Scat 9000 cast crank broke 383 SBC

#21

Registered

(**) Will balance at 1800 grams with external weighted flywheel, neutral balancer & one piece of heavy metal in #1 counterweight.

You said that the crank was internally balanced and you had a neutral balance flywheel on it. That is possible but in order to do it there would probably have to be at least three if not more pieces of heavy metal in the back counterweight and I see no evidence of that in your pictures. Plus there are several fairly large holes drilled in the back counterweight which make no sense if it was internal balance. And there should probably be one piece in the front. 1800 grams is a fairly typical small block bobweight so you should be close to their target.

I would think that you would feel some obvious vibration if it was that badly out of balance but in a boat sometimes its very hard to tell. I know of guys who have made the same mistake in car engines and not really had a terrible vibration.

Do you happen to have a copy of the balance card from whoever did the balancing ?

Also, that is right about where I would expect it to break under those conditions.

And just for credibility sake because you don't know me from Adam . . . . I just balanced my 1000th crankshaft earlier this year so I have a little bit of experience balancing.

Also, I am not defending any manufacturer etc etc . . . just want to help you get to the bottom of this unusual failure. And make sure it doesn't happen again

Last edited by BillK; 07-01-2023 at 09:32 AM.

#22

Registered

And that is my theory of what happened. That crankshaft is designed to be externally balance on the back and internal on the front depending on the bobweight. This is from the Scat catalog

(**) Will balance at 1800 grams with external weighted flywheel, neutral balancer & one piece of heavy metal in #1 counterweight.

You said that the crank was internally balanced and you had a neutral balance flywheel on it. That is possible but in order to do it there would probably have to be at least three if not more pieces of heavy metal in the back counterweight and I see no evidence of that in your pictures. Plus there are several fairly large holes drilled in the back counterweight which make no sense if it was internal balance. And there should probably be one piece in the front. 1800 grams is a fairly typical small block bobweight so you should be close to their target.

I would think that you would feel some obvious vibration if it was that badly out of balance but in a boat sometimes its very hard to tell. I know of guys who have made the same mistake in car engines and not really had a terrible vibration.

Do you happen to have a copy of the balance card from whoever did the balancing ?

Also, that is right about where I would expect it to break under those conditions.

And just for credibility sake because you don't know me from Adam . . . . I just balanced my 1000th crankshaft earlier this year so I have a little bit of experience balancing.

Also, I am not defending any manufacturer etc etc . . . just want to help you get to the bottom of this unusual failure. And make sure it doesn't happen again

(**) Will balance at 1800 grams with external weighted flywheel, neutral balancer & one piece of heavy metal in #1 counterweight.

You said that the crank was internally balanced and you had a neutral balance flywheel on it. That is possible but in order to do it there would probably have to be at least three if not more pieces of heavy metal in the back counterweight and I see no evidence of that in your pictures. Plus there are several fairly large holes drilled in the back counterweight which make no sense if it was internal balance. And there should probably be one piece in the front. 1800 grams is a fairly typical small block bobweight so you should be close to their target.

I would think that you would feel some obvious vibration if it was that badly out of balance but in a boat sometimes its very hard to tell. I know of guys who have made the same mistake in car engines and not really had a terrible vibration.

Do you happen to have a copy of the balance card from whoever did the balancing ?

Also, that is right about where I would expect it to break under those conditions.

And just for credibility sake because you don't know me from Adam . . . . I just balanced my 1000th crankshaft earlier this year so I have a little bit of experience balancing.

Also, I am not defending any manufacturer etc etc . . . just want to help you get to the bottom of this unusual failure. And make sure it doesn't happen again

#23

Registered

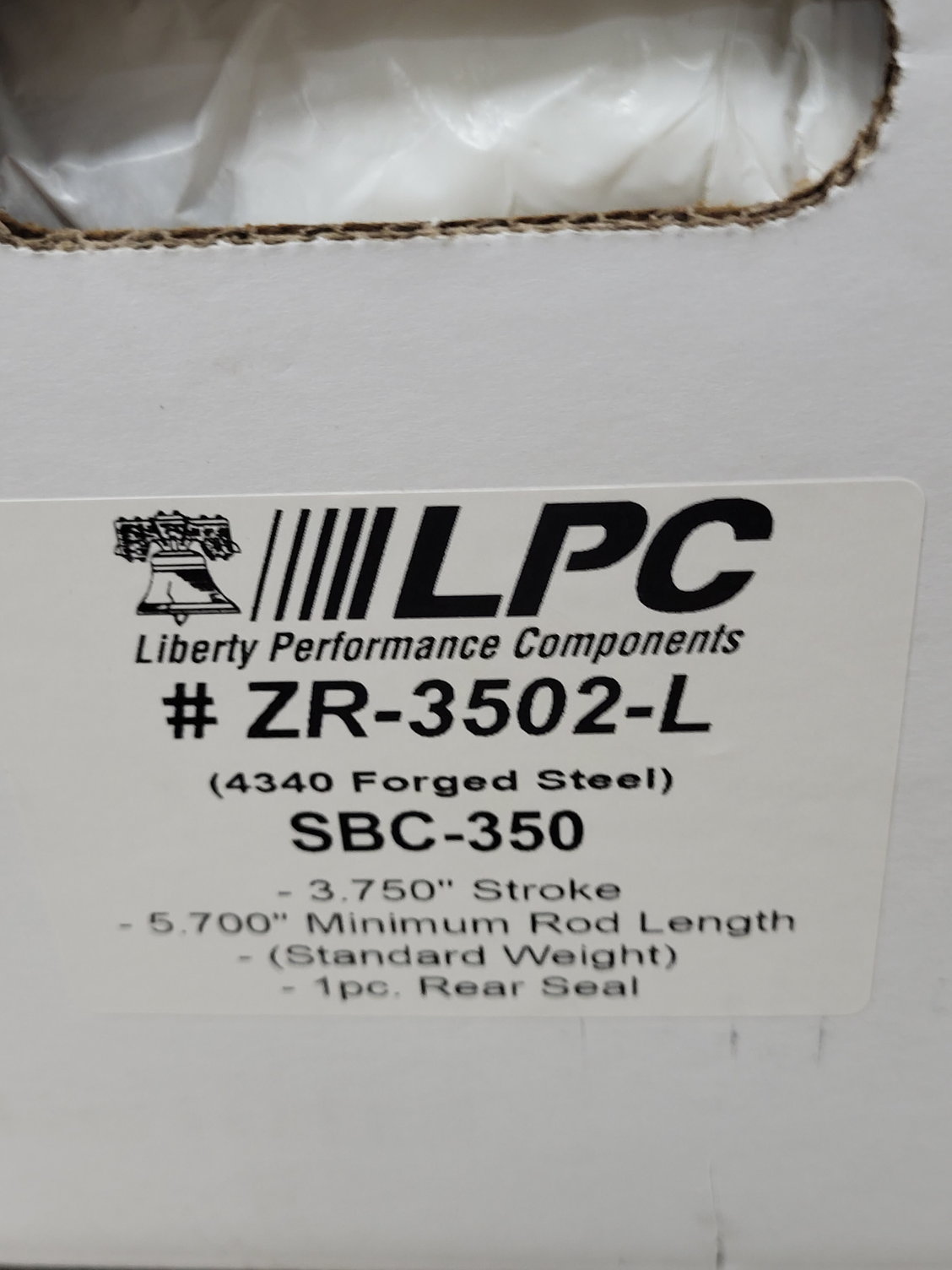

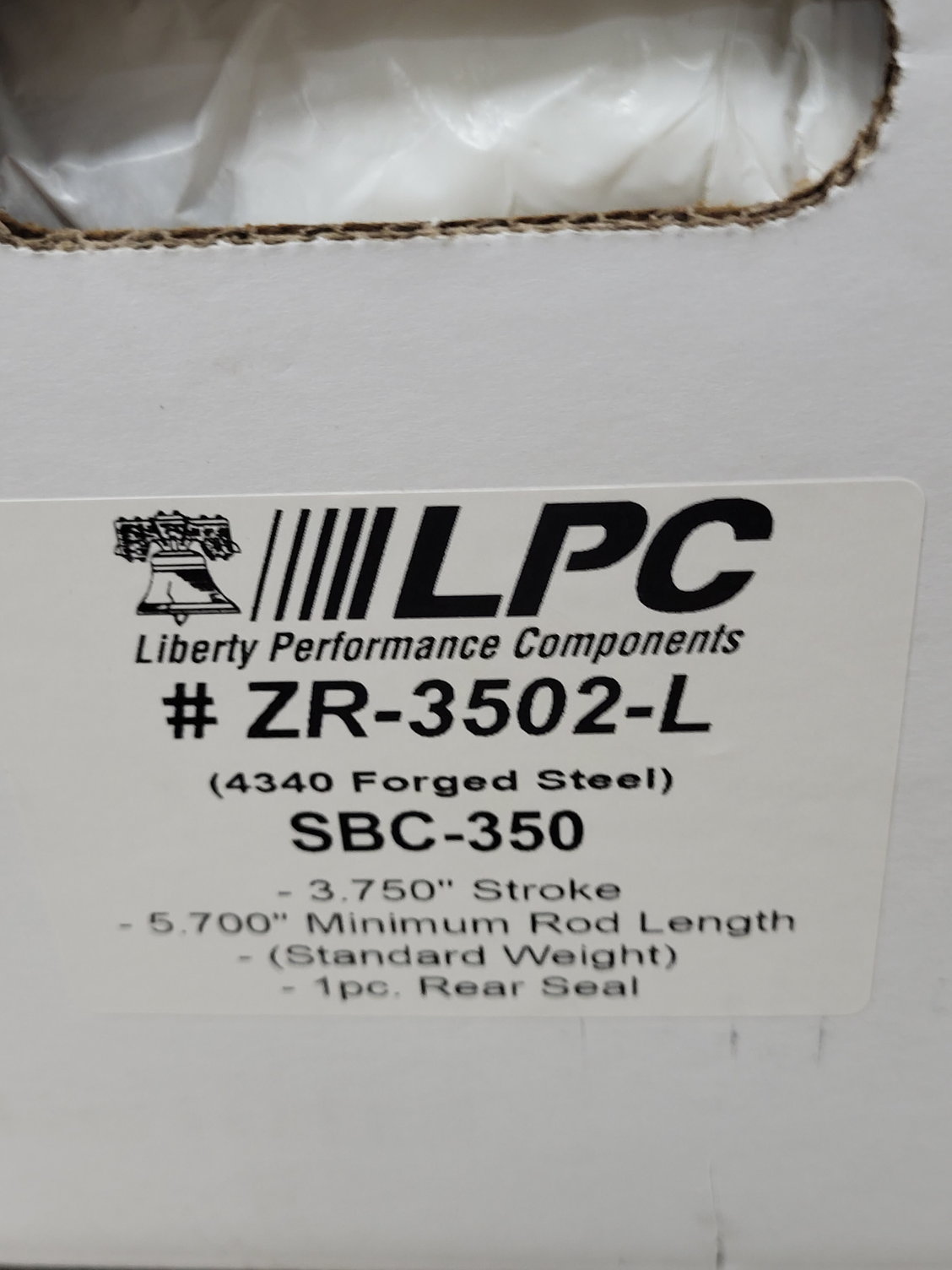

I am only going by what Paxton said. Maybe he could post the part number off the front counterweight to be sure. It should be 9-350-3750-5700-L

And I agree that there should have been an obvious vibration but I have had guys put a neutral flywheel on a 383 before and swear there was only a slight vibration.

The following users liked this post:

SB (07-02-2023)

#26

Registered

Thread Starter

So, I checked my flywheel, it does have weight on it.

The engine was internal front / external rear balanced. The assembly was balanced with the stock 350 harmonic dampener and the stock Mercruiser flywheel installed on the crank. I was there when it was done.

The engine was balanced correctly.

The engine was internal front / external rear balanced. The assembly was balanced with the stock 350 harmonic dampener and the stock Mercruiser flywheel installed on the crank. I was there when it was done.

The engine was balanced correctly.

#27

Registered

So, I checked my flywheel, it does have weight on it.

The engine was internal front / external rear balanced. The assembly was balanced with the stock 350 harmonic dampener and the stock Mercruiser flywheel installed on the crank. I was there when it was done.

The engine was balanced correctly.

I hope you will reach out to Scat and ask them to take a look at it. It might help others in the future.

The following users liked this post:

getrdunn (07-06-2023)

#28

Registered

The following users liked this post:

getrdunn (07-17-2023)

#30

Registered

Thread Starter

Trying again.....bought a forged crank. I test fit it with new standard bearing and it feels great. I don't think there is any damage to the block or rear main.

I had one piston with a busted skirt that smacked the crank when it broke, so I had to buy a whole set. New rings and bearings.

I am collecting parts to get it balanced again.

This crank calls for internal balance front and rear, so I am going to machine the weight off my flywheel.

Beginning to think I should LS swap it.

I had one piston with a busted skirt that smacked the crank when it broke, so I had to buy a whole set. New rings and bearings.

I am collecting parts to get it balanced again.

This crank calls for internal balance front and rear, so I am going to machine the weight off my flywheel.

Beginning to think I should LS swap it.

Last edited by Paxtonspeed; 07-19-2023 at 09:22 AM.

The following users liked this post:

cheech (07-19-2023)