350 SBC updates?

#1

Registered

Thread Starter

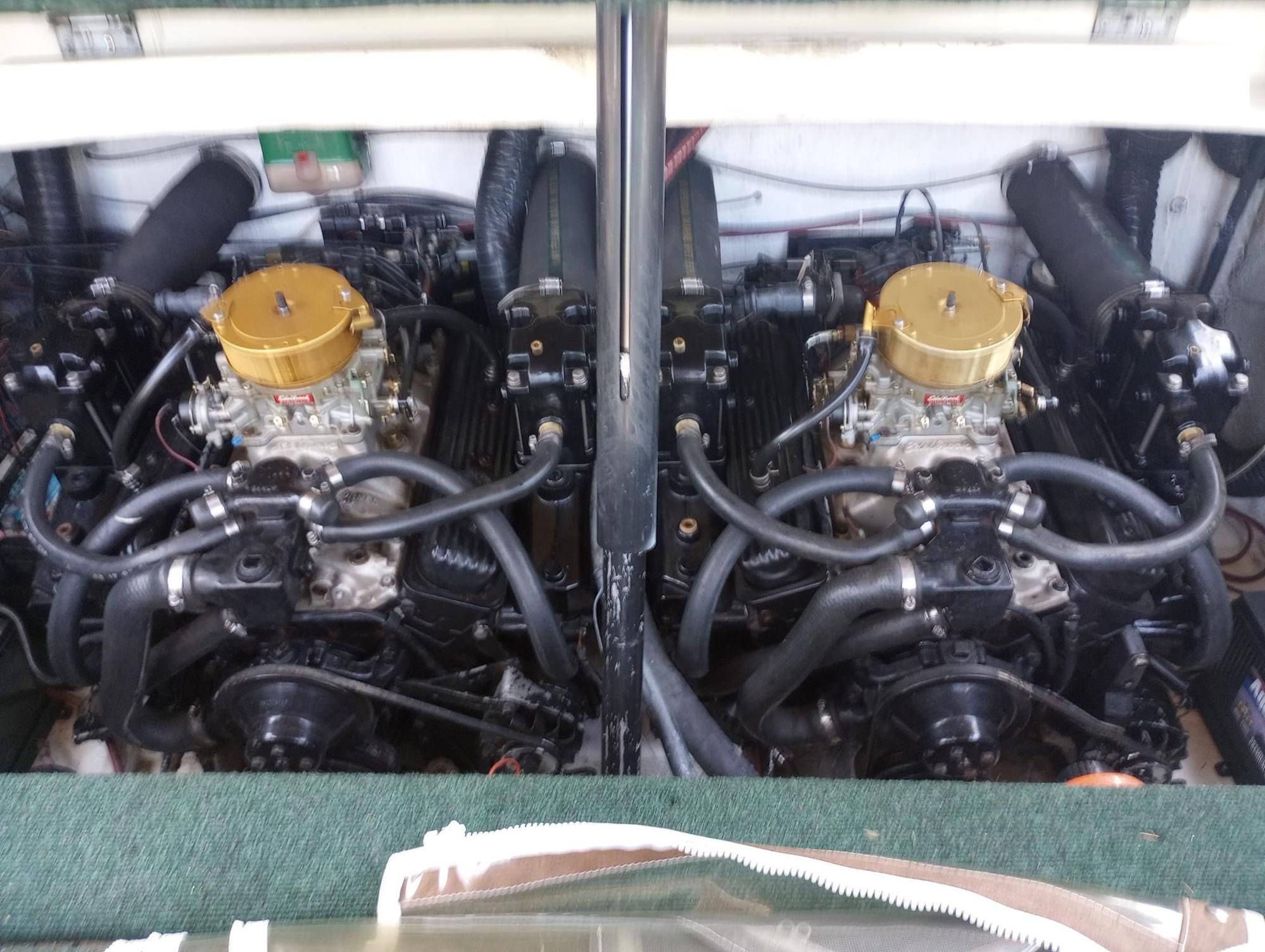

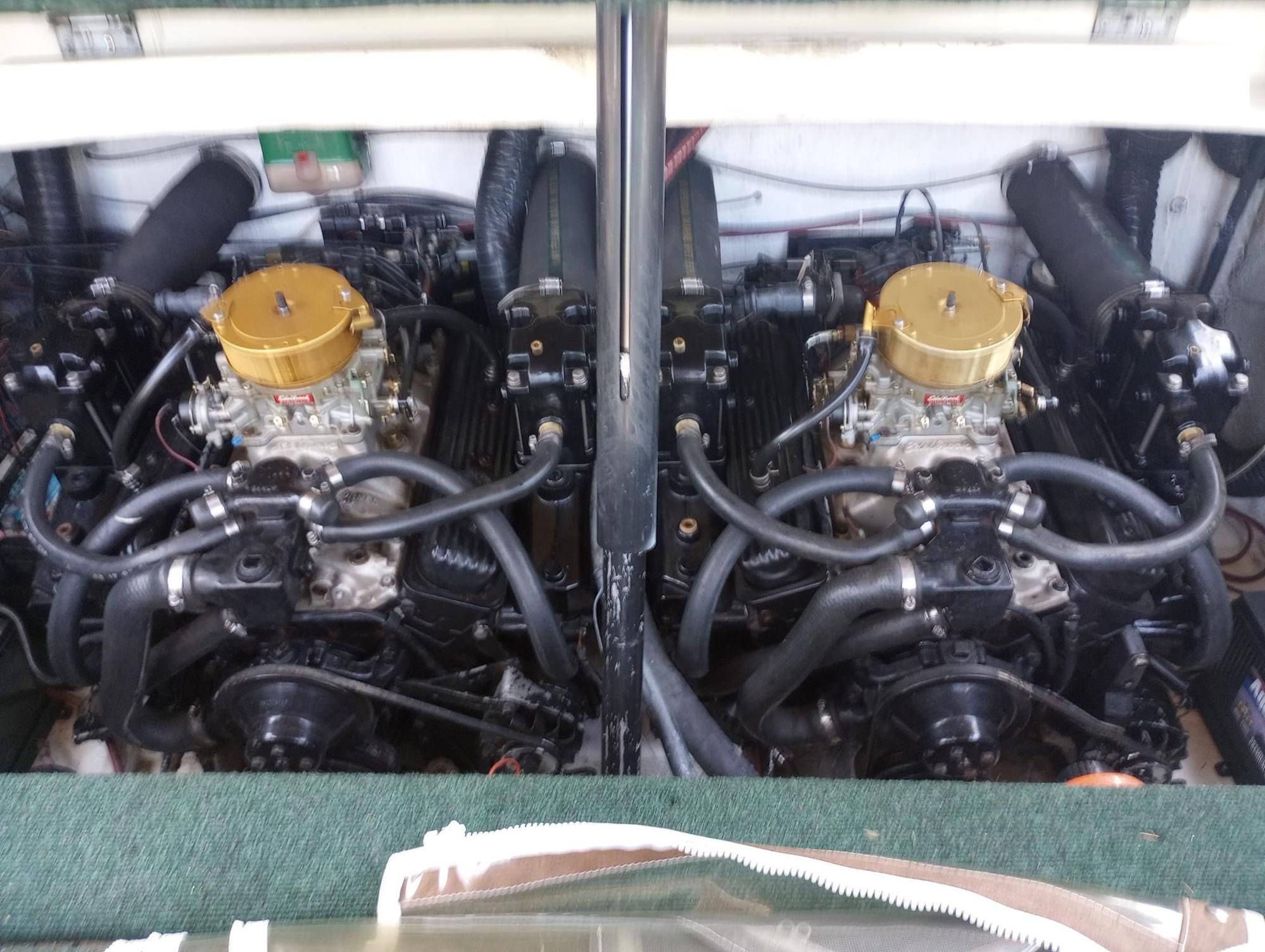

Have a '79 Webbcraft 26' with twin 350's and alpha drives. Love the boat and had a great time this summer. One motor has a slight tic to it and gets a "cough" above 4500 rpm. Hour meter is at 670 and PO said he got is with 350 hrs and rebuilt the motors. Motors were rebuilt a while back (350hrs?) and the paperwork says balanced, 10.5:1 compression, vortec 64cc 1.94/1.50 heads, CS XM 262H-12 comp cams 462/477 lift, Edelbrock 750 carb and performer RPM manifolds, aluminum exhaust manifolds and risers. Still running points ignition. Boat maxed out a 5200 rpm on smooth water with no tabs. Not looking for a race boat, just a good solid sport cruiser.

Going to do a compression test and see what that tells me and pull the valve covers to take a look there. If the compression test comes back good, what upgrades could I make to the upper end? PO said his next move was going with roller rockers next. If the compression test is off then I'll

need to find out if its head or cylinder related. Then there's always those crate 383's out there.....

Thoughts and comments welcomed.

H

Going to do a compression test and see what that tells me and pull the valve covers to take a look there. If the compression test comes back good, what upgrades could I make to the upper end? PO said his next move was going with roller rockers next. If the compression test is off then I'll

need to find out if its head or cylinder related. Then there's always those crate 383's out there.....

Thoughts and comments welcomed.

H

#2

The cough could be ignition (replace points and set dwell and timing, or it could be carb, (lean or rich spot in transition). Nothing wrong with points ignition but a set of DUI marine HEI distributors would be a good upgrade. Tick could be a loose rocker, collapsing lifter. You're on the right track to start with a compression test. 5200 rpm with those heads and that cam is about perfect. If compression test doesn't shed any light, checking for overly loose rocker arm might show a collapsed lifter, or even the possibility of a lifter / cam lobe going bad.

As for upgrades, Imco stainless exhaust riser elbows will give you a little increase over the factory cast risers. Roller rockers won't be a noticeable difference but not a bad investment either. The cam profile you have is a great small block grind for marine and as big as you can go with your current exhaust. The upgrade to hydraulic roller cams would be a 20-30hp gain per engine, but your heads will need some guide work to handle higher lift of a roller cam. Beyond that, jumping to a 180ish cc intake port aluminum head is the next viable upgrade before going into a full build 383cu in. stroker bottom end. You can build a very reliable 425hp / 475 torque marine 383 with budget aluminum heads and a hydraulic roller cam set up. Some of us here have went way beyond that point but reliability and longevity drops quickly with numbers much higher than that....

Let us know what your compression test shows.

As for upgrades, Imco stainless exhaust riser elbows will give you a little increase over the factory cast risers. Roller rockers won't be a noticeable difference but not a bad investment either. The cam profile you have is a great small block grind for marine and as big as you can go with your current exhaust. The upgrade to hydraulic roller cams would be a 20-30hp gain per engine, but your heads will need some guide work to handle higher lift of a roller cam. Beyond that, jumping to a 180ish cc intake port aluminum head is the next viable upgrade before going into a full build 383cu in. stroker bottom end. You can build a very reliable 425hp / 475 torque marine 383 with budget aluminum heads and a hydraulic roller cam set up. Some of us here have went way beyond that point but reliability and longevity drops quickly with numbers much higher than that....

Let us know what your compression test shows.

The following users liked this post:

Ryan00TJ (01-06-2024)

#3

Registered

Tic and cough, if related, could be a valvespring issue or worn (exhaust more likely) cam lobe.

Cough not related to tic could be ignition or carb/fuel supply issue.

As mentioned, Roller rockers won’t make noticeable power gain.

A switch of just cyl heads will prob not move the boat much faster if any.

94sylvan is on point. He knows his marine sbc’s.

Cough not related to tic could be ignition or carb/fuel supply issue.

As mentioned, Roller rockers won’t make noticeable power gain.

A switch of just cyl heads will prob not move the boat much faster if any.

94sylvan is on point. He knows his marine sbc’s.

#4

Registered

Thread Starter

Thanks for the replies, appreciate the feedback and comments. Will see if I can fit the compression test in the next few days before travel....

Looked at the DUI ignition setup as well as some others. I gave away my dwell meter last year during the move figuring I would never need that again..... What timing should I use for a baseline?

Talked with the people at Raptor Engines in Portland OR and they have very reasonable prices of 383's dyno'd and ready to go in the 350-400 hp range. Would really simplify things. Then I wouldn't have to rebuild the Baja's small head 350, just drop in the non-tic motor in that, and have a complete motor for the powerless Taylor flat bottom project.

What exhaust would work will with a solid 383 build?

Thanks again.

H

Looked at the DUI ignition setup as well as some others. I gave away my dwell meter last year during the move figuring I would never need that again..... What timing should I use for a baseline?

Talked with the people at Raptor Engines in Portland OR and they have very reasonable prices of 383's dyno'd and ready to go in the 350-400 hp range. Would really simplify things. Then I wouldn't have to rebuild the Baja's small head 350, just drop in the non-tic motor in that, and have a complete motor for the powerless Taylor flat bottom project.

What exhaust would work will with a solid 383 build?

Thanks again.

H

#5

Registered

Thread Starter

Pulled the exhaust manifolds to gain much easier access to the plugs with the help of my grandson today. Great move on my part as everything came right off. So much nicer with the aluminum manifolds compared with the old cast iron parts on the Baja.

Pulling Exhaust manifolds

Pulled all the plugs and overall looked rich with a few completely black.

Right Side

Left Side

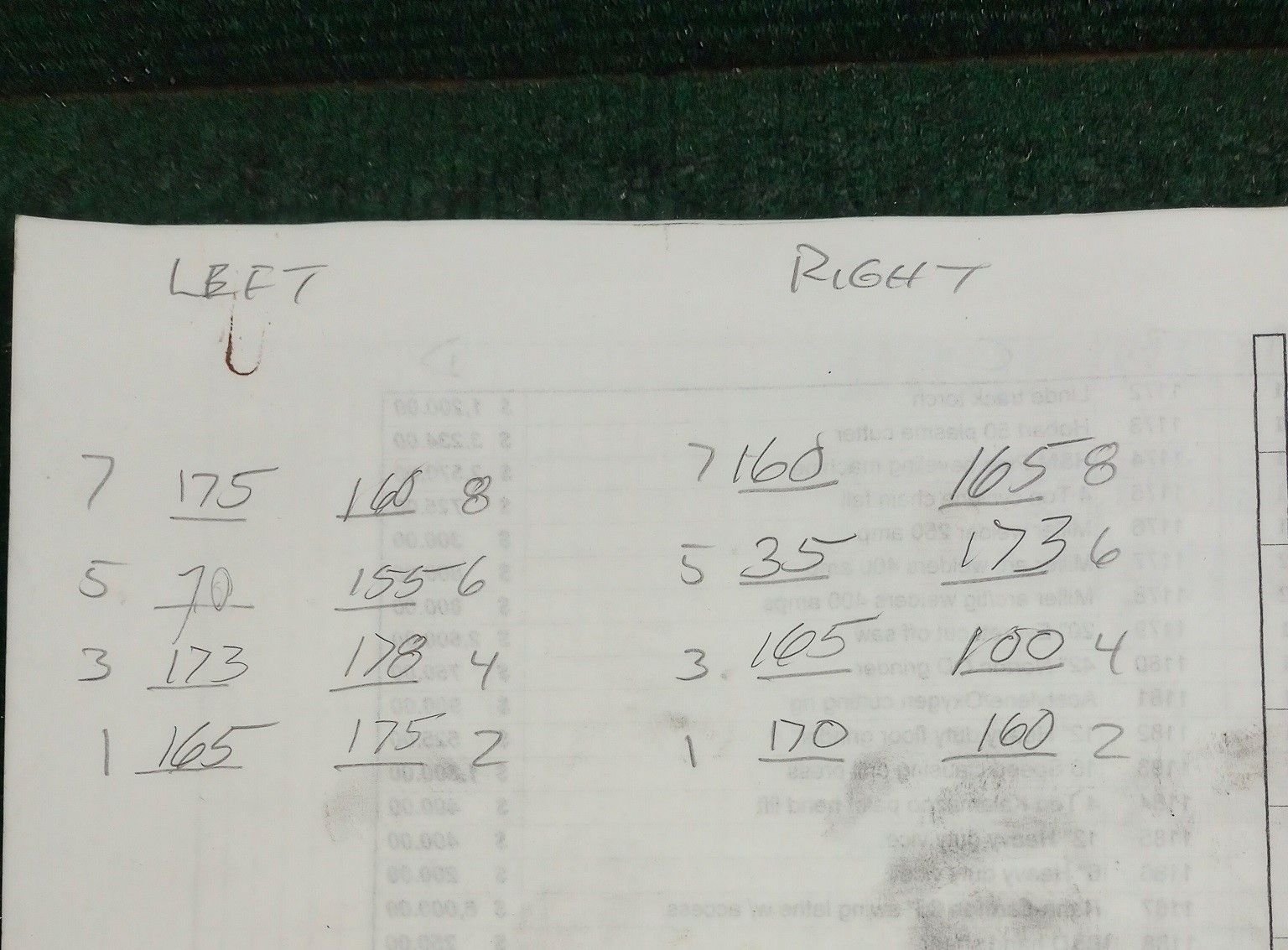

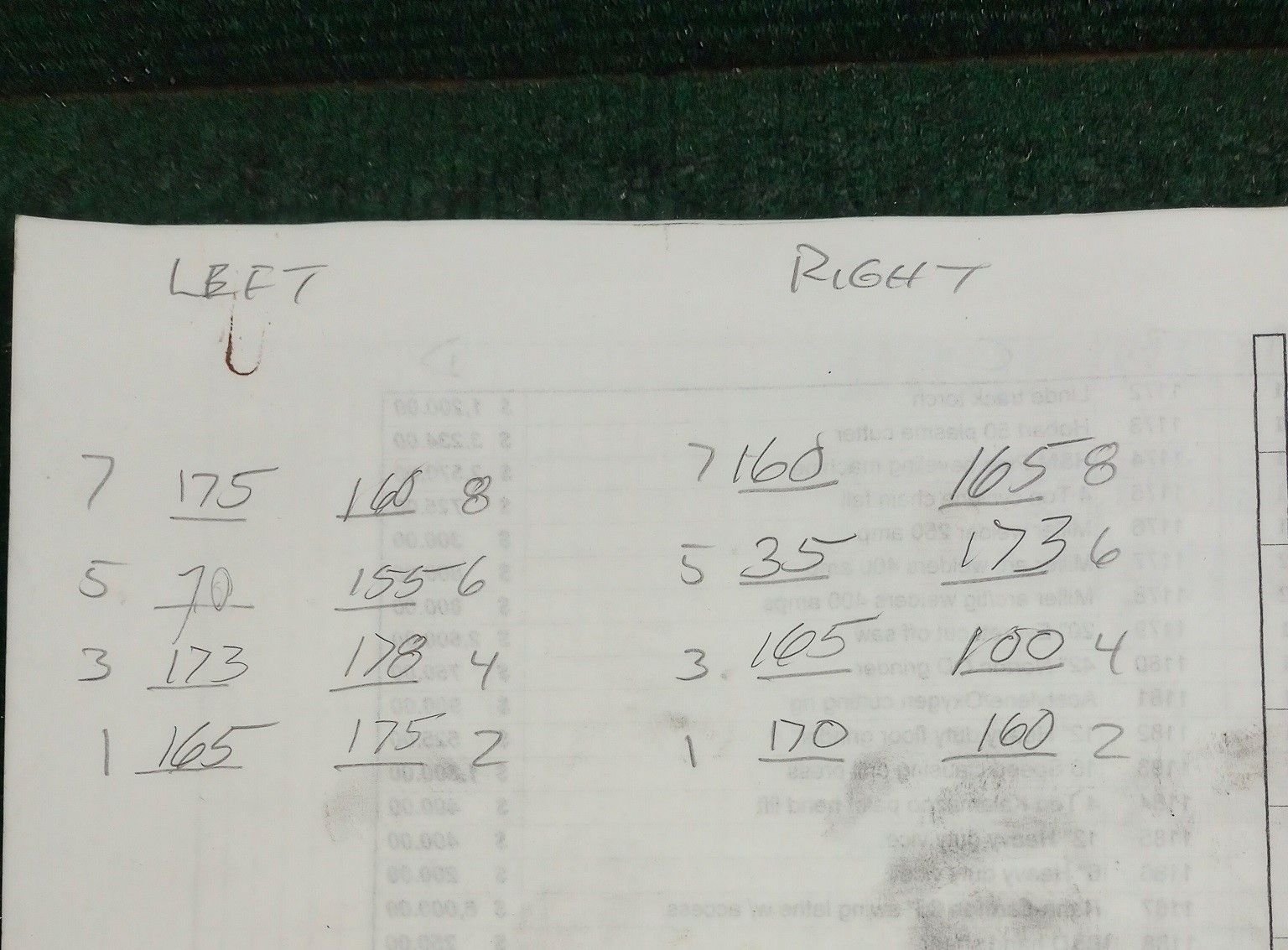

Pulled out the old compression tester, opened up throttles, and cranked about 4 cycles / test.

Compression test results

I was surprised by the 70 lb test on #5 Left Side motor. I couldn't really tell while the motor was running. I figured the right side motor had the tick to it and was also surprised that two cylinders were low, 35 lbs on #5 and 100 on #4. Tomorrow we'll pull the valve covers and start digging into the root cause of the low compression. Hopefully it won't take a month to get to the next step........

Once we find the root cause of the low compression, we'll get a plan on next steps to get it back together.

Pulling Exhaust manifolds

Pulled all the plugs and overall looked rich with a few completely black.

Right Side

Left Side

Pulled out the old compression tester, opened up throttles, and cranked about 4 cycles / test.

Compression test results

I was surprised by the 70 lb test on #5 Left Side motor. I couldn't really tell while the motor was running. I figured the right side motor had the tick to it and was also surprised that two cylinders were low, 35 lbs on #5 and 100 on #4. Tomorrow we'll pull the valve covers and start digging into the root cause of the low compression. Hopefully it won't take a month to get to the next step........

Once we find the root cause of the low compression, we'll get a plan on next steps to get it back together.

#7

Registered

Thread Starter

It was suggested I use proper terms here...

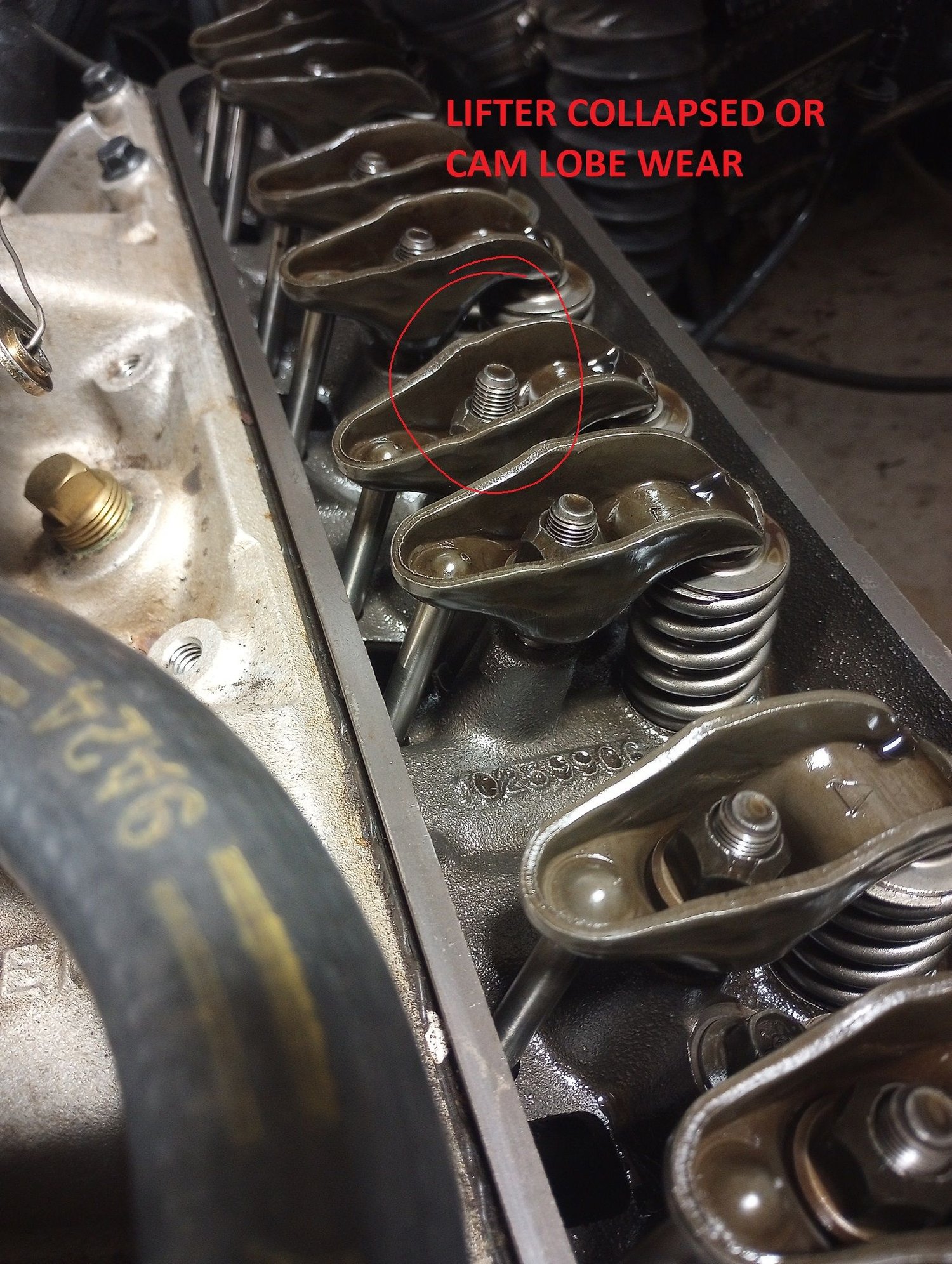

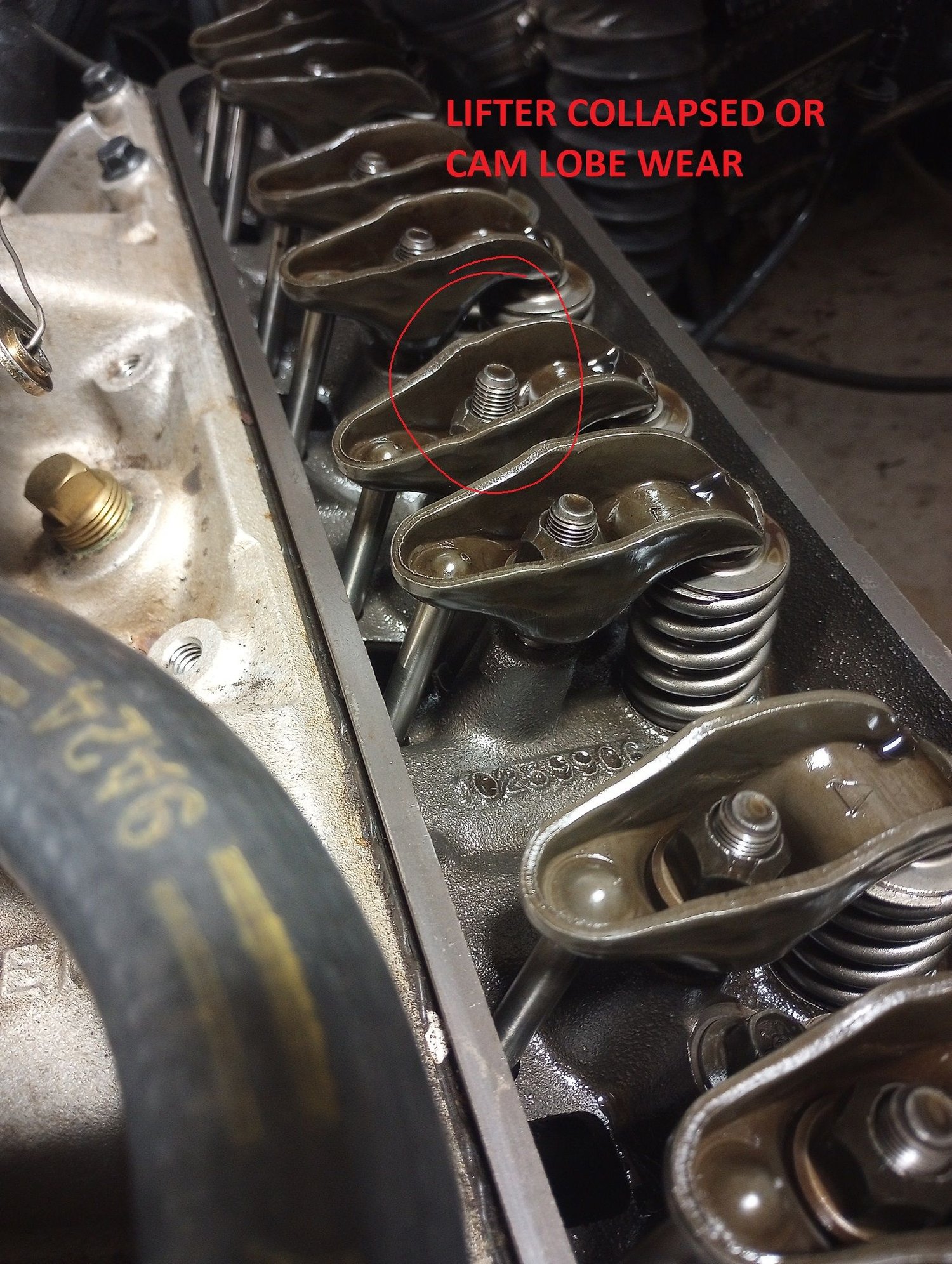

Starboard engine has #5 cyl at 70 lbs. Port side has #4 @ 100 lbs and #5 at 35 lbs compression. Pulled the valve covers and didn't see anything broken or appear to be bent.

Cranked on starboard engine and it looked like valve train was operating OK. Did another compression test and got 75 lbs.

Looked at port engine again and saw where the PO had cranked down the rocker on #4 exhaust. Rolled it over and very little movement on #4 exhaust rocker to the lobe / lifter / pushrod has an issue.

Next move is to pull the intakes and get a better look, but not ready to go that far just yet so we'll save that for next time....

Starboard engine has #5 cyl at 70 lbs. Port side has #4 @ 100 lbs and #5 at 35 lbs compression. Pulled the valve covers and didn't see anything broken or appear to be bent.

Cranked on starboard engine and it looked like valve train was operating OK. Did another compression test and got 75 lbs.

Looked at port engine again and saw where the PO had cranked down the rocker on #4 exhaust. Rolled it over and very little movement on #4 exhaust rocker to the lobe / lifter / pushrod has an issue.

Next move is to pull the intakes and get a better look, but not ready to go that far just yet so we'll save that for next time....

#8

Registered

Thread Starter

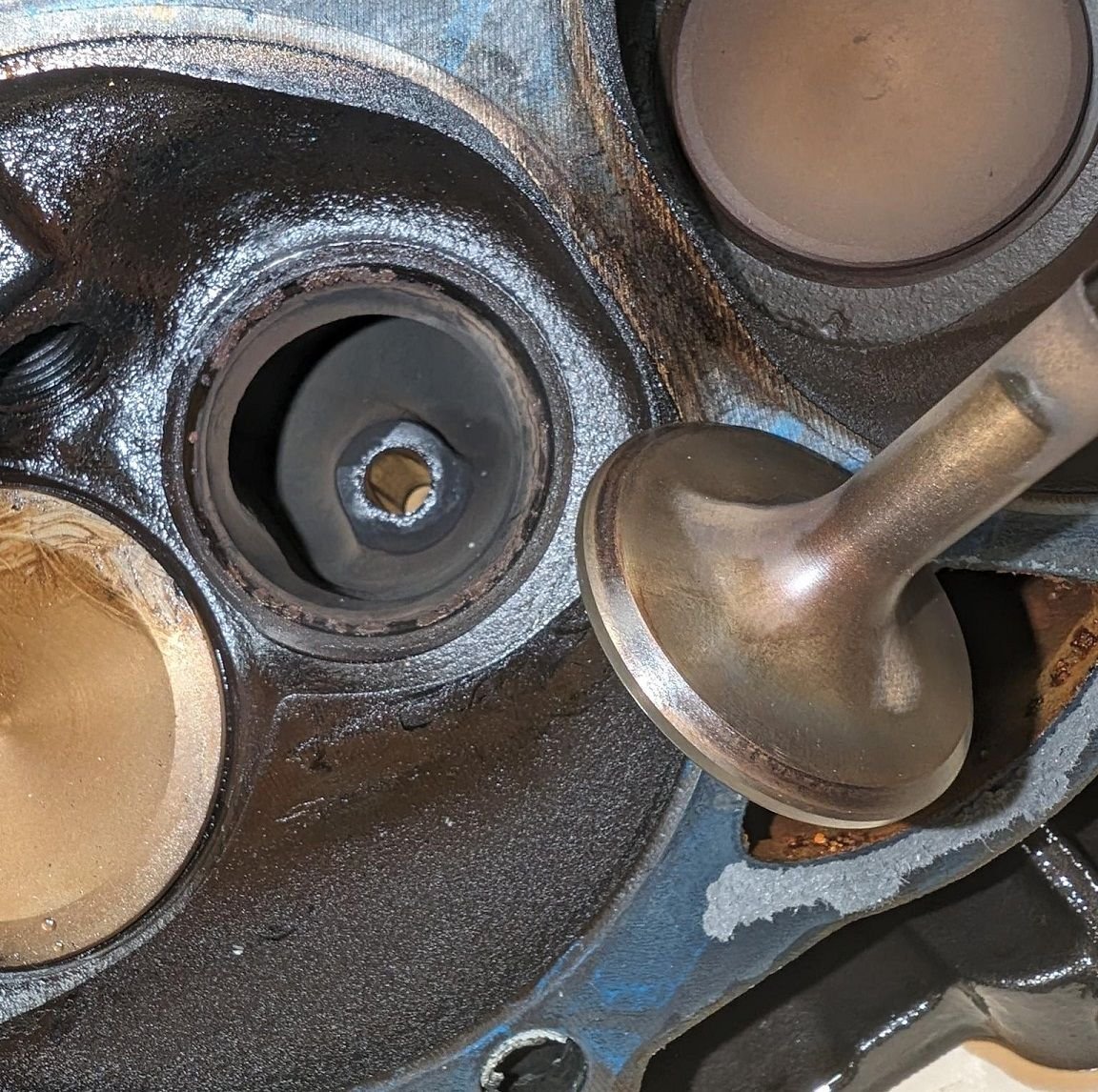

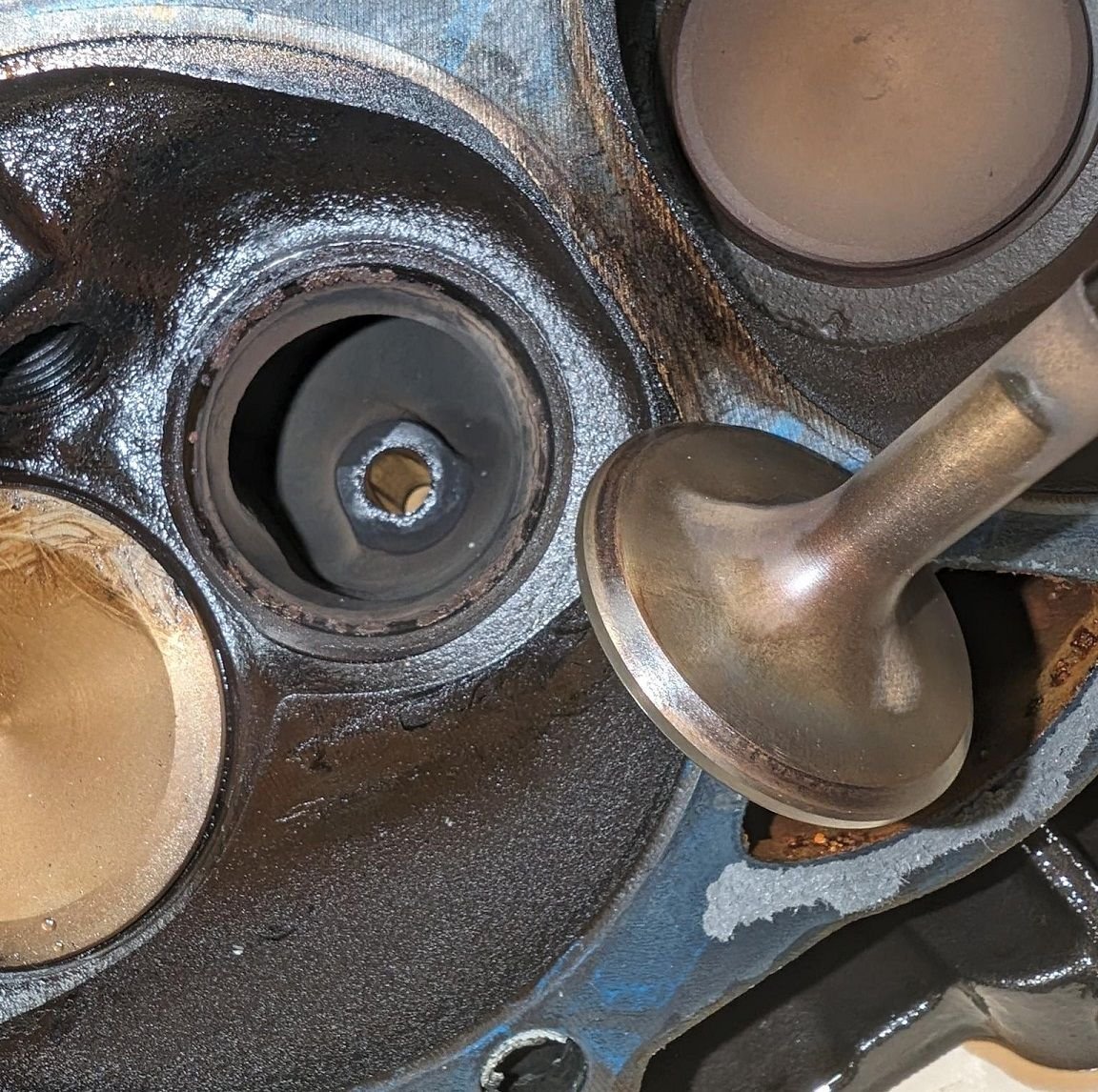

Pulled the port intake and #4 rockers so I could get the exhaust lifter out. Had to pull the guts to get a good grab of it (not a good sign) to pull it out. The intake lifter came right out and looked good.

Intake off

#4 exhaust

#4 exhaust

Also had a slight wobble when spinning all the pushrods so they need to be replaced as well as cam and lifters. Will start looking at options for roller cam set ups.

Next move is to check why both #5 cylinders are low on compression. I'll start with doing a pressure / leakdown test and see if its through the ports, crankcase, or gasket / water jacket..... hopefully....

Intake off

#4 exhaust

#4 exhaust

Also had a slight wobble when spinning all the pushrods so they need to be replaced as well as cam and lifters. Will start looking at options for roller cam set ups.

Next move is to check why both #5 cylinders are low on compression. I'll start with doing a pressure / leakdown test and see if its through the ports, crankcase, or gasket / water jacket..... hopefully....

#9

Registered

Thread Starter

Performed a quick leak down test with rubber tipped air gun. Loosened up rockers on both #5's and immediately got air leak through both exhaust ports. Did port #4 and air was pushing into the crank case, just what I didn't want to hear. So I went ahead and pulled both port heads and #5 exh valve.

The valve didn't look bent when spun in the guide but it did look lopsided so I chucked it up in the lathe.

Spinning the valve, the seat was straight, but the valve head looked like it was bent at one time and then the seat reground to take it out. Either way, they are getting replaced.

Port #4 just looked ugly, almost if they either missed the hone job, or the cylinder was so bad they honed it a bit to clean up some and then slapped the piston in it. You can feel the roughness seen in the pictures.

Now to look at options moving forward. Would be nice to put a set of aluminum heads on. Will check with my local chevy guys on their opinions.

The current piston / head set up gave a 10.5:1 compression ratio according to PO and said don't run anything less than 93 octane. Our rec fuel is only 90 octane and the premium 93 has ethanol. I would like to get away from ethanol fuel incase I need to fuel up at a marina sometime. That means running an octain booster, cutting back on timing, or both, or total rebuild of the engine. Would like to hear your thoughts on running 10.5 compression.

Definitely need new cams so checking into options for roller cams, roller rockers etc.

The distributor looked like a nice billet unit with a points plate in it. I'm no ignition expert so starting to see what options I have here. The season up here is coming quick.

Thanks, H

The valve didn't look bent when spun in the guide but it did look lopsided so I chucked it up in the lathe.

Spinning the valve, the seat was straight, but the valve head looked like it was bent at one time and then the seat reground to take it out. Either way, they are getting replaced.

Port #4 just looked ugly, almost if they either missed the hone job, or the cylinder was so bad they honed it a bit to clean up some and then slapped the piston in it. You can feel the roughness seen in the pictures.

Now to look at options moving forward. Would be nice to put a set of aluminum heads on. Will check with my local chevy guys on their opinions.

The current piston / head set up gave a 10.5:1 compression ratio according to PO and said don't run anything less than 93 octane. Our rec fuel is only 90 octane and the premium 93 has ethanol. I would like to get away from ethanol fuel incase I need to fuel up at a marina sometime. That means running an octain booster, cutting back on timing, or both, or total rebuild of the engine. Would like to hear your thoughts on running 10.5 compression.

Definitely need new cams so checking into options for roller cams, roller rockers etc.

The distributor looked like a nice billet unit with a points plate in it. I'm no ignition expert so starting to see what options I have here. The season up here is coming quick.

Thanks, H

#10

Are you planning to pull these down and at the very least replace main, rod, and cam bearings considering the lifter material that circulated through the engines? With stock Merc exhaust the largest roller cam profile you could get away and avoid reversion issues with is a very common 218/[email protected]" on a 112LSA. My preference is Howards Cams (111145-12), but Comp, Lunati, and others have a similar grind. Even with that cam profile and aluminum heads your pushing too far with 10.5:1 static compression and 90 octane. Been there, done that. 10.0:1 is safe with 91 that we have here in the midwest with that cam profile.

I'd do a thorough calculation of real static compression ratio (bore / stroke, piston dish cc's, piston depth in hole @ TDC, head gasket thickness and bore, and head chamber size) to see exactly where you are at. If your current heads are 64cc chambers maybe you can make 70 or 72cc chamber aluminum heads work. Otherwise once you're in that far build 383's with dished pistons of your choice to get the compression ratio and chamber quench perfect. Let us know what you come up with and we can provide advice from there.

I'd do a thorough calculation of real static compression ratio (bore / stroke, piston dish cc's, piston depth in hole @ TDC, head gasket thickness and bore, and head chamber size) to see exactly where you are at. If your current heads are 64cc chambers maybe you can make 70 or 72cc chamber aluminum heads work. Otherwise once you're in that far build 383's with dished pistons of your choice to get the compression ratio and chamber quench perfect. Let us know what you come up with and we can provide advice from there.