Piston ring material

#1

Just wornding what piston ring material would be best for me the engine is a gen iv bbc with a 4.530 bore and dart iron eagle heads. Most cylinders are and pretty good shape but a few have minor scuffs and I don't have the tools for measuring out of round nit going to a machine shop as where I live in canada they are way over priced as there's very few so I ordered cast rings because of this but they accidentally sent moly ones and I heard u want a 100% perfect finish for moly rings am I best to send em back and get cast? That and I already Honed it at 220 or 240 grit

These are the rings they sent me Piston Rings, Premium Ductile Ring Sets, Plasma-moly, 1/16 in., 1/16 in., 3/16 in. Thickness, 8-cylinder, Set of 8

These are the rings they sent me Piston Rings, Premium Ductile Ring Sets, Plasma-moly, 1/16 in., 1/16 in., 3/16 in. Thickness, 8-cylinder, Set of 8

Last edited by 502nova3; 06-11-2023 at 04:10 PM.

#2

Registered

You have a 4.530 bore and 4.500 rings? Not going to work well.

#3

I gnore that thats just same ones I got but in std bore I got .035 over gonna file fit em just grabbed that off the intenet just wondering if my cyl may not have the proper finish if im better going with the cast ones that I wanted

The following 2 users liked this post by snapmorgan:

articfriends (06-21-2023), BBYSTWY (06-12-2023)

#5

#6

Registered

Moly rings should seal very quick. I believe the moly is over a cast ring.

The following users liked this post:

articfriends (06-21-2023)

#7

#8

call total seal they are very good they have me running a gap less in a big blown application told me no filled rings as boost will knock the coatings or fillers out watch the end gaps we are running 34 to 35 thou end gap

The following users liked this post:

502nova3 (06-15-2023)

#9

Registered

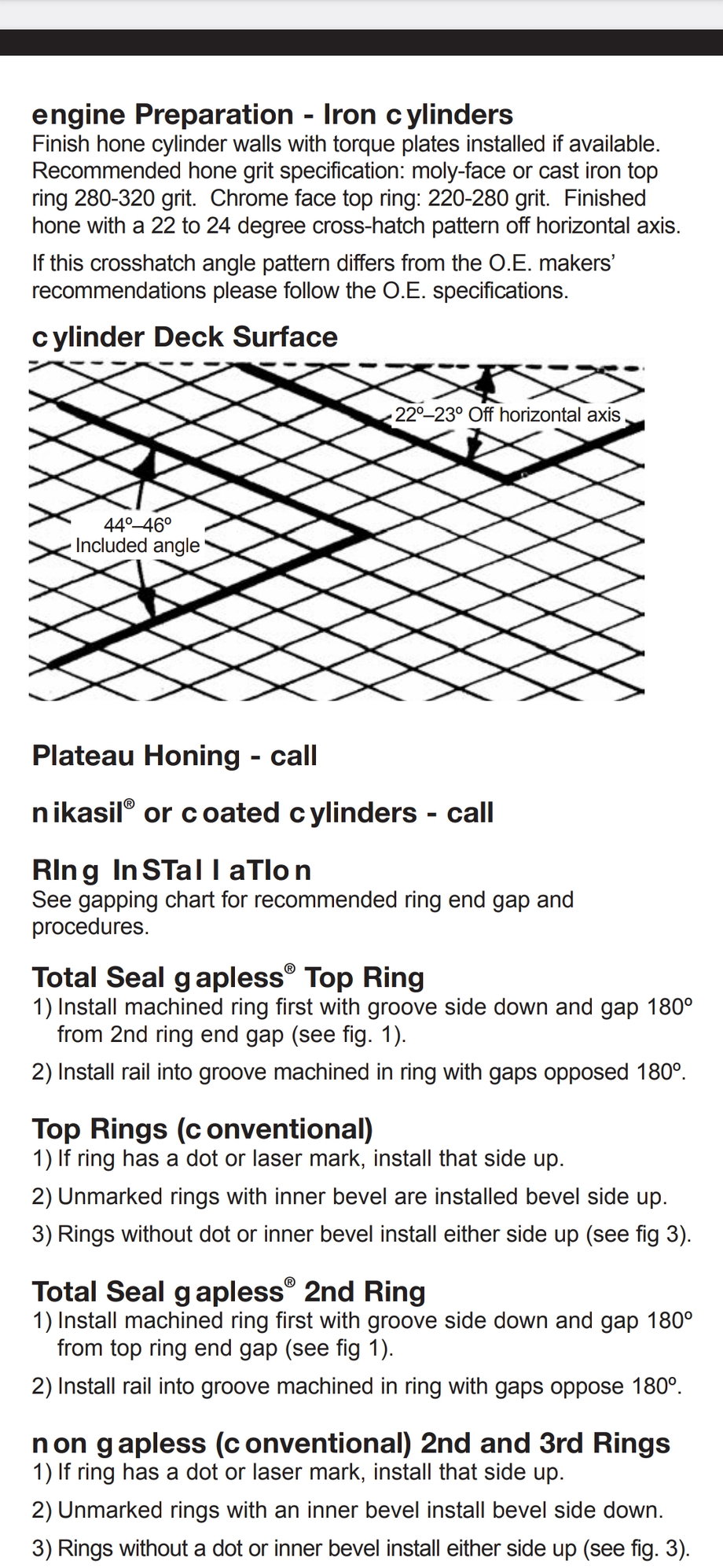

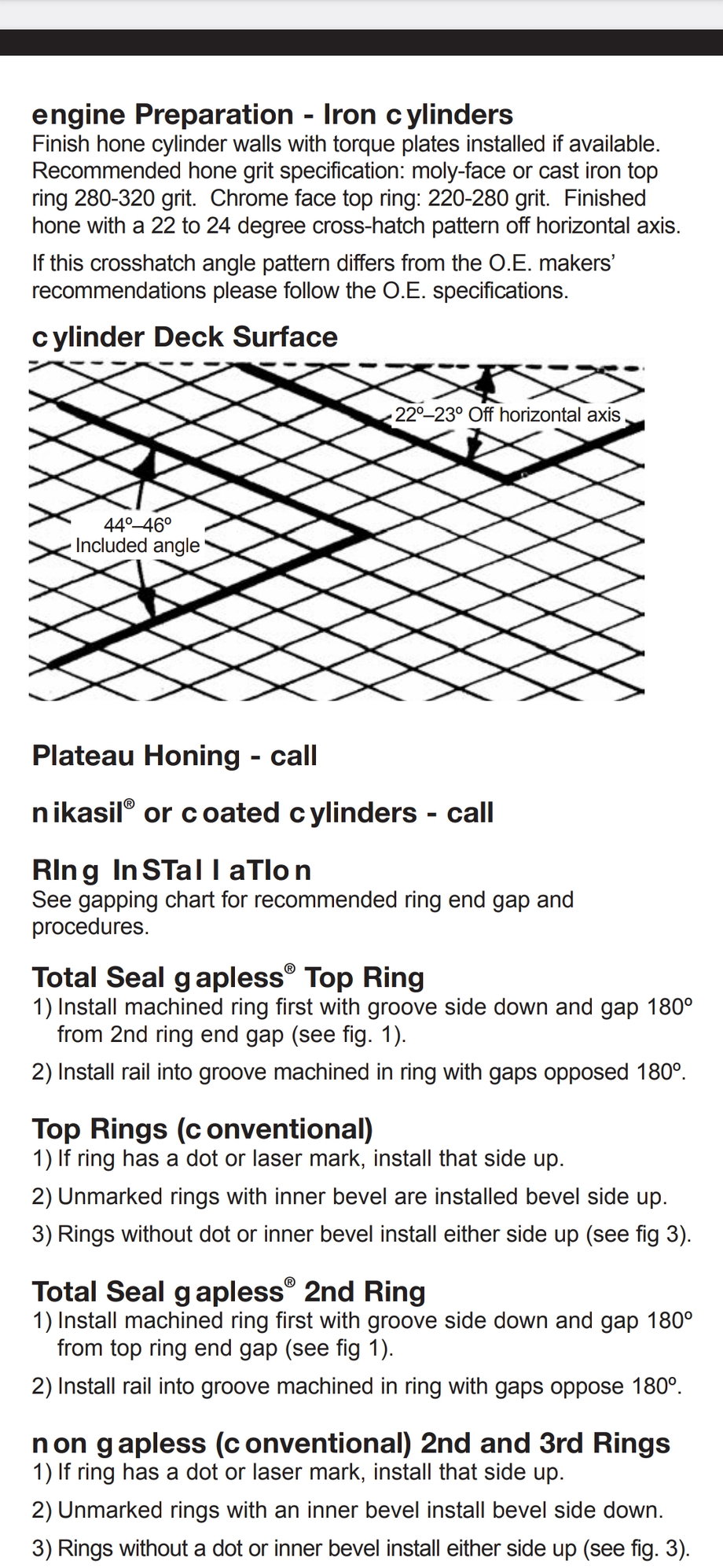

This is Total Seals instructions

I ran moly top ring with 9:1 compression and 30lbs of boost with no issues. You just have to make sure you don't have detonation or it will knock the moly coating off.

I ran moly top ring with 9:1 compression and 30lbs of boost with no issues. You just have to make sure you don't have detonation or it will knock the moly coating off.