Hole removal

#11

Registered

That resin is just fine. I made almost the same repair with the exact shopping list at Home Depot a month ago. The guy that did my transom cut my drain plug hole too big and I had to fill it and drill it out smaller. The Bondo brand is just polyester and will work fine for the repair.

#12

Registered

Thread Starter

Yeah, basically it dripped out on one eng and a VERY fine stream on the other eng. This was starting with warm oil. By the time it finished, the oil was cold. Tried connecting to a 5 gal solvent can and applied a vac. Looked promising until the can collapsed making a really loud POW sound. Can was never the same afterwards. Eventually came up with a seriously red-neck solution that gets 7+ qts of warm oil out in 60 secs.

#13

Registered

Thread Starter

That resin is just fine. I made almost the same repair with the exact shopping list at Home Depot a month ago. The guy that did my transom cut my drain plug hole too big and I had to fill it and drill it out smaller. The Bondo brand is just polyester and will work fine for the repair.

Still not sure If I need to cut a small round section of glass cloth to place in the hole on top of the dowel. Is this to help keep the resin in the hole, add strength, provide for better gelcoat adhesion or a combination of the above? Is there a generally accepted limit on how big the hole needs to be before this is necessary?

#14

Registered

1 stop shopping. https://www.homedepot.com/p/HDX-1-qt...-2M3/202264024

I drilled my hole to 1-1/4". Hole was just over 1". I put a piece of gorilla tape over the hole on the back of the transom. I mixed up resin with West Systems 406 filler into a mayonnaise consistency. I filled the hole from the inside of bilge and squeezed out resin as I pushed the dowel in. I let it cure, removed tape, sanded smooth, painted, drilled hole, resin'd inside of hole and then installed my bilge drain. You can skip the last 3 steps.

I drilled my hole to 1-1/4". Hole was just over 1". I put a piece of gorilla tape over the hole on the back of the transom. I mixed up resin with West Systems 406 filler into a mayonnaise consistency. I filled the hole from the inside of bilge and squeezed out resin as I pushed the dowel in. I let it cure, removed tape, sanded smooth, painted, drilled hole, resin'd inside of hole and then installed my bilge drain. You can skip the last 3 steps.

The following users liked this post:

zz28zz (05-04-2021)

#15

Registered

Thread Starter

I asked the HD rep if they had mixing cups and he said no. Maybe at another store..

Thx for the guidance on the filler. Checked out the West Systems site. Lots of good info there. I'll be placing my order tonight. New starter bolts arrived today, so eng should be ready to re-install as soon as I can verify the starter is happy.

What's a good source for gelcoat? Is there more than one type?

Thx for the guidance on the filler. Checked out the West Systems site. Lots of good info there. I'll be placing my order tonight. New starter bolts arrived today, so eng should be ready to re-install as soon as I can verify the starter is happy.

What's a good source for gelcoat? Is there more than one type?

#16

Registered

The following users liked this post:

zz28zz (05-04-2021)

#17

Registered

Thread Starter

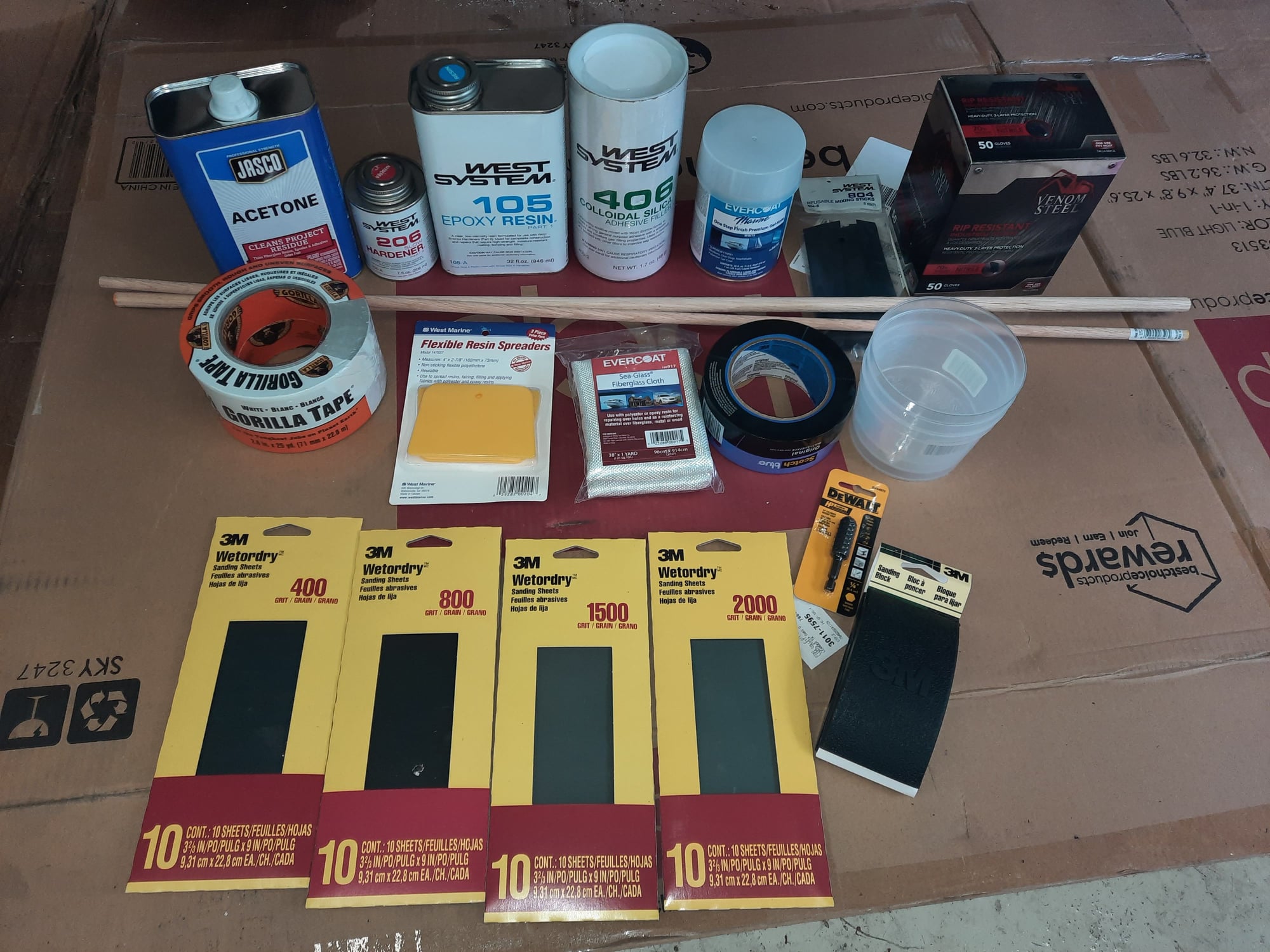

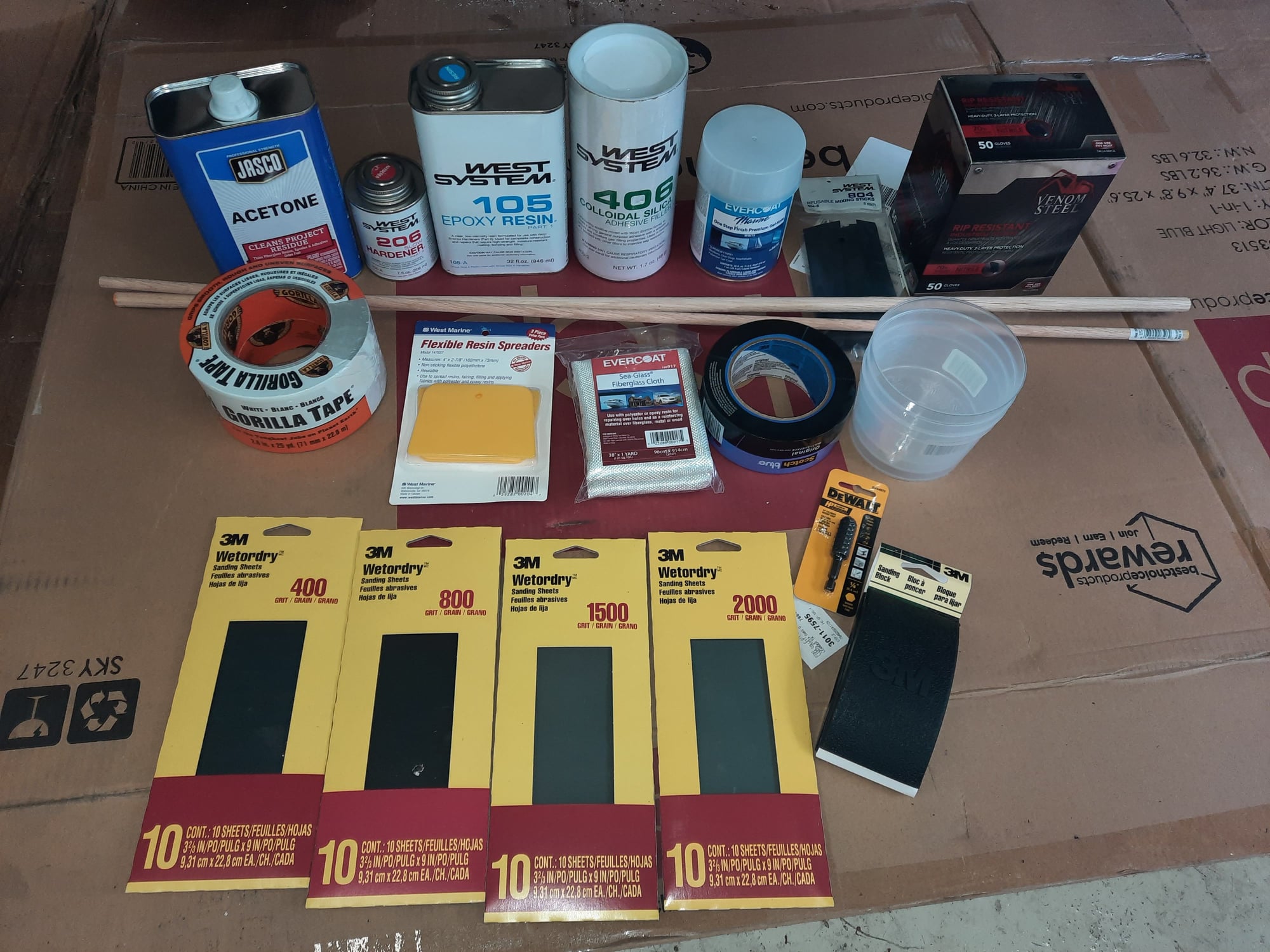

Had to visit West marine to get the 406 filler so picked-up the resin/hardener and few other misc items while I was there. Found the wet dry sandpaper at Home Depot. Hopefully I'm ready for the big day tomorrow and I didn't forget some key item.

#18

Registered

Thread Starter

Old oil drain line holes are plugged. Also had 4 un-used clamps on transom between drives. May have been for original speedo hose?? Anyway, those holes have also been filled too. Went pretty smooth except first resin mix cooked-off in 8 mins. Melted my plastic stir stick. It was supposed to have 20 min pot life. By the time I got the 406 filler mixed-in, it was starting to get warm. Got the wooden plugs installed with only abt 30 secs to spare. Had to make a second batch for the 4 small holes. Only used abt 1/2 of the hardner on second batch and that seems to have worked out abt right.

Shop was at 90 degs today, so I'm assuming that's probably why.. Gelcoat next weekend. Thx for the help guys.

Shop was at 90 degs today, so I'm assuming that's probably why.. Gelcoat next weekend. Thx for the help guys.

#19

*

Ambient temps can definitely affect the time it takes for the resin to fire off and it can be an unexpectedly expensive learning curve in the beginning. If it was 90f when you were doing the work that explains a lot.

Some of the resin manufacturers offer 'slow' 'normal' and 'fast' curing hardeners . When I was doing my stuff with it a few years back I ended up switching to the slow hardener and even then it could surprise me. I found it best to keep the mixes small when possible and definitely use plastic mixing pots and wooden stirrers.

If you ever have to play with the 2 part foam mixes and it's a 'warm' day , watch out !

Some of the resin manufacturers offer 'slow' 'normal' and 'fast' curing hardeners . When I was doing my stuff with it a few years back I ended up switching to the slow hardener and even then it could surprise me. I found it best to keep the mixes small when possible and definitely use plastic mixing pots and wooden stirrers.

If you ever have to play with the 2 part foam mixes and it's a 'warm' day , watch out !

#20

Registered

Thread Starter

It was 90 degs outside, so probably a little warmer in the shop. Directions said mix 5:1. First batch was 5 oz resin and 1 oz of the slow harder pictured. Second batch was 2.5 oz resin and 1/4 oz hardner.

Thought plastic mixing cup was going to melt with the first batch but it didn't.

I timed everything. 1.5 mins to mix resin and hardner and 5 1/2 min mixing in filler. Mixing could have gone a lot quicker but I had no clue how much it would take to achieve "mayonnaise" consistency. Next time I'll be mixing up a "test batch" first...

Thought plastic mixing cup was going to melt with the first batch but it didn't.

I timed everything. 1.5 mins to mix resin and hardner and 5 1/2 min mixing in filler. Mixing could have gone a lot quicker but I had no clue how much it would take to achieve "mayonnaise" consistency. Next time I'll be mixing up a "test batch" first...