Baffled by apparent reversion issues with Lightning headers and mild cam

#103

Since I was able to fix the plug threads, I ran it again, hoping the silicone in the joint would solve my water issues. No such luck.

Collector high and dry before running:

This is what I had after running it at at 1500 RPM idle for maybe 45 seconds. Obviously very wet in there all the way back to the primaries. Sorry the pic is not so clear - still a lot of mist in there.

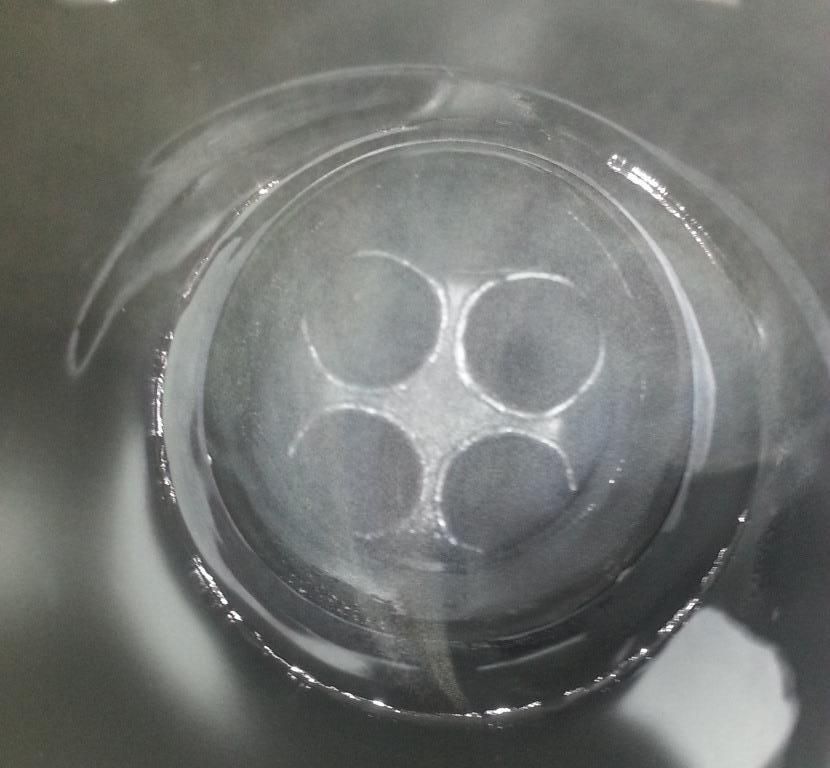

So just out of curiosity, I took US1 Fountain's advice and hooked water directly to the log for the header and ran water out the pipe without the engine running. Damn thing looked like Niagara Falls.

I seriously think this is a lot of the problem here. Even with no exhaust pulses back on it, there was significant water splashing back up the pipe. There is also about a 5/16 hole at the bottom that would probably put out enough water by itself to cool the tip and hose. Look at this thing pizzing water with almost no pressure on it.

So I think the only way to solve this problem is to either weld in something to reflect the water back towards the tips, or perhaps even close off some or all of the upper holes. I am concerned that I may build up too much pressure in the block if I do this without installing dumps somewhere, either on the collectors or further upstream. Right now all of the water that goes through the engine exits here.

So the saga continues. Oh yeah, even starting to see a little bit of rust around my exhaust valves.

After seeing this, do you guys still think I should just drop the engine in the boat and run it like this?

Collector high and dry before running:

This is what I had after running it at at 1500 RPM idle for maybe 45 seconds. Obviously very wet in there all the way back to the primaries. Sorry the pic is not so clear - still a lot of mist in there.

So just out of curiosity, I took US1 Fountain's advice and hooked water directly to the log for the header and ran water out the pipe without the engine running. Damn thing looked like Niagara Falls.

I seriously think this is a lot of the problem here. Even with no exhaust pulses back on it, there was significant water splashing back up the pipe. There is also about a 5/16 hole at the bottom that would probably put out enough water by itself to cool the tip and hose. Look at this thing pizzing water with almost no pressure on it.

So I think the only way to solve this problem is to either weld in something to reflect the water back towards the tips, or perhaps even close off some or all of the upper holes. I am concerned that I may build up too much pressure in the block if I do this without installing dumps somewhere, either on the collectors or further upstream. Right now all of the water that goes through the engine exits here.

So the saga continues. Oh yeah, even starting to see a little bit of rust around my exhaust valves.

After seeing this, do you guys still think I should just drop the engine in the boat and run it like this?

#104

Fast Singles Club

Since I was able to fix the plug threads, I ran it again, hoping the silicone in the joint would solve my water issues. No such luck.

Collector high and dry before running:

This is what I had after running it at at 1500 RPM idle for maybe 45 seconds. Obviously very wet in there all the way back to the primaries. Sorry the pic is not so clear - still a lot of mist in there.

So just out of curiosity, I took US1 Fountain's advice and hooked water directly to the log for the header and ran water out the pipe without the engine running. Damn thing looked like Niagara Falls.

I seriously think this is a lot of the problem here. Even with no exhaust pulses back on it, there was significant water splashing back up the pipe. There is also about a 5/16 hole at the bottom that would probably put out enough water by itself to cool the tip and hose. Look at this thing pizzing water with almost no pressure on it.

So I think the only way to solve this problem is to either weld in something to reflect the water back towards the tips, or perhaps even close off some or all of the upper holes. I am concerned that I may build up too much pressure in the block if I do this without installing dumps somewhere, either on the collectors or further upstream. Right now all of the water that goes through the engine exits here.

So the saga continues. Oh yeah, even starting to see a little bit of rust around my exhaust valves.

After seeing this, do you guys still think I should just drop the engine in the boat and run it like this?

Collector high and dry before running:

This is what I had after running it at at 1500 RPM idle for maybe 45 seconds. Obviously very wet in there all the way back to the primaries. Sorry the pic is not so clear - still a lot of mist in there.

So just out of curiosity, I took US1 Fountain's advice and hooked water directly to the log for the header and ran water out the pipe without the engine running. Damn thing looked like Niagara Falls.

I seriously think this is a lot of the problem here. Even with no exhaust pulses back on it, there was significant water splashing back up the pipe. There is also about a 5/16 hole at the bottom that would probably put out enough water by itself to cool the tip and hose. Look at this thing pizzing water with almost no pressure on it.

So I think the only way to solve this problem is to either weld in something to reflect the water back towards the tips, or perhaps even close off some or all of the upper holes. I am concerned that I may build up too much pressure in the block if I do this without installing dumps somewhere, either on the collectors or further upstream. Right now all of the water that goes through the engine exits here.

So the saga continues. Oh yeah, even starting to see a little bit of rust around my exhaust valves.

After seeing this, do you guys still think I should just drop the engine in the boat and run it like this?

#105

Registered

Have I mentioned that set up sucks, yet ? LOL.

#106

Registered

im starting to think you should never install the engine in the boat.maybe it should be used as an anchor.be very careful putting water through the header with the engine not running,you need the exhaust pressure to blow the water out of the pipe.ps,just kidding about the boat anchor.

#108

Registered

Budman, don't worry. We'll get it fixed. I'll hit you up on the other site with my # and we'll talk. We'll figure out best and cheapest way to get it done. I have ideas, just need s little one on one for more info on the boat set up itself. AKA CFM

#109

Registered

chitcan your exhaust and buy a good used setup,probibaly cost about the same as a good set of clubs!

#110

Yeah, easy fix would be to go out and buy a set of Stainless Marine, Eickert, etc., but #1, I'm tapped out, and #2, I have that transom alignment issue with the exhaust holes. Had a set of Gils I was going to use a couple of years ago, but no way they would line up.

Sigh.

Anyone think of a way to temporarily shut off the upper holes to see if that would help and still keep the tips cool? Silicone?

Sigh.

Anyone think of a way to temporarily shut off the upper holes to see if that would help and still keep the tips cool? Silicone?