Cam question

#1

Registered

Thread Starter

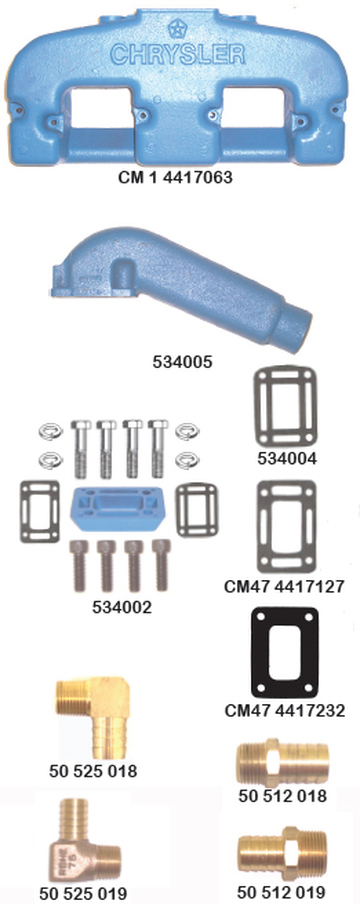

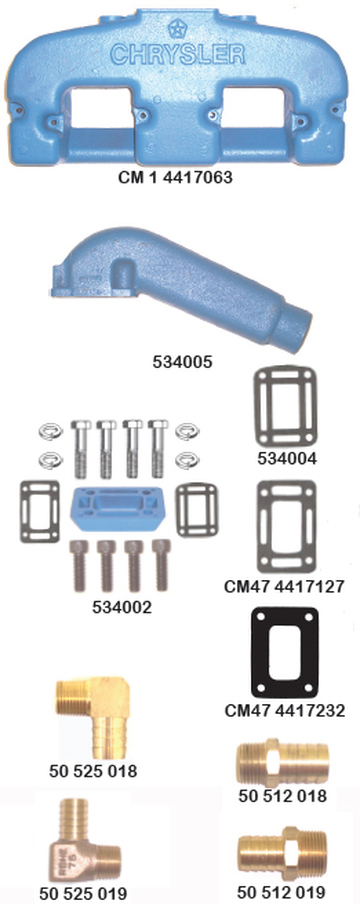

Let me start with, I know I am fighting an uphill battle running 2 small block chryslers in a boat, but I'm a die hard Mopar guy, and that is why I bought my particular 27' Magnum. I'm looking at these 2 grinds for cams on my 400" Small block Mopar engines. (4.030 Bore 4" stroke) 9.5 to 1 compression and ported aftermarket Iron heads with 2.02 and 1.62 Valves. For exhaust I'm using these manifolds: I may have some stainless risers modified or made for them if needed.

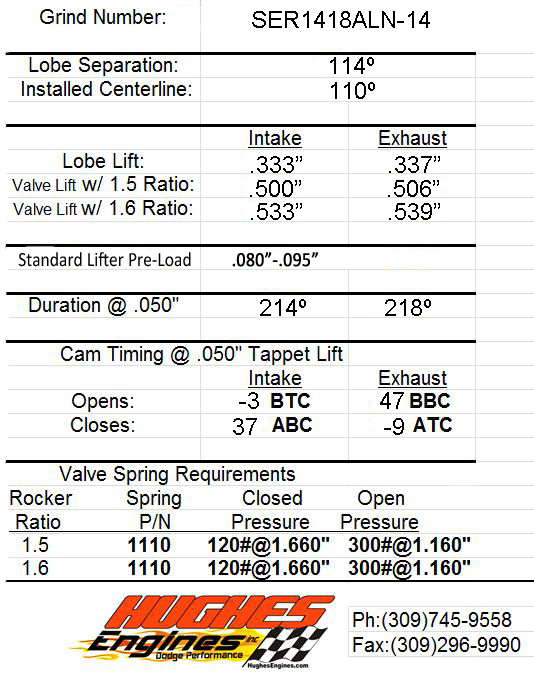

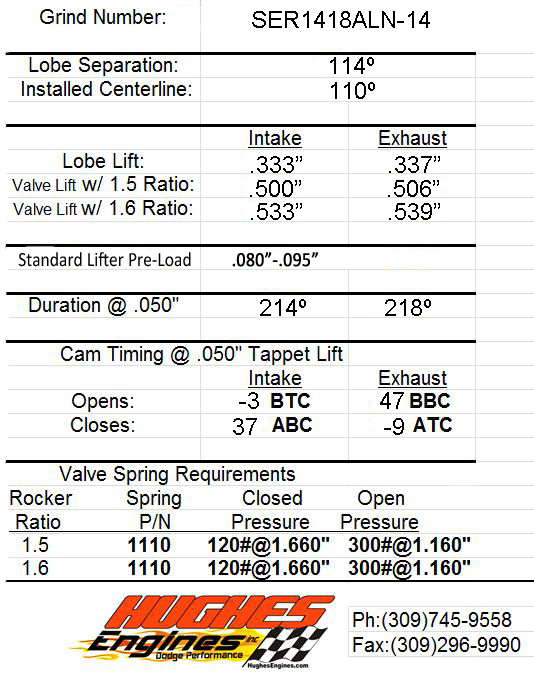

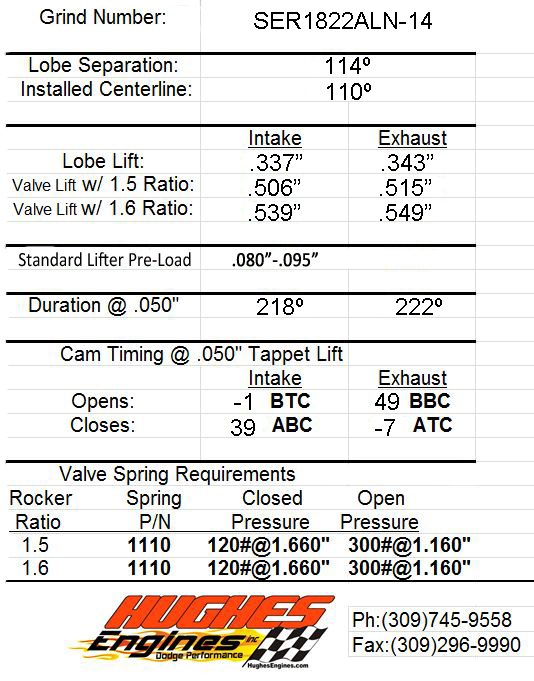

These are the cam specs:

Am I going to be ok reversion wise? The 114 degree seperation should give them a pretty smooth idle. I'm hoping for ~ 400HP each.

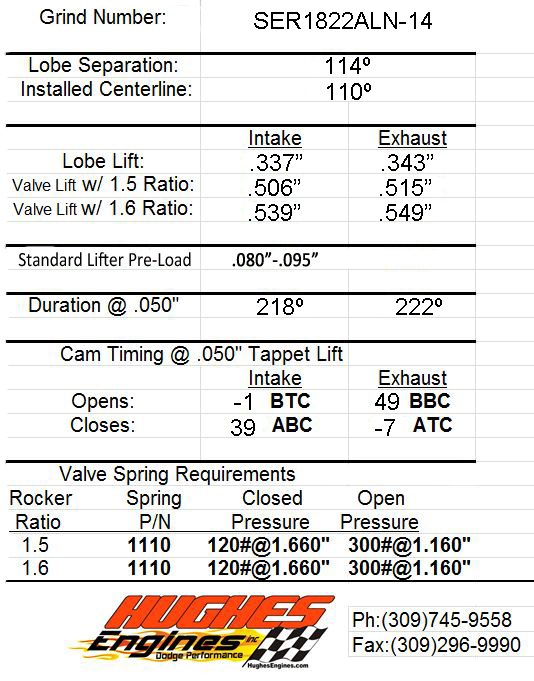

These are the cam specs:

Am I going to be ok reversion wise? The 114 degree seperation should give them a pretty smooth idle. I'm hoping for ~ 400HP each.

#4

Registered

This is what I did with mine. Sold the boat a couple years back and still hear how much they liked the motor.

*Edelbrock chrome air cleaner (with K and N filter)

*Edelbrock #1410 750cfm marine carburetor

*Prestolite marine distributor (totally rebuilt) also added a Pertronix

Igniter electronic ignition upgrade kit.

*Accel Super Stock coil

*Accel 8mm Hi performance wires

*Edelbrock Performer RPM air gap aluminum manifold

*Magnum swirl port cast iron heads with 1.88"/1.60" valves

3 angel valve ports

Crain PowerMax race valve springs

Performer retainers and seals

*Crower performance push rods. Specially cut for

+1.00 in length. (mopar valve trains are non adjustable, if you make

changes you have to compensate with longer pushrods. Most have to

be custom made).

*Edelbrock chrome valve covers

*Weiand marine action plus water pump

*Edelbrock,True double roller timing set

*Crain PowerMax cam shaft and lifters set (a very cool duel plain cam)

adv dur int/exh 278/290

dur @ .050 int/exh 222/234

lift int/exh .467/494

deg of lobe separation 114

*Federal Mogal bearings

Main, rod and cam

*Block

1985 Chrysler 360ci (vin # W)

dipped, fluxed and all surfaces honed.

cylinders were cut .30 over

*Sterling pistons

.30 over flat top with valve relief's

10.25 to 1 compression

*Hastings molly rings

Speed balanced

*OEM connecting rods

reconditioned

speed balanced

*OEM Crank

reconditioned and reground

mains .10 under

journals .20 under

speed balanced

*Melling high performance oil pump

with a molly oil pump shaft

*Flywheel

12.5" 318ci flywheel (very rare)

custom balanced for a 360ci

*Fel-pro and victor gaskets

*Brass freeze plugs

*Stainless steel bolt set

*Edelbrock chrome air cleaner (with K and N filter)

*Edelbrock #1410 750cfm marine carburetor

*Prestolite marine distributor (totally rebuilt) also added a Pertronix

Igniter electronic ignition upgrade kit.

*Accel Super Stock coil

*Accel 8mm Hi performance wires

*Edelbrock Performer RPM air gap aluminum manifold

*Magnum swirl port cast iron heads with 1.88"/1.60" valves

3 angel valve ports

Crain PowerMax race valve springs

Performer retainers and seals

*Crower performance push rods. Specially cut for

+1.00 in length. (mopar valve trains are non adjustable, if you make

changes you have to compensate with longer pushrods. Most have to

be custom made).

*Edelbrock chrome valve covers

*Weiand marine action plus water pump

*Edelbrock,True double roller timing set

*Crain PowerMax cam shaft and lifters set (a very cool duel plain cam)

adv dur int/exh 278/290

dur @ .050 int/exh 222/234

lift int/exh .467/494

deg of lobe separation 114

*Federal Mogal bearings

Main, rod and cam

*Block

1985 Chrysler 360ci (vin # W)

dipped, fluxed and all surfaces honed.

cylinders were cut .30 over

*Sterling pistons

.30 over flat top with valve relief's

10.25 to 1 compression

*Hastings molly rings

Speed balanced

*OEM connecting rods

reconditioned

speed balanced

*OEM Crank

reconditioned and reground

mains .10 under

journals .20 under

speed balanced

*Melling high performance oil pump

with a molly oil pump shaft

*Flywheel

12.5" 318ci flywheel (very rare)

custom balanced for a 360ci

*Fel-pro and victor gaskets

*Brass freeze plugs

*Stainless steel bolt set

#5

Registered

Thread Starter

These are the unported numbers for the heads

INTAKE EXHAUST

.100 59 54

.200 136 105

.300 192 139

.400 231 166

.500 251 181

and Ported #s

.100 68.4 62.3

.200 140.4 110.2

.300 205.1 176.0

.350 230.1 191.8

.400 251.5 200.7

.450 268.7 205.0

.500 277.4 211.1

.600 291.4 216.3

The intakes will be Edelbrock Performer RPM Air Gaps with 750 CFM Edelbrock carbs. Being a Mopar guy, I know my way around the Carter AFB carb pretty well. As for ignition It will be DUI modified GM HEI distributors for the Mopar application. Looking to prop the motors to get them to 5500 RPM or so. Running Volvo SP-A drives (The last of the Aquamatic series, so I dont want to spin them too high.

INTAKE EXHAUST

.100 59 54

.200 136 105

.300 192 139

.400 231 166

.500 251 181

and Ported #s

.100 68.4 62.3

.200 140.4 110.2

.300 205.1 176.0

.350 230.1 191.8

.400 251.5 200.7

.450 268.7 205.0

.500 277.4 211.1

.600 291.4 216.3

The intakes will be Edelbrock Performer RPM Air Gaps with 750 CFM Edelbrock carbs. Being a Mopar guy, I know my way around the Carter AFB carb pretty well. As for ignition It will be DUI modified GM HEI distributors for the Mopar application. Looking to prop the motors to get them to 5500 RPM or so. Running Volvo SP-A drives (The last of the Aquamatic series, so I dont want to spin them too high.

#6

Registered

Thread Starter

This is what I did with mine. Sold the boat a couple years back and still hear how much they liked the motor.

*Edelbrock chrome air cleaner (with K and N filter)

*Edelbrock #1410 750cfm marine carburetor

*Prestolite marine distributor (totally rebuilt) also added a Pertronix

Igniter electronic ignition upgrade kit.

*Accel Super Stock coil

*Accel 8mm Hi performance wires

*Edelbrock Performer RPM air gap aluminum manifold

*Magnum swirl port cast iron heads with 1.88"/1.60" valves

3 angel valve ports

Crain PowerMax race valve springs

Performer retainers and seals

*Crower performance push rods. Specially cut for

+1.00 in length. (mopar valve trains are non adjustable, if you make

changes you have to compensate with longer pushrods. Most have to

be custom made).

*Edelbrock chrome valve covers

*Weiand marine action plus water pump

*Edelbrock,True double roller timing set

*Crain PowerMax cam shaft and lifters set (a very cool duel plain cam)

adv dur int/exh 278/290

dur @ .050 int/exh 222/234

lift int/exh .467/494

deg of lobe separation 114

*Federal Mogal bearings

Main, rod and cam

*Block

1985 Chrysler 360ci (vin # W)

dipped, fluxed and all surfaces honed.

cylinders were cut .30 over

*Sterling pistons

.30 over flat top with valve relief's

10.25 to 1 compression

*Hastings molly rings

Speed balanced

*OEM connecting rods

reconditioned

speed balanced

*OEM Crank

reconditioned and reground

mains .10 under

journals .20 under

speed balanced

*Melling high performance oil pump

with a molly oil pump shaft

*Flywheel

12.5" 318ci flywheel (very rare)

custom balanced for a 360ci

*Fel-pro and victor gaskets

*Brass freeze plugs

*Stainless steel bolt set

*Edelbrock chrome air cleaner (with K and N filter)

*Edelbrock #1410 750cfm marine carburetor

*Prestolite marine distributor (totally rebuilt) also added a Pertronix

Igniter electronic ignition upgrade kit.

*Accel Super Stock coil

*Accel 8mm Hi performance wires

*Edelbrock Performer RPM air gap aluminum manifold

*Magnum swirl port cast iron heads with 1.88"/1.60" valves

3 angel valve ports

Crain PowerMax race valve springs

Performer retainers and seals

*Crower performance push rods. Specially cut for

+1.00 in length. (mopar valve trains are non adjustable, if you make

changes you have to compensate with longer pushrods. Most have to

be custom made).

*Edelbrock chrome valve covers

*Weiand marine action plus water pump

*Edelbrock,True double roller timing set

*Crain PowerMax cam shaft and lifters set (a very cool duel plain cam)

adv dur int/exh 278/290

dur @ .050 int/exh 222/234

lift int/exh .467/494

deg of lobe separation 114

*Federal Mogal bearings

Main, rod and cam

*Block

1985 Chrysler 360ci (vin # W)

dipped, fluxed and all surfaces honed.

cylinders were cut .30 over

*Sterling pistons

.30 over flat top with valve relief's

10.25 to 1 compression

*Hastings molly rings

Speed balanced

*OEM connecting rods

reconditioned

speed balanced

*OEM Crank

reconditioned and reground

mains .10 under

journals .20 under

speed balanced

*Melling high performance oil pump

with a molly oil pump shaft

*Flywheel

12.5" 318ci flywheel (very rare)

custom balanced for a 360ci

*Fel-pro and victor gaskets

*Brass freeze plugs

*Stainless steel bolt set

The heads I'm running are made in Australia and are an updated Magnum head, like the ones you used. I am running the 92 and up Magnum block which is set up for hydraulic roller cams, hence the ability to get an extra .100 lift at a similar duration.

#7

Registered

Going by the pictures, the degree rate of fall of the risers looks good. I would say the larger 218/222 cam should be fine,

400hp shouldn't be an issue with those heads and cid.

Here's a decent artice on exhaust rate of fall, I have a Merc article somewhere in computer, but can't find i yet

https://www.perfprotech.com/blog/art...-riser-height#

edit in: above article shows minimum rate of fall. More rate of fall offers more protection.

f_inscreename - what did you use for exhaust, I ask so we can compare to the OP's.

Since this build is using wet exhaust, that will remove some of the worry of certain 'members' posting, if that is what you are getting at.

400hp shouldn't be an issue with those heads and cid.

Here's a decent artice on exhaust rate of fall, I have a Merc article somewhere in computer, but can't find i yet

https://www.perfprotech.com/blog/art...-riser-height#

edit in: above article shows minimum rate of fall. More rate of fall offers more protection.

f_inscreename - what did you use for exhaust, I ask so we can compare to the OP's.

Since this build is using wet exhaust, that will remove some of the worry of certain 'members' posting, if that is what you are getting at.

Last edited by SB; 11-20-2015 at 04:59 AM.

#8

Registered

#9

Registered

Let me start with, I know I am fighting an uphill battle running 2 small block chryslers in a boat, but I'm a die hard Mopar guy, and that is why I bought my particular 27' Magnum. I'm looking at these 2 grinds for cams on my 400" Small block Mopar engines. (4.030 Bore 4" stroke) 9.5 to 1 compression and ported aftermarket Iron heads with 2.02 and 1.62 Valves. For exhaust I'm using these manifolds: I may have some stainless risers modified or made for them if needed.

These are the cam specs:

Am I going to be ok reversion wise? The 114 degree seperation should give them a pretty smooth idle. I'm hoping for ~ 400HP each.

These are the cam specs:

Am I going to be ok reversion wise? The 114 degree seperation should give them a pretty smooth idle. I'm hoping for ~ 400HP each.

You have the volvo drives on that magnum or mercs?

#10

Registered

Thread Starter

Volvos. I swapped up to the SP-A drives which are the last of the AQ series (250,270,280,290). So they have the built in trim incorporated into the transom plate. I also raised the "X" 2"

I also know that f_inscreenname used HiTek water jacketed headers on his build but had some issues with them that is what is making me lean towards the later factory manifolds

I also know that f_inscreenname used HiTek water jacketed headers on his build but had some issues with them that is what is making me lean towards the later factory manifolds