Don't skip a year - TEST THOSE HEADERS

#31

Registered

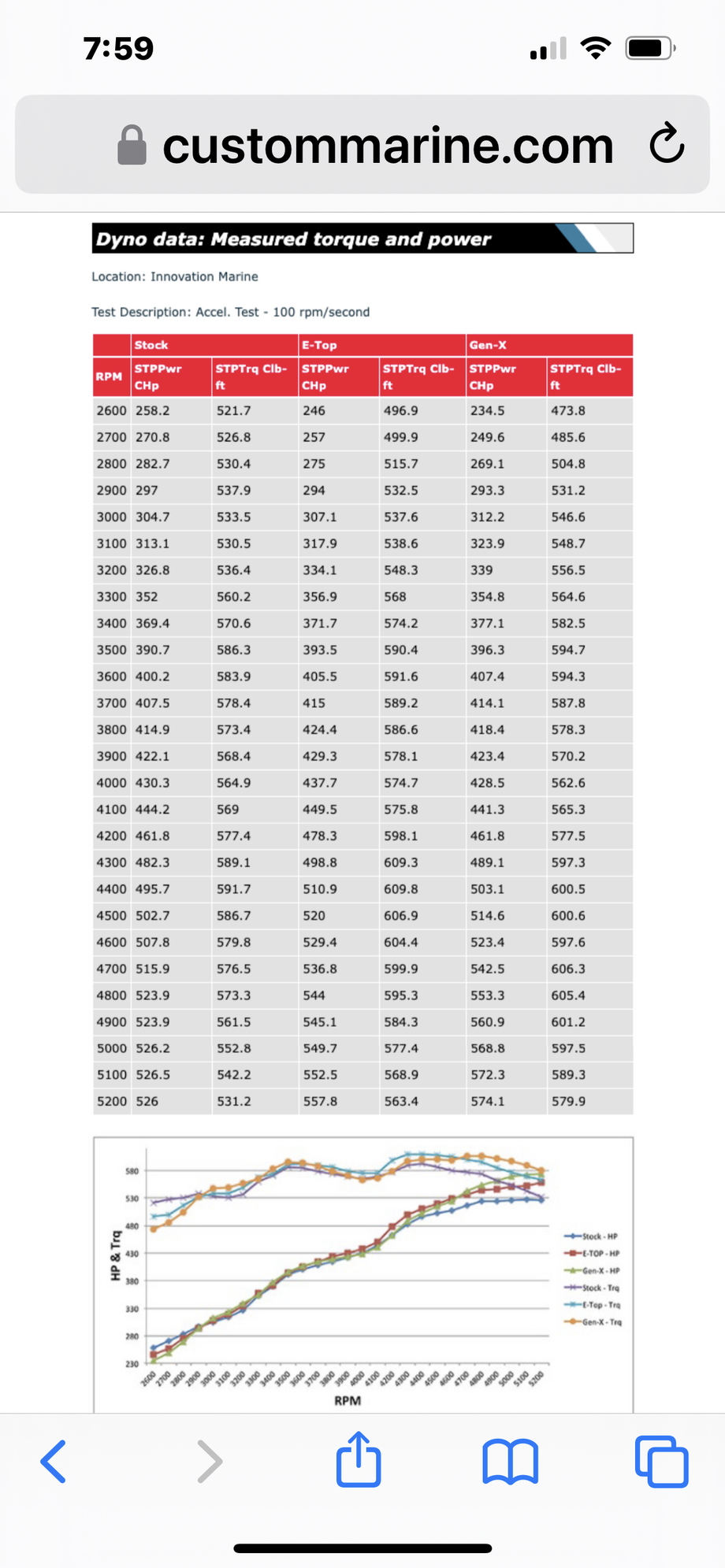

The 520 and 525 are similar. The 520 manifolds are the same as the 496 manifolds, and similar in size and shape to a stainless marine gen 2. If a 520 can gain 48hp in the upper rpm a 525 can lose at least 20-30

The following users liked this post:

SB (02-15-2023)

#32

Registered

Many years with small motorcycle motors and exhaust was everything.

The following users liked this post:

Unlimited jd (02-15-2023)

#33

Registered

I would love to see how it was set up on the dyno.

The following users liked this post:

Unlimited jd (02-15-2023)

#34

Registered

Me too, I was ready to buy all new stainless marine or Hardin exhaust at half the price. When I found this sheet I sucked it up and bought new cmi headers. My boat runs 91-92 most days, not willing to drop onto the 80’s over 5-10k. Most on here would spend that to gain 3-5 mph. Why save it to give it up.

#35

#36

The following users liked this post:

Wildman_grafix (02-17-2023)

#38

Registered

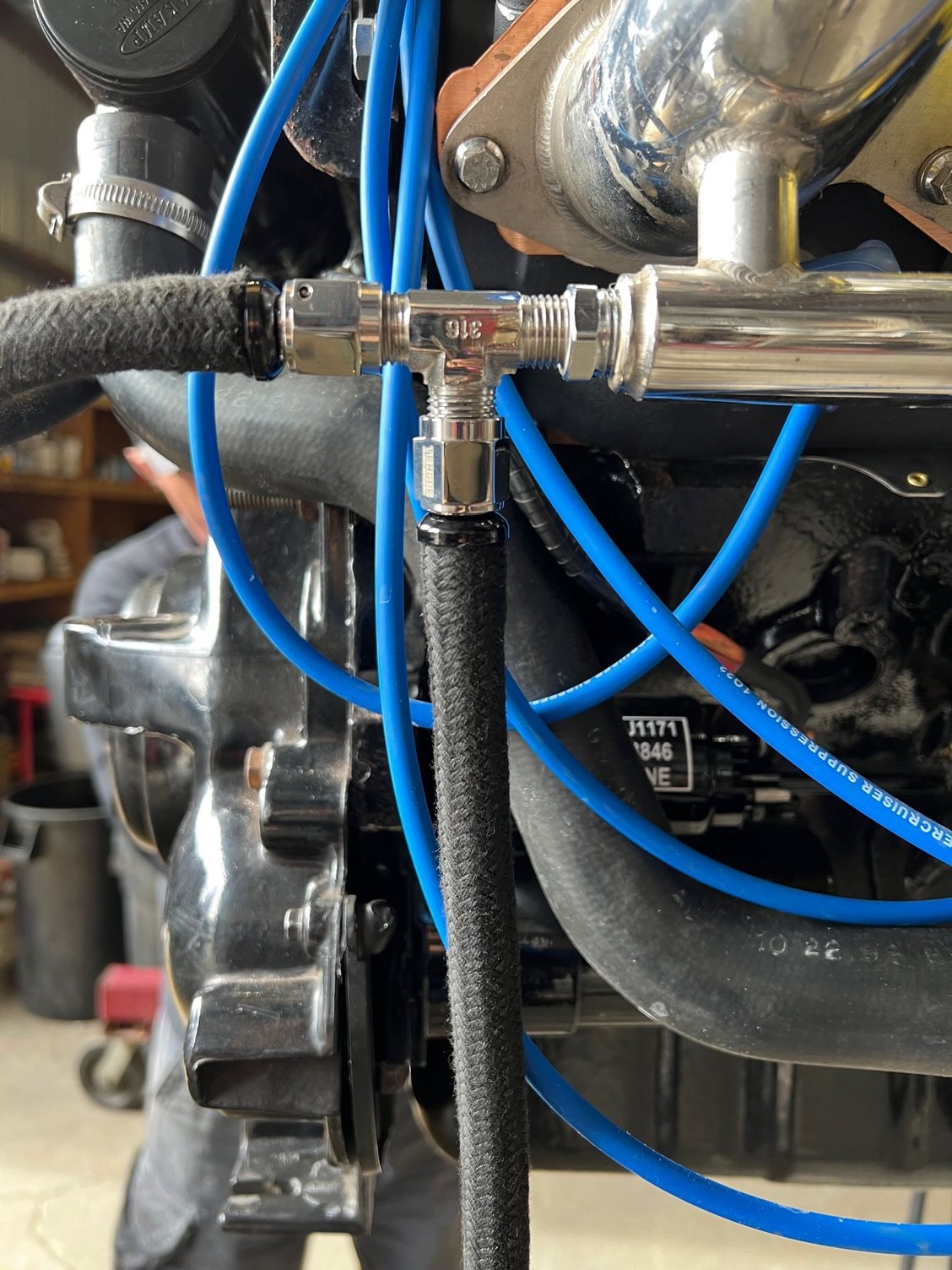

I’ve done it with compressed air, regulator with air line fitting, then a header to tail pipe jumper cut in half on other end of regulator. Attach that to either the water in at the rail or out at the collector. Cap which ever one you don’t use. A rubber barstool foot with a hose clamp works fine as a cap. Apply air and watch the regulator and listen.

The following users liked this post:

neva satisfied (02-17-2023)

#39

BEACH PARTY

That’ll get you lost of the way there but it’s also recommended that you test with a heat source. You’ll have to pull the headers to do that, but then you’ll know for sure.

I have a large tank that I dump my etops into. They’re connected to air and a gauge. I use the rubber distribution tube and a rubber cap on the jumper. Pressurized to 35-40 lbs and in they go. I watch for bubbles and a drop in pressure. Once that test is good, I pull them and then apply heat via a propane torch to the flange welds where the pipes come into the collector.

The headers are twenty-two years old and no leaks so far. When the engines went back in this time, I added ball valves to drain them into the bilge. I sleep much easier now.

I have a large tank that I dump my etops into. They’re connected to air and a gauge. I use the rubber distribution tube and a rubber cap on the jumper. Pressurized to 35-40 lbs and in they go. I watch for bubbles and a drop in pressure. Once that test is good, I pull them and then apply heat via a propane torch to the flange welds where the pipes come into the collector.

The headers are twenty-two years old and no leaks so far. When the engines went back in this time, I added ball valves to drain them into the bilge. I sleep much easier now.

#40

Registered

That’ll get you lost of the way there but it’s also recommended that you test with a heat source. You’ll have to pull the headers to do that, but then you’ll know for sure.

I have a large tank that I dump my etops into. They’re connected to air and a gauge. I use the rubber distribution tube and a rubber cap on the jumper. Pressurized to 35-40 lbs and in they go. I watch for bubbles and a drop in pressure. Once that test is good, I pull them and then apply heat via a propane torch to the flange welds where the pipes come into the collector.

The headers are twenty-two years old and no leaks so far. When the engines went back in this time, I added ball valves to drain them into the bilge. I sleep much easier now.

I have a large tank that I dump my etops into. They’re connected to air and a gauge. I use the rubber distribution tube and a rubber cap on the jumper. Pressurized to 35-40 lbs and in they go. I watch for bubbles and a drop in pressure. Once that test is good, I pull them and then apply heat via a propane torch to the flange welds where the pipes come into the collector.

The headers are twenty-two years old and no leaks so far. When the engines went back in this time, I added ball valves to drain them into the bilge. I sleep much easier now.