Finally Started the LS Swap

#21

Registered

Thread Starter

Corey331 and mgdoors have very good threads on there ls installs and the issues/fixes they ran into with builds and rigging. I suggest you deep dive.

as far as fuel pumps and etc for any decent ho engine, lots of threads on normal engines. Ext coast guard approved pumps, how to rig snd make return, etc

i may have spelled those members name wrong but will be close.

as far as fuel pumps and etc for any decent ho engine, lots of threads on normal engines. Ext coast guard approved pumps, how to rig snd make return, etc

i may have spelled those members name wrong but will be close.

I have read through there threads many times, they are very informative. I got a good deal on an AEM 50-1005 pump off the facebook marketplace that im going to at least use to get the boat running. Eventually I will get a USCG approved fuel pump and keep the AEM one on the boat as a spare.

#22

Registered

Thread Starter

Iím on the downhill side of this type of swap too.

did you upgrade the main and connecting rod bearings? The engine will be higher revving rpm for Longer than a car. Look at kings xp (what I did or clevite h)

new pistons and rings

Deleted dod and put in ls7 style lifters

trunnion upgrade

I had to get a flywheel plate and a big merc coupler and bell housing.

did the external fuel pump (aem from summit) and dbc throttle body.

raw water pump is tricky I did the marine engine depot thing with a crank mounted Johnson pump with the mounting bracket and bushing.

running closed cooling like crusader set up their 6.0

Guessing you know Volvo has adopted these now.

I got a lot Of inspiration from ilmor and crusader but plenty others like Volvo running these now.. irocx said he was fixing his raw water pump with bracket.

did you upgrade the main and connecting rod bearings? The engine will be higher revving rpm for Longer than a car. Look at kings xp (what I did or clevite h)

new pistons and rings

Deleted dod and put in ls7 style lifters

trunnion upgrade

I had to get a flywheel plate and a big merc coupler and bell housing.

did the external fuel pump (aem from summit) and dbc throttle body.

raw water pump is tricky I did the marine engine depot thing with a crank mounted Johnson pump with the mounting bracket and bushing.

running closed cooling like crusader set up their 6.0

Guessing you know Volvo has adopted these now.

I got a lot Of inspiration from ilmor and crusader but plenty others like Volvo running these now.. irocx said he was fixing his raw water pump with bracket.

I will be use the water pump in the apha 1 for cooling, but thats all I really have figured out at this point. I have a bunch of ideas, just need my manifolds to get here so I can figure out plumbing.

#23

well 1 season should be fine but that will put more wear than expected on it from what I’m told (it does make sense).

Curious how roller rockers do for you. I assume you mean roller tip rockers and not a trunnion upgrade?

Which manifolds did you order? I don’t recall seeing that. Also will you need spacers? I ordered these

https://www.hardin-marine.com/p-1045...-53-60-62.aspx

Yah that alpha will make things a little easier from raw water pickup point of view.

i like that that my manifolds are aluminum. I hate that I’ll have to mill my own spacers out of aluminum but such is life.

I ended up using ict and michiganmotorz for coil extenders and relocation brackets for my coils to go on transom.

im going bravo 3 and I ended up needing the shift bracket thing 807962a15

dont overlook your cooling system. I have a crusader RA0147048a for my heat exchanger and separate ones for my power steering and oil coolers.

good luck and will be watching.

Curious how roller rockers do for you. I assume you mean roller tip rockers and not a trunnion upgrade?

Which manifolds did you order? I don’t recall seeing that. Also will you need spacers? I ordered these

https://www.hardin-marine.com/p-1045...-53-60-62.aspx

Yah that alpha will make things a little easier from raw water pickup point of view.

i like that that my manifolds are aluminum. I hate that I’ll have to mill my own spacers out of aluminum but such is life.

I ended up using ict and michiganmotorz for coil extenders and relocation brackets for my coils to go on transom.

im going bravo 3 and I ended up needing the shift bracket thing 807962a15

dont overlook your cooling system. I have a crusader RA0147048a for my heat exchanger and separate ones for my power steering and oil coolers.

good luck and will be watching.

#24

Registered

Thread Starter

well 1 season should be fine but that will put more wear than expected on it from what Iím told (it does make sense).

Curious how roller rockers do for you. I assume you mean roller tip rockers and not a trunnion upgrade?

Which manifolds did you order? I donít recall seeing that. Also will you need spacers? I ordered these

https://www.hardin-marine.com/p-1045...-53-60-62.aspx

Yah that alpha will make things a little easier from raw water pickup point of view.

i like that that my manifolds are aluminum. I hate that Iíll have to mill my own spacers out of aluminum but such is life.

I ended up using ict and michiganmotorz for coil extenders and relocation brackets for my coils to go on transom.

im going bravo 3 and I ended up needing the shift bracket thing 807962a15

dont overlook your cooling system. I have a crusader RA0147048a for my heat exchanger and separate ones for my power steering and oil coolers.

good luck and will be watching.

Curious how roller rockers do for you. I assume you mean roller tip rockers and not a trunnion upgrade?

Which manifolds did you order? I donít recall seeing that. Also will you need spacers? I ordered these

https://www.hardin-marine.com/p-1045...-53-60-62.aspx

Yah that alpha will make things a little easier from raw water pickup point of view.

i like that that my manifolds are aluminum. I hate that Iíll have to mill my own spacers out of aluminum but such is life.

I ended up using ict and michiganmotorz for coil extenders and relocation brackets for my coils to go on transom.

im going bravo 3 and I ended up needing the shift bracket thing 807962a15

dont overlook your cooling system. I have a crusader RA0147048a for my heat exchanger and separate ones for my power steering and oil coolers.

good luck and will be watching.

For the manifolds I ordered the crusader/pcm ones and have plans to make custom stainless risers to mate to the merc y pipe. I have concerns that if I buy the crusader risers I wont be able to make it work with the merc y pipe. I should have enough stainless left over from other projects that im at least going to give it a try fabricating the risers. If it doesnt work I will re evaluate.

#25

Registered

Thread Starter

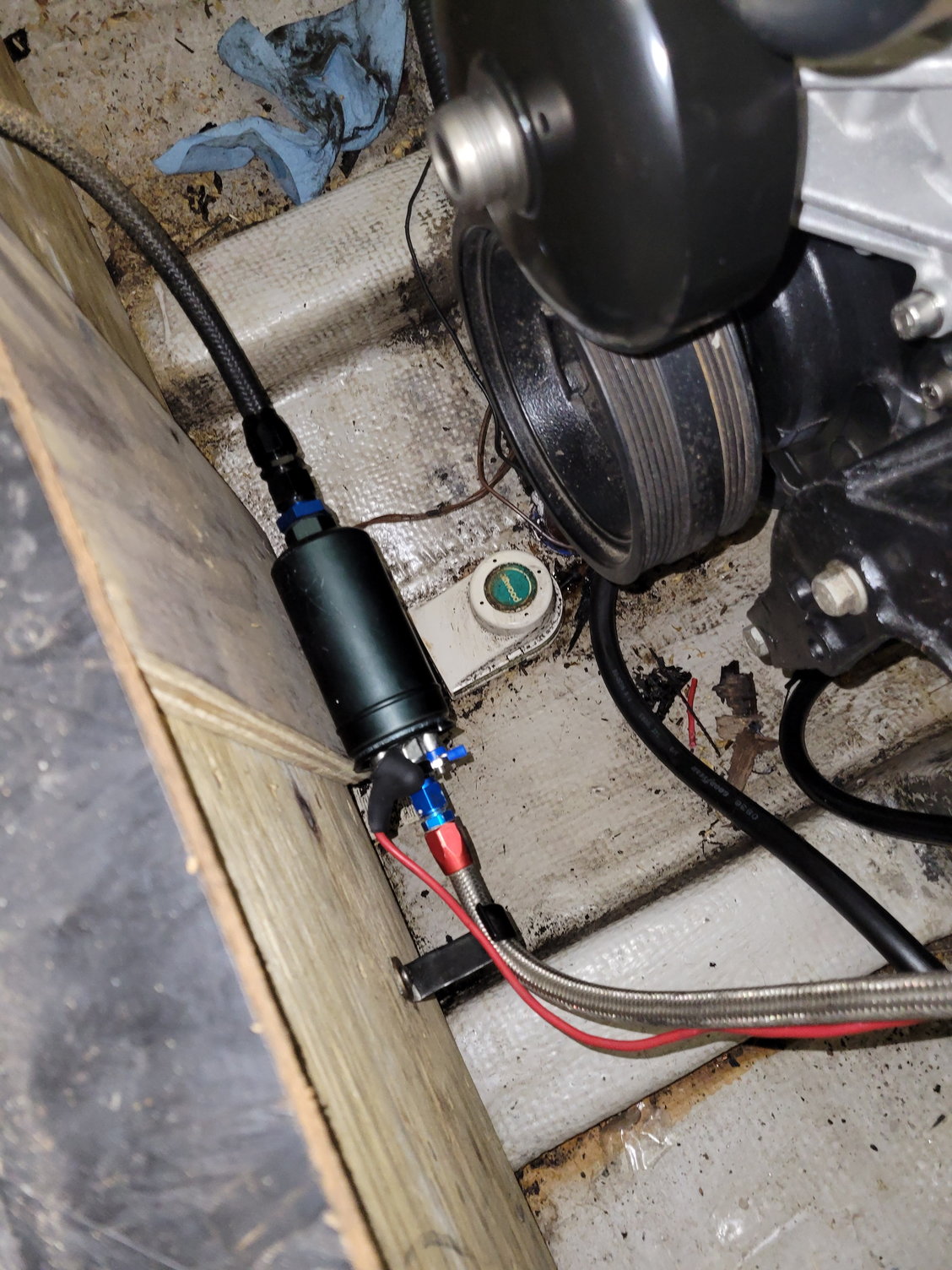

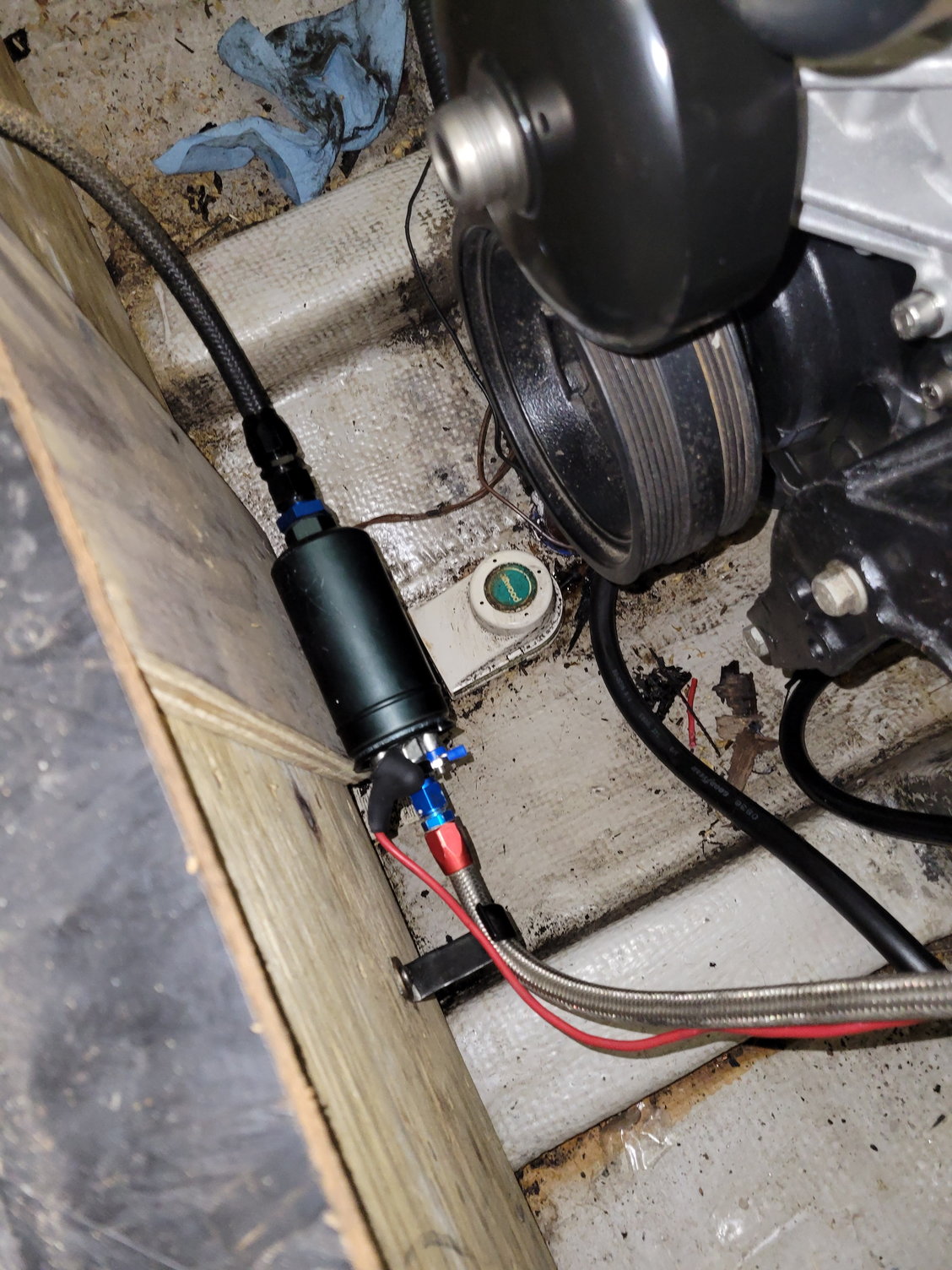

I got the fuel system mostly in place, I just need a fuel/water separator and a filter to go before the pump yet. The way I have it mounted the pump is almost level with the bottom of the fuel tank so I am hoping for no cavitation issues. The fuel pump is mostly wired as well, it is getting powered by a relay that gets triggered via a signal wire from the computer. For plumbing I have -8an from the tank to the pump, then -6an from the pump to the rail, and then the return is -8an. I was going to do the whole system in -8 but I could only get a -6 fitting to fit between the fuel rail and the alternator.

I also got some SBC to LS motor mount adapter plates and they worked out great. The motor is now mounted, but I don't have the new flywheel yet so it is not aligned.

I also got some SBC to LS motor mount adapter plates and they worked out great. The motor is now mounted, but I don't have the new flywheel yet so it is not aligned.

#26

Registered

I have read through there threads many times, they are very informative. I got a good deal on an AEM 50-1005 pump off the facebook marketplace that im going to at least use to get the boat running. Eventually I will get a USCG approved fuel pump and keep the AEM one on the boat as a spare.

https://www.cpperformance.com/p-1008...fuel-pump.aspx

#27

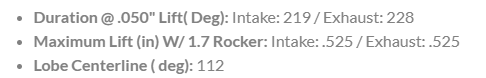

I have not kept up with the ls engine stuff for some time now, I was curious as to how aggressive the ls9 cam will be in that 5.3? only reason I am asking is because you are planning to run manifolds. I just hope you do not run into a reversion issue. I would also recommend getting that fuel pump higher up and not in the bottom of the bilge where it is sure to get wet.

Is that fuel pump safe to use in an enclosed bilge?

Is that fuel pump safe to use in an enclosed bilge?

#28

fuel pump is safe as itís been used by many on swaps and I believe it is uscg approved as mentioned above.

Selecting a cam is tough. I was told by multiple sources not to exceed .227 on a cam. Reason being aggressive cams will cause reversion with both valves being open at BDC and creating a vacuum in turn causing reversion.

Not sure on the specs by OP but so far seems reasonable.

I used tspís high lift truck cam stage 2. Think my specs were 212/218. Multiple experts recommended a truck type cam so I didnít lose torque down low where I need it but want power out on top.

Selecting a cam is tough. I was told by multiple sources not to exceed .227 on a cam. Reason being aggressive cams will cause reversion with both valves being open at BDC and creating a vacuum in turn causing reversion.

Not sure on the specs by OP but so far seems reasonable.

I used tspís high lift truck cam stage 2. Think my specs were 212/218. Multiple experts recommended a truck type cam so I didnít lose torque down low where I need it but want power out on top.

#29

Registered

Thread Starter

I have not kept up with the ls engine stuff for some time now, I was curious as to how aggressive the ls9 cam will be in that 5.3? only reason I am asking is because you are planning to run manifolds. I just hope you do not run into a reversion issue. I would also recommend getting that fuel pump higher up and not in the bottom of the bilge where it is sure to get wet.

Is that fuel pump safe to use in an enclosed bilge?

Is that fuel pump safe to use in an enclosed bilge?

The picture is a little deceiving on the fuel pump, it's about 6" above the stringers yet. Ill be honest though I did not think of water in the bilge when I put it there so I probably will mount it higher yet. My main focus was low as possible to prevent cavitation.

#30

Registered

Thread Starter

fuel pump is safe as itís been used by many on swaps and I believe it is uscg approved as mentioned above.

Selecting a cam is tough. I was told by multiple sources not to exceed .227 on a cam. Reason being aggressive cams will cause reversion with both valves being open at BDC and creating a vacuum in turn causing reversion.

Not sure on the specs by OP but so far seems reasonable.

I used tspís high lift truck cam stage 2. Think my specs were 212/218. Multiple experts recommended a truck type cam so I didnít lose torque down low where I need it but want power out on top.

Selecting a cam is tough. I was told by multiple sources not to exceed .227 on a cam. Reason being aggressive cams will cause reversion with both valves being open at BDC and creating a vacuum in turn causing reversion.

Not sure on the specs by OP but so far seems reasonable.

I used tspís high lift truck cam stage 2. Think my specs were 212/218. Multiple experts recommended a truck type cam so I didnít lose torque down low where I need it but want power out on top.