Bore notching 454's

#11

I was even more aggressive than Jim V. was.

The first time I did it was on one of the old factory 454 blocks that had the square cut notch.

I just smoothed it out figuring that a smooth notch would be better than the square cut.

this was a LONG time ago before I had heard about bore notching.

I just did it because I TINKER with things.

The first time I did it was on one of the old factory 454 blocks that had the square cut notch.

I just smoothed it out figuring that a smooth notch would be better than the square cut.

this was a LONG time ago before I had heard about bore notching.

I just did it because I TINKER with things.

#13

Registered

I would add, will drop compression (add's volume to be compressed by piston) and only help upper R's.

I did it to my old 440/6 Super Bee and I took a bunch of meat out of the bores for it to be right.

I did it to my old 440/6 Super Bee and I took a bunch of meat out of the bores for it to be right.

#15

Registered

Thread Starter

#16

Registered

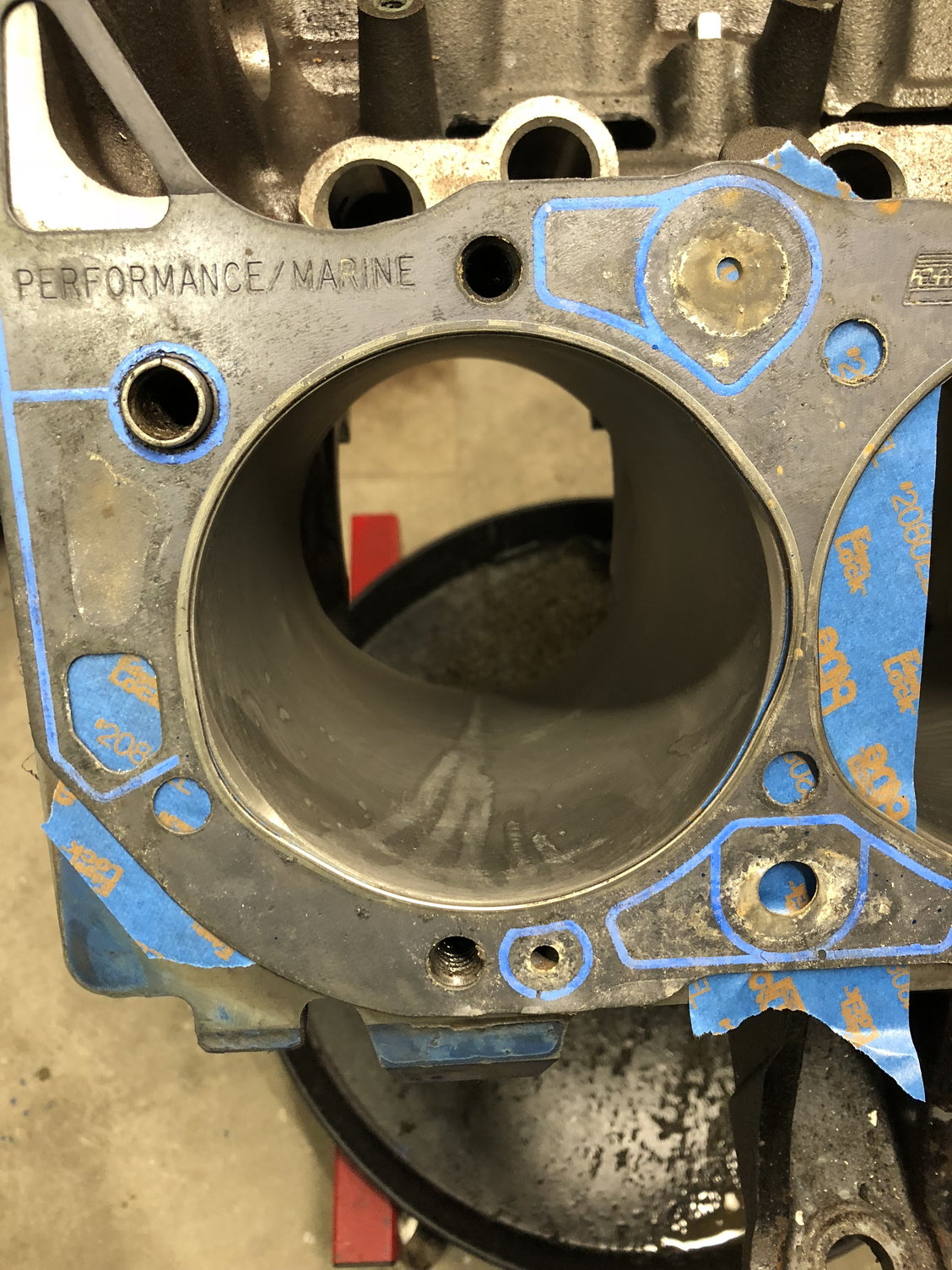

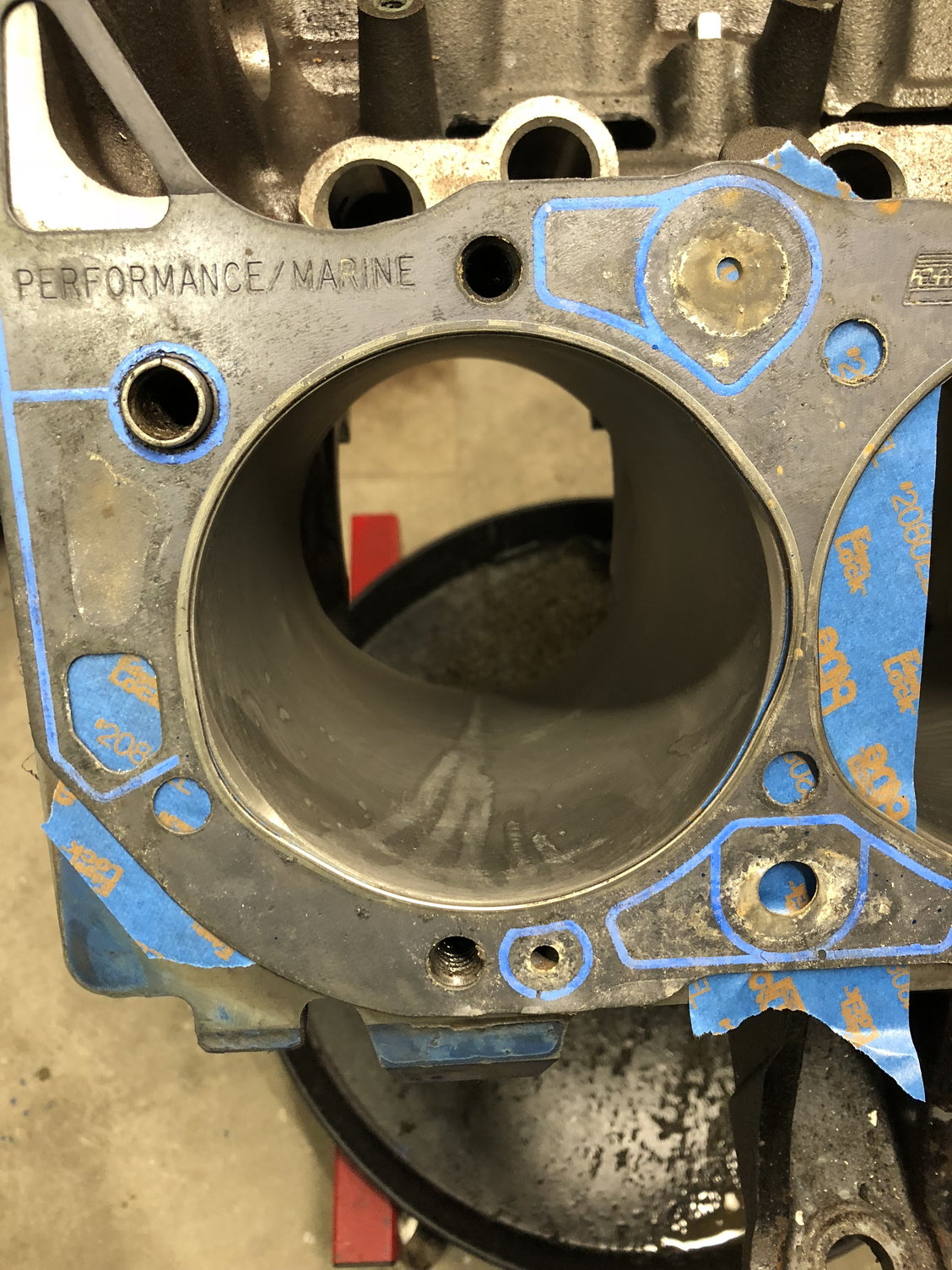

I know that we’re talking about a 454, but here’s a before and after pic of the notches before the machine work and after. On the liter size motorcycle engines all of the gains were in cleaning up the exhaust ports bumping it from 175hp to over 200 - which is huge. Compression and revs are nothing if you can’t get the gassed out. Unshrouding is a big deal on smaller (454) engines where the power is found in the revs.

#18

Registered

I talked to Valako the other day and he did do a back to back on std 454 bore 9.5 comp build before and after with Merlin heads 2.30 valve and said it was a solid 15-17 plus torque all the way through the pull. Not a radical build. Would I personally pull an engine or two and tear down to bore notch? No. Would I if engines were build in process absolutely. Can also open the door to cam change etc as well to add to the increase in power. It came at no surprise when jim said it was well worth doing. So based on rpm it's pretty simple to figure the hp increase. Little less than I anticipated but I suppose that can vary depending on how aggressive of a job as well. I do recall when he's done mine he always took precautions on what pistons and how far down the top/firing ring be on the piston. Makes sense.

#19

Registered

I don`t like how that narrows the space between cylinders.

I want more material there not less.

I want more material there not less.

#20

Registered

Thread Starter

Ive always heard the rule of 52% valve size to bore ratio was optimal on a bbc. A 4.250-4.310 (454-468) nets roughly a 2.25 diameter valve. A 4.500-4.600 bore, you start getting into needed 2.30+ valve diameters. Theres a thread over on speedtalk about this, i guess a bunch of drag race guys found on smaller bore stuff, going back to smaller valve netted more power, although the flow bench showed a drop in cfm.

im not positive on this , but i belive thats why afr offers a 290cc oval, with a 2.25 valve , and a 300cc oval, with a 2.30 valve. One is a better fit for a 427/454/496, the other is better for a 502/540/565. VALVE / BORE Ratio

The valve to bore ratio should be:

52-52.5% of the bore for Wedge heads.

53-53.5% for Canted valve, rotated canted valve (Mopar P/S hemi) and true Hemi.

If you decrease intake exhaust ratio down to 70-71% you can move both intake and

exhaust valves over to the exhaust side and increase intake valve size by .5-1%.

Anytime you increase valve size over the above stated Valve/Bore ratio you will see

a small gain in CFM but the discharge coefficient drops and takes your power with it.

An over shrouded valve instills a host of nasty scenario's, the two worst being

decreased discharge coefficient and increased reversion below and above intake

tuned power band.

(according to Darin Morgan)

im not positive on this , but i belive thats why afr offers a 290cc oval, with a 2.25 valve , and a 300cc oval, with a 2.30 valve. One is a better fit for a 427/454/496, the other is better for a 502/540/565. VALVE / BORE Ratio

The valve to bore ratio should be:

52-52.5% of the bore for Wedge heads.

53-53.5% for Canted valve, rotated canted valve (Mopar P/S hemi) and true Hemi.

If you decrease intake exhaust ratio down to 70-71% you can move both intake and

exhaust valves over to the exhaust side and increase intake valve size by .5-1%.

Anytime you increase valve size over the above stated Valve/Bore ratio you will see

a small gain in CFM but the discharge coefficient drops and takes your power with it.

An over shrouded valve instills a host of nasty scenario's, the two worst being

decreased discharge coefficient and increased reversion below and above intake

tuned power band.

(according to Darin Morgan)