Engine mount help needed please.

#21

#22

Registered

I'm in the mist of a rebuild on my 502Mag as well and it has the original pedestal mounts as well. My Portside stringer was rotted, the factory mounts were just lagged into he stringer with NO type of sealant. I think the exhaust drain was leaking or the manifold was cracked when the previous owner had the boat it ran down the mount and the stringer just soaked it up.

I am going to get a set of the highway robbery billet mounts but I want to cap the stringer.

My question is how to go about this, I figure a thick aluminum cap and through bolt it to the stringer sandwiching it but how do I secure the pedestal mount the aluminum cap without going through into the stringer? I thought about welding studs to the cap but not possible unless I make the cap out of stainless. If I through bolt it do I clearance the stringer for th bolt head beneath the plate so it recesses into the stringer?

How has this been done?

#23

VIP Member

I'm in the mist of a rebuild on my 502Mag as well and it has the original pedestal mounts as well. My Portside stringer was rotted, the factory mounts were just lagged into he stringer with NO type of sealant. I think the exhaust drain was leaking or the manifold was cracked when the previous owner had the boat it ran down the mount and the stringer just soaked it up.

I am going to get a set of the highway robbery billet mounts but I want to cap the stringer.

My question is how to go about this, I figure a thick aluminum cap and through bolt it to the stringer sandwiching it but how do I secure the pedestal mount the aluminum cap without going through into the stringer? I thought about welding studs to the cap but not possible unless I make the cap out of stainless. If I through bolt it do I clearance the stringer for th bolt head beneath the plate so it recesses into the stringer?

How has this been done?

Flat head machine screws. Drill and tap the aluminum cap for the flat head screws and countersink from the underside, so the flat head machine screw seats flush when tightened. Drill and tap from the sides of the cap for set screws to keep the flat head screws from turning. Lock everything together. and mount to stringers. These will present as studs to mount the pedestals to with hex nuts.

Thanks. Brad.

(937)545-8991

Last edited by Brad Christy; 02-10-2023 at 08:43 AM.

#25

VIP Member

Assuming there is room for the stack-up.....

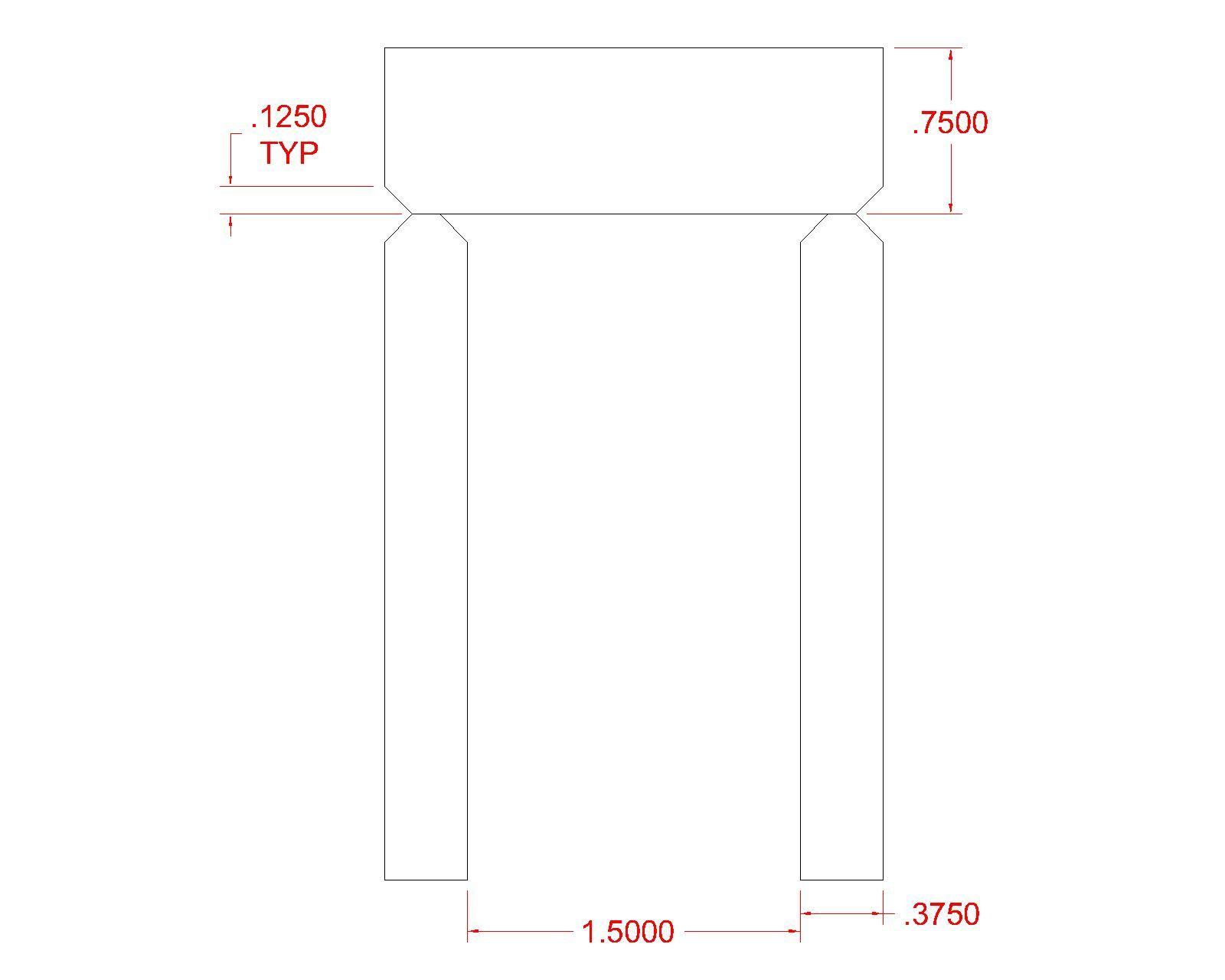

If I were doing my own, I'd use 3/8" screws, make the cap plate 3/4" thick and the side plates either 3/8" or 1/2". The 3/4" thick plate will leave plenty of material to support the flat head screw heads and for the set screws. If there is clearance in the pedestal mount mounting holes, I'd go bigger with the screws and the cap plate.

I would also clamp the side plates to your stringers and tack weld the cap to them so the gap between the side plates is perfect. You can remove and finish weld them later; the more weld the better. You would also do well having them anodized before final install.

If you need help with the machining of the cap plates, I got a guy..... 🙄

Thanks. Brad.

(937)545-8991

Last edited by Brad Christy; 02-10-2023 at 10:34 AM.

#26

Registered

I have to take some measurements to make sure the 3/4" of added plate can be accounted for in lowering the mount adjustment so the engine angle is not wacked to the drive. If not I will have to notch the stringer, reglass and account for the added height that way.

#27

VIP Member

From the pics on this thread, it would appear you would have enough. Obviously, those aren't your mounts, so, yes, you have to take some measurements. Do you still have the mounts you pulled out? Are you planning on reusing them?

There are other ways of keying the FHCSs so they don't rotate if you need to go thinner than will allow for the set screws.

Thanks. Brad.

(937)545-8991

#28

Registered

Joey,

From the pics on this thread, it would appear you would have enough. Obviously, those aren't your mounts, so, yes, you have to take some measurements. Do you still have the mounts you pulled out? Are you planning on reusing them?

There are other ways of keying the FHCSs so they don't rotate if you need to go thinner than will allow for the set screws.

Thanks. Brad.

(937)545-8991

From the pics on this thread, it would appear you would have enough. Obviously, those aren't your mounts, so, yes, you have to take some measurements. Do you still have the mounts you pulled out? Are you planning on reusing them?

There are other ways of keying the FHCSs so they don't rotate if you need to go thinner than will allow for the set screws.

Thanks. Brad.

(937)545-8991

The cap plates are they being made out of 3 plates welded together since I am not sure if a 3/4" plate can be bent 3 times to form a cap to slide down over the stringer?

#29

VIP Member

I do have the originals and I have the bottom nuts locked in position to where engine height was. I am not re-using them I wanted to toss in a set of billets but I know y height to adjust the new ones too.

The cap plates are they being made out of 3 plates welded together since I am not sure if a 3/4" plate can be bent 3 times to form a cap to slide down over the stringer?

The cap plates are they being made out of 3 plates welded together since I am not sure if a 3/4" plate can be bent 3 times to form a cap to slide down over the stringer?

No. You will never bend 3/4" aluminum plate to fit the stringers. I'd make the cap plate as wide as the stack up of the stringer plus your two side plates, finish the machining on the cap plate, then weld the side plates to it.

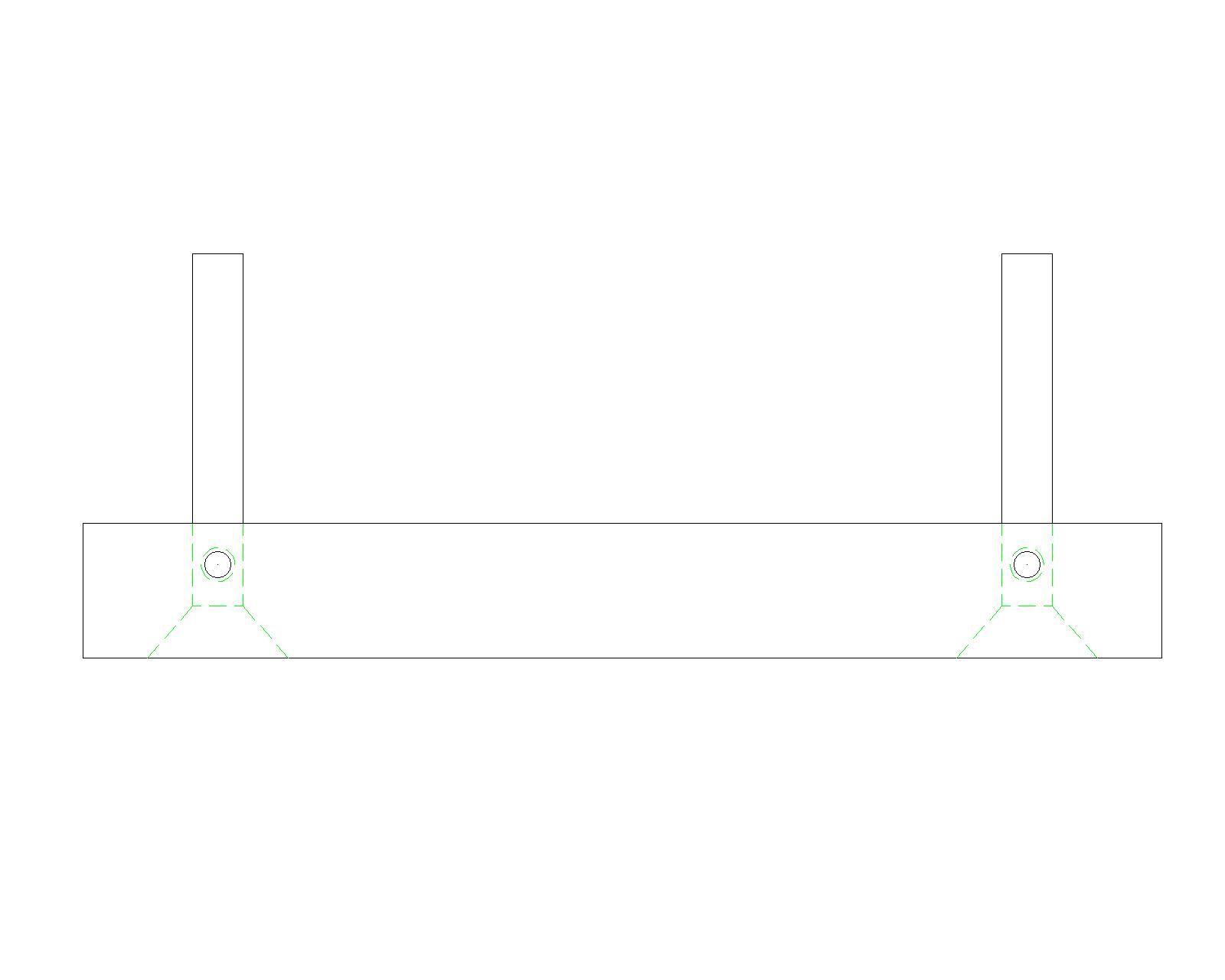

Something like this:

There are some presumptions in this pic, as far as dimensions go, like the width of your stringer, but you get the idea. A decent welder should be able to electric glue this thing together for you pretty well. I would definitely go for a full perimeter weld of both side plates to the cap plate.

Thanks. Brad.

(937)545-8991