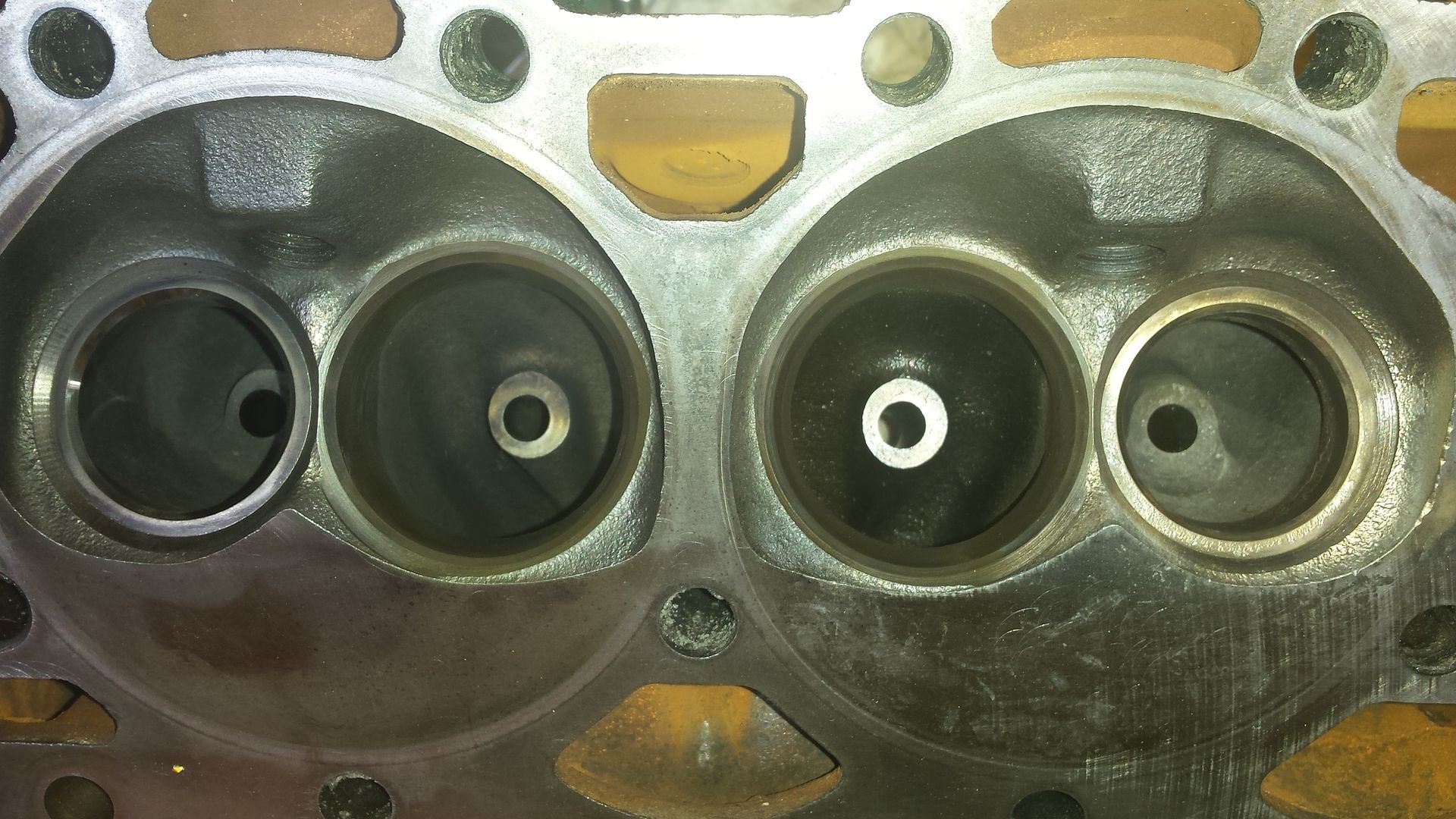

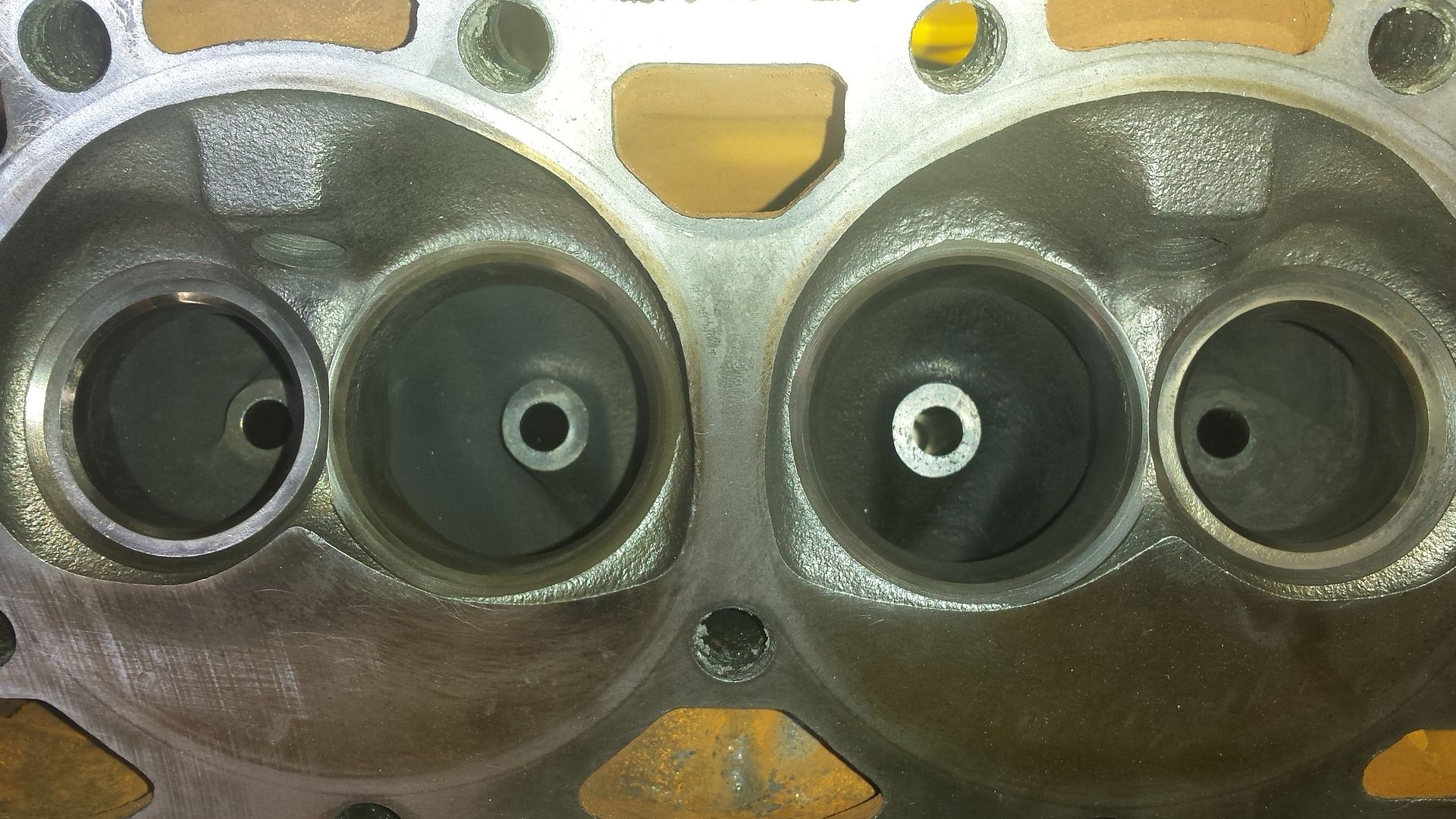

I have 906 heads which I understand some of them have iconel exhaust seats. Not sure what they look like but it does look like there's an insert in my exhaust seats.

They've been cleaned up with a brass wire brush on the Dremel. There is some roughness on the middle cut. It's the worst on the one that exploded. It's not really any thicker or "worse" it just covers more of the seat on that cut. I was just going to grind it off with the Dremel. LOL. Just kidding. But I was thinking it would smooth out when I lapped them. Get a fresh 3 angle grind done by the shop or do they look okay?

Yes, all valves are stock right now. Okay to keep and reuse the stock intake valves? They're in good shape and the stems have no wear. I was going to have a nice wide 30 degree back cut put on them to improve flow. Super Chevy did some testing and found that simple tweak improved flow by 3-8%. Not huge but for $20 it's a good bang for the buck.

Which ones? Stock are 1.5 head, 11/32 stem, and 4.91 length.

Any benefit to running 1.55 or 1.6 heads? Extra machine work involved for them to fit?

Any need or benefit in using 4.96 or 5.01 length? I have the following howards cams springs with stock 1.5 stamped rockers, stock pushrods, and an LT4 hotcam...

Seat Pressure: 115 @ 1.700"

Open Pressure: 300 @ 1.250"

Valve Spring Rate: 411

Maximum Suggested Lift: .500"

Coil Bind: 1.160"

If valve length depends on rocker selection... If I can find a good deal on 1.5 rollers I may upgrade but only because the stock stamped are known to not be true to the ratio. I really don't see a need to go with 1.6 rollers and if I do it would be on the intake only. I've read 1.6 actually hurts the exhaust flow on vortec heads. And for 1.6 I'll probably have to get different springs, machine the seats, different push rods, widen the push rod guides, etc. Not worth it IMO for maybe a few more HP.

I have 906 heads which I understand some of them have iconel exhaust seats. Not sure what they look like but it does look like there's an insert in my exhaust seats.

They've been cleaned up with a brass wire brush on the Dremel. There is some roughness on the middle cut. It's the worst on the one that exploded. It's not really any thicker or "worse" it just covers more of the seat on that cut. I was just going to grind it off with the Dremel. LOL. Just kidding. But I was thinking it would smooth out when I lapped them. Get a fresh 3 angle grind done by the shop or do they look okay?

Yes, all valves are stock right now. Okay to keep and reuse the stock intake valves? They're in good shape and the stems have no wear. I was going to have a nice wide 30 degree back cut put on them to improve flow. Super Chevy did some testing and found that simple tweak improved flow by 3-8%. Not huge but for $20 it's a good bang for the buck.

#5

Changing the valve length will change the amount of valve spring shims needed to get the installed height right. The stock length should be what you need.

For your application, I don't think you need to go bigger on the exhaust valve. Some do on the intake, but it needs to blended into the bowl or flow will be worse.

A 3 angle valve job won't hurt along with a 30 degree back cut on the intake valve. I would have the heads checked for any cracks at the machine shop, especially around the exhaust seat.

Any time valve train is changed, pushrod length should be checked.

The retainer (depending on the one you're using) gets very close to the valve seal at around .48 inches of lift. Since you are at .492 inches, you should check this. I think you want .020 inches of clearances or so at max lift.

You are correct about the issues of going to 1.6 rockers, however optimum flow on a vortec head is around .52 inches which is where the hot cam is with the 1.6 rockers, and is also what was used in the LT4.

For your application, I don't think you need to go bigger on the exhaust valve. Some do on the intake, but it needs to blended into the bowl or flow will be worse.

A 3 angle valve job won't hurt along with a 30 degree back cut on the intake valve. I would have the heads checked for any cracks at the machine shop, especially around the exhaust seat.

Any time valve train is changed, pushrod length should be checked.

The retainer (depending on the one you're using) gets very close to the valve seal at around .48 inches of lift. Since you are at .492 inches, you should check this. I think you want .020 inches of clearances or so at max lift.

You are correct about the issues of going to 1.6 rockers, however optimum flow on a vortec head is around .52 inches which is where the hot cam is with the 1.6 rockers, and is also what was used in the LT4.

#6

Registered

Thread Starter

Join Date: May 2014

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

Just for anyone else who might read this thread... It is 40% off the Ferrea website prices but they're priced much higher than other vendors and they want $20-30 for shipping. It is still cheaper and very cool of them to have the discount but it works out to about 10% lower than what everyone else sells them for.

#7

Registered

So you are not military ?

#8

Registered

Thread Starter

Join Date: May 2014

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

Changing the valve length will change the amount of valve spring shims needed to get the installed height right. The stock length should be what you need.

For your application, I don't think you need to go bigger on the exhaust valve. Some do on the intake, but it needs to blended into the bowl or flow will be worse.

A 3 angle valve job won't hurt along with a 30 degree back cut on the intake valve. I would have the heads checked for any cracks at the machine shop, especially around the exhaust seat.

Any time valve train is changed, pushrod length should be checked.

The retainer (depending on the one you're using) gets very close to the valve seal at around .48 inches of lift. Since you are at .492 inches, you should check this. I think you want .020 inches of clearances or so at max lift.

You are correct about the issues of going to 1.6 rockers, however optimum flow on a vortec head is around .52 inches which is where the hot cam is with the 1.6 rockers, and is also what was used in the LT4.

For your application, I don't think you need to go bigger on the exhaust valve. Some do on the intake, but it needs to blended into the bowl or flow will be worse.

A 3 angle valve job won't hurt along with a 30 degree back cut on the intake valve. I would have the heads checked for any cracks at the machine shop, especially around the exhaust seat.

Any time valve train is changed, pushrod length should be checked.

The retainer (depending on the one you're using) gets very close to the valve seal at around .48 inches of lift. Since you are at .492 inches, you should check this. I think you want .020 inches of clearances or so at max lift.

You are correct about the issues of going to 1.6 rockers, however optimum flow on a vortec head is around .52 inches which is where the hot cam is with the 1.6 rockers, and is also what was used in the LT4.

I did the ghetto grind on the retainers when I built everything about 2 years ago. I have .60 to .65 inches of clearance between the retainer and seal so good to go there.

I am confused on how that works when going to 1.6 rockers though. Do I need to have stronger or taller springs or does it just depend on that clearance between the retainer and seal? 1.6 rockers will get me to .525 lift and @ .60 I still have enough clearance.

Last edited by Gannz; 08-30-2016 at 02:16 PM.

#9

Registered

Thread Starter

Join Date: May 2014

Posts: 92

Likes: 0

Received 0 Likes

on

0 Posts

No, not military and I'm not going to abuse a military discount. Was joking that I'd get my brother in law, who is retired military, to get them for me for a Christmas present. He always gets me crap I don't use so that would be a nice change. LOL

Unless your asking because you don't know what to get me for Christmas?

Unless your asking because you don't know what to get me for Christmas?

Last edited by Gannz; 08-30-2016 at 02:18 PM.

#10

Thanks. I'll go with the stock specs then and I'll check the pushrods once everything is put together. I understand that's the last thing that gets checked and changed if necessary so that's a ways away.

I did the ghetto grind on the retainers when I built everything about 2 years ago. I have .60 to .65 inches of clearance between the retainer and seal so good to go there.

I am confused on how that works when going to 1.6 rockers though. Do I need to have stronger or taller springs or does it just depend on that clearance between the retainer and seal? 1.6 rockers will get me to .525 lift and @ .60 I still have enough clearance.

I did the ghetto grind on the retainers when I built everything about 2 years ago. I have .60 to .65 inches of clearance between the retainer and seal so good to go there.

I am confused on how that works when going to 1.6 rockers though. Do I need to have stronger or taller springs or does it just depend on that clearance between the retainer and seal? 1.6 rockers will get me to .525 lift and @ .60 I still have enough clearance.

With more lift and more rpms, the press in studs become a weak point. Screw in studs are the way to go to avoid that issue. Collared ones will require machining the bosses down, but you can get collarless screw in replacements that don't require milling the bosses. Only tapping the existing rocker stud hole. Summit sells a guide that makes this easy. Also, the pushrod hole in the head has to be drilled out because the pushrod will hit with a 1.6 rocker.