Hole removal

#1

Registered

Thread Starter

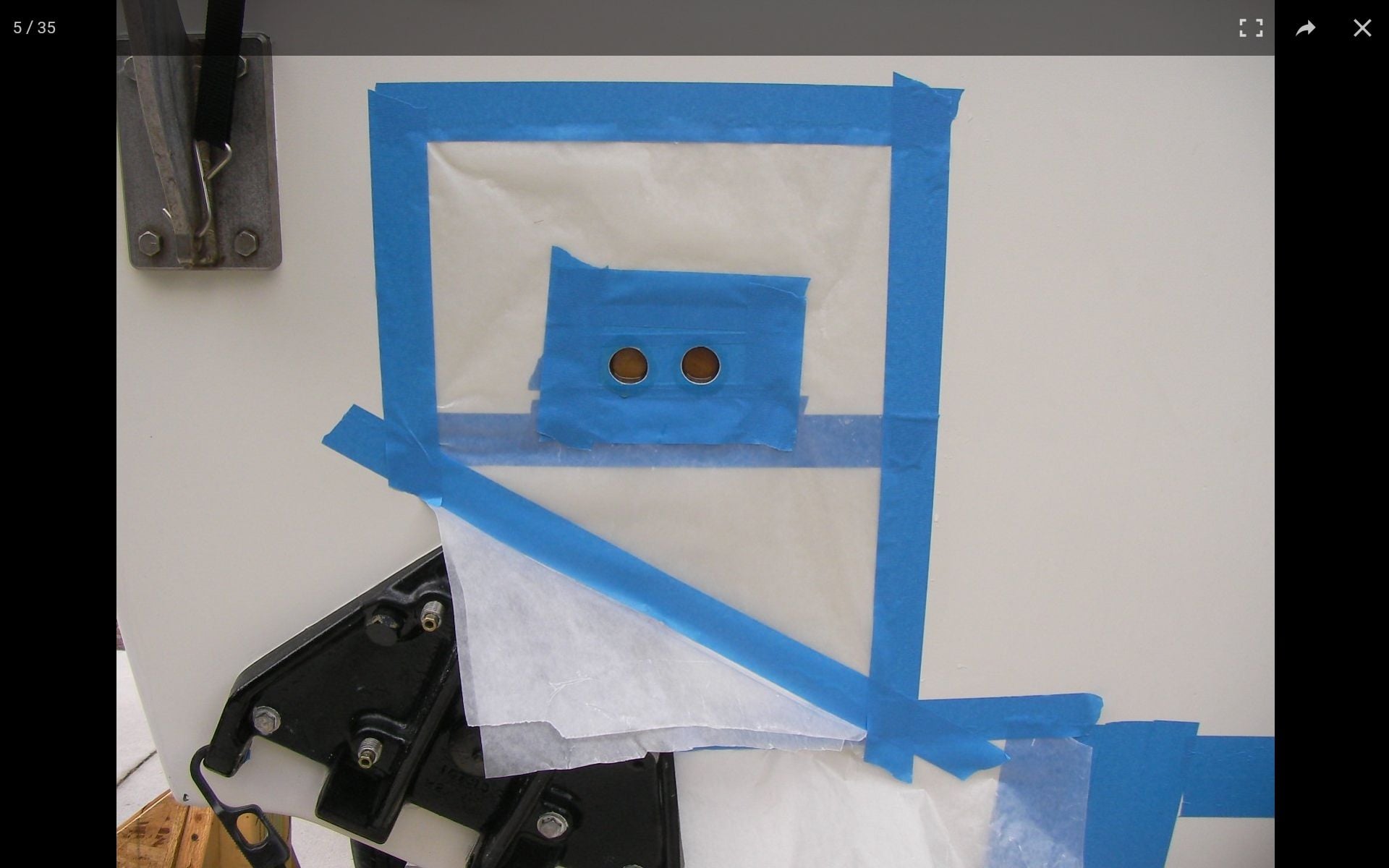

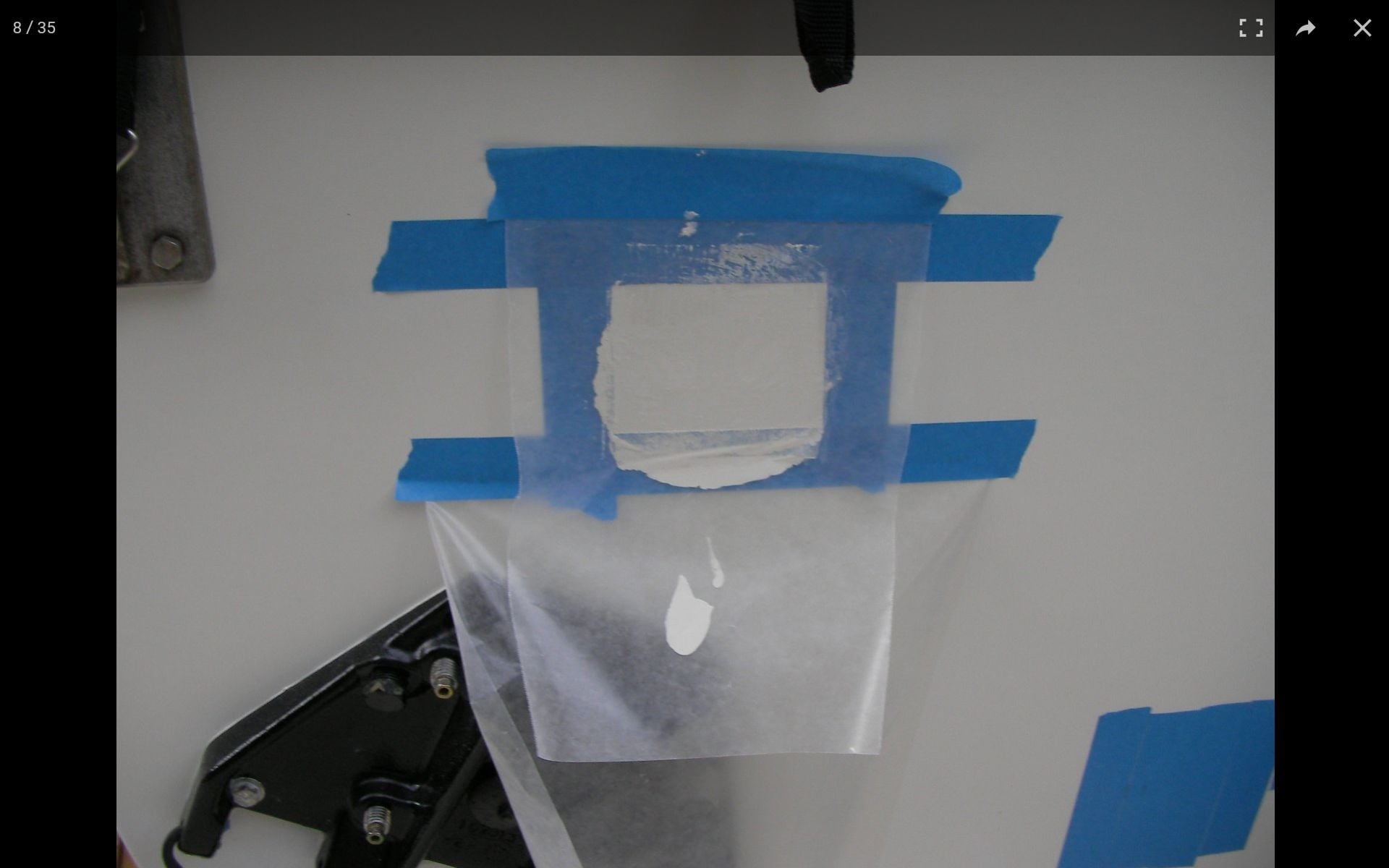

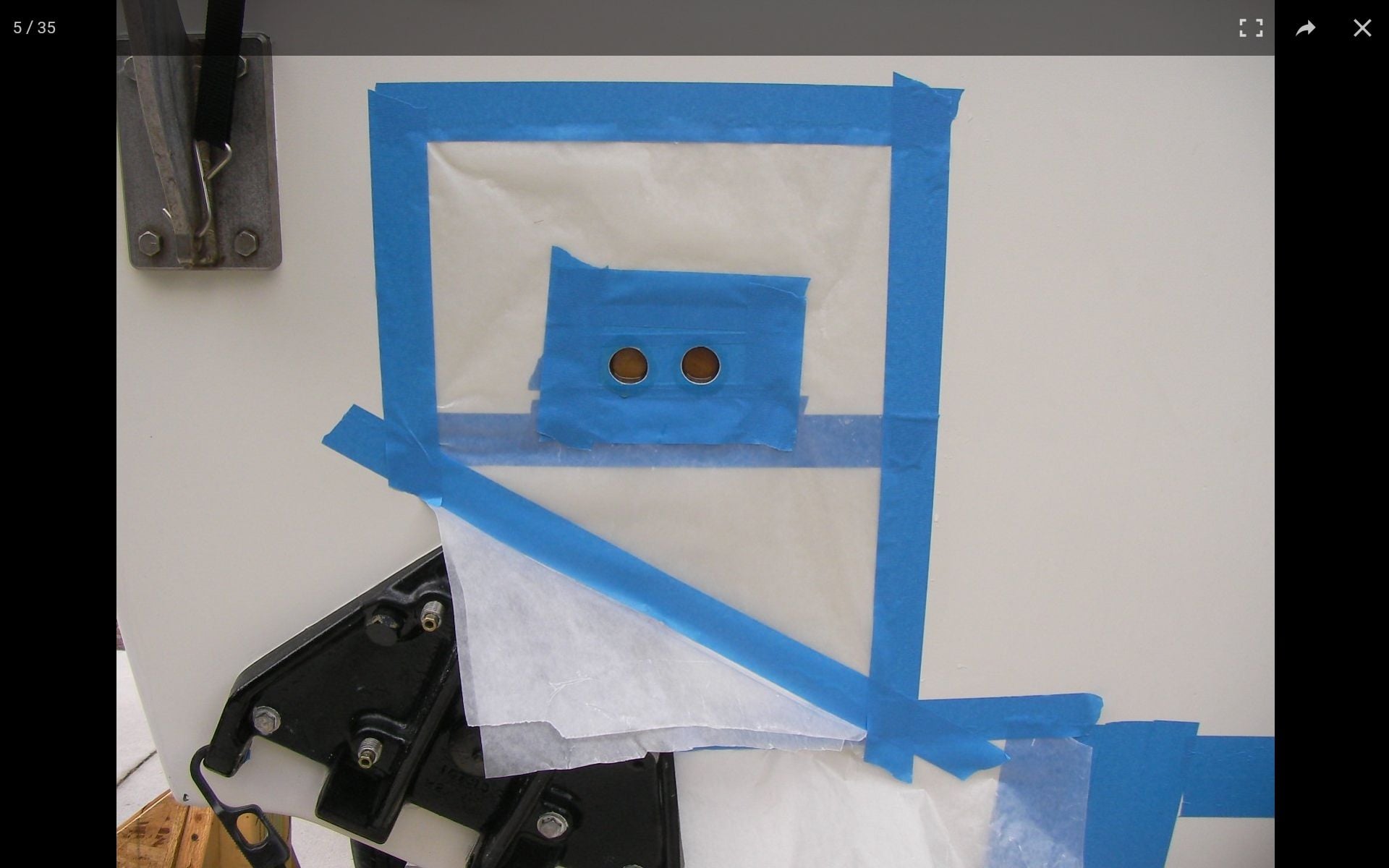

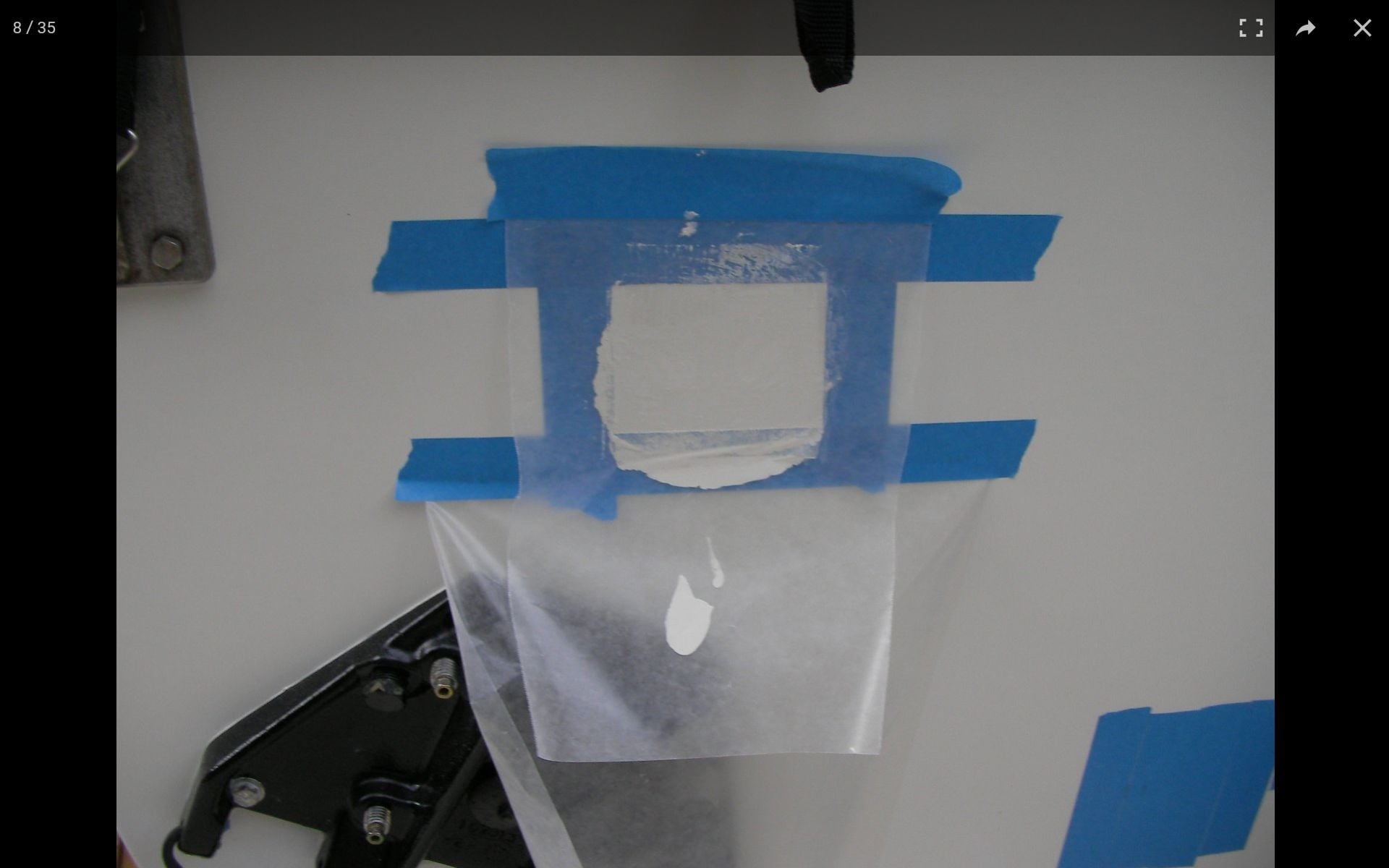

Prev owner installed custom eng oil drains that exited the bilge thru 2 holes drilled abt 3" left/right and above the drain plug. It never worked well and since I have an eng out, I'm wanting to remove the holes. I've been thru a similar procedure once when I installed ext steering. However this time I want to apply gelcoat after epoxy dries to really make the holes disappear. When filling the hole with epoxy, should I bring the epoxy all the way out to the surface (then sand) or stop a little short to allow room for gelcoat? How thick should the gelcoat be over the old hole? This will be my first experience applying gelcoat.

I used West Systems six10 epoxy last time. It had a mixer nozzle on the end of tube. Worked very well. Is there something better I could use?

Thx!

I used West Systems six10 epoxy last time. It had a mixer nozzle on the end of tube. Worked very well. Is there something better I could use?

Thx!

#2

Registered

filling holes

how to fill dash holes

Filling holes

read up on the subject, read some more, get your materials all sorted out, prep the holes really really good.

Cut your dowels 1/2 inch shorter than total thickness and have a smaller dowel marked at 1/4 inch to drive dowels into position so both sides can get glass. Did mine this way and they have held up with no issues.

how to fill dash holes

Filling holes

read up on the subject, read some more, get your materials all sorted out, prep the holes really really good.

Cut your dowels 1/2 inch shorter than total thickness and have a smaller dowel marked at 1/4 inch to drive dowels into position so both sides can get glass. Did mine this way and they have held up with no issues.

Last edited by outonsafari; 04-24-2021 at 07:46 AM.

The following users liked this post:

hblair (04-25-2021)

#3

Registered

Thread Starter

Got the old hardware out leaving holes abt 7/16" in diameter. Ran a 1/2" drill bit thru the holes and hit good clean wood.

I like the dowel pin idea and I know pine is out. Any recommendations on type of hardwood or would fiberglass dowels better?

I like the dowel pin idea and I know pine is out. Any recommendations on type of hardwood or would fiberglass dowels better?

#5

Registered

Thread Starter

I'm a newbie when it comes to glass work. I usually farm out any glass (or body work on cars) to the pros.. Never used either resin before. What little work I have done with glass I used epoxy. Seems there are about 1/2 dozen ways to skin a cat, but I'm just wanting to use whatever method will protect the transom best and look good.

#6

Registered

I was using West Systems also, but found with some glass mats that it really didn't wet out too good. (I believe 1708) The glue that bonds the 2 mats breaks down when using polyester or vinylester and allows the glass to get saturated. With the West System it didn't, seemed to leave a barrier. I don't believe the glass was ever fully saturated and was seemed weaker. I never had the gelcoat adhesion problems others mention when using epoxy. Just some info I wanted to pass along.

#7

Registered

Thread Starter

Good to know abt the wetting properties.

Which type resin would work best for this repair?

Do I need to place glass in the hole like is shown above? It's only a 1/2" hole but I believe I'm supposed to grind away a little more on the outside to remove any tiny cracks in existing gelcoat from drilling.

Which type resin would work best for this repair?

Do I need to place glass in the hole like is shown above? It's only a 1/2" hole but I believe I'm supposed to grind away a little more on the outside to remove any tiny cracks in existing gelcoat from drilling.

#9

Registered

Thread Starter

The oil drain fittings have been bugging me ever since I got the boat. They didn't really work. Took abt 24 hrs to drain the pan.

Picked up up some oak dowel today at home depot. They sell resin made by Bondo. Wasn't sure if that was the best choice or not so I passed. Tried finding a place that sells fiberglass repair supplies but no luck finding anything local that's still open. Called around looking for someone to come out to my place to do the repair, but no luck there either. The epoxy method is looking better and better.

Picked up up some oak dowel today at home depot. They sell resin made by Bondo. Wasn't sure if that was the best choice or not so I passed. Tried finding a place that sells fiberglass repair supplies but no luck finding anything local that's still open. Called around looking for someone to come out to my place to do the repair, but no luck there either. The epoxy method is looking better and better.

Last edited by zz28zz; 05-02-2021 at 01:59 AM.

#10

Registered

The oil drain fittings have been bugging me ever since I got the boat. They didn't really work. Took abt 24 hrs to drain the pan.

Picked up up some oak dowel today at home depot. They sell resin made by Bondo. Wasn't sure if that was the best choice or not so I passed. Tried finding a place that sells fiberglass repair supplies but no luck finding anything local that's still open. Called around looking for someone to come out to my place to do the repair, but no luck there either. The epoxy method is looking better and better.

Picked up up some oak dowel today at home depot. They sell resin made by Bondo. Wasn't sure if that was the best choice or not so I passed. Tried finding a place that sells fiberglass repair supplies but no luck finding anything local that's still open. Called around looking for someone to come out to my place to do the repair, but no luck there either. The epoxy method is looking better and better.

Wow that's a long time for gravity drain, thought my West Marine vacuum took long at 1.5 hrs.

Most leave the hoses laying in the bilge then feed each out of the bilge drain hole when needed.

Most leave the hoses laying in the bilge then feed each out of the bilge drain hole when needed.