O2 Sensor question

#21

Registered

i have a wideband on the port side header without all that and it reads maybe .2 leaner, but they are consistent with each other. Iím sure that itís not as good as a sensor directly plugged into dyno headers but it seems adequate. Fairly mild NA build set to 12.8 so hopefully thatís enough fudge room.

#23

FWIW, one other thing I did and I don't know if it helped is that I run open loop, no learn until 1500 rpm. My thought is the higher the rpm, the more consistent the exhaust flow and less likely to have water hit the O2, also, it should be hotter and more likely to flash off any condensation. Like I said - not sure if this helps, not sure if Holley shuts the power off to the O2 if its not in closed loop, but this Bosch O2 has lasted....and I've not had to hook up the PC in over 3yrs.

#24

For me it was pretty instant. Water shorts it out, the computer thinks the motor is lean and it dumps gas at it, motor dies. I didn't notice any signs before hand or felt it was getting worse over time. I went to the Innovative mentioned and have had well over 100 hrs on this current sensor w/o issue. I too verified the reading with the Innovative to be within 0.1-0.2 of the reading w/o it; I only have one O2 so I tested back-to-back using the same sensor. If you look at the Innovative, you clock it so the inlet is facing into the exhaust stream. On the bottom of the cylinder that is in the exhaust stream, it is angled to, in theory, create a low pressure area that helps draw the exhaust stream through the inlet port, up to the O2 sensor area and out the exit port. It's pretty cool.

FWIW, one other thing I did and I don't know if it helped is that I run open loop, no learn until 1500 rpm. My thought is the higher the rpm, the more consistent the exhaust flow and less likely to have water hit the O2, also, it should be hotter and more likely to flash off any condensation. Like I said - not sure if this helps, not sure if Holley shuts the power off to the O2 if its not in closed loop, but this Bosch O2 has lasted....and I've not had to hook up the PC in over 3yrs.

FWIW, one other thing I did and I don't know if it helped is that I run open loop, no learn until 1500 rpm. My thought is the higher the rpm, the more consistent the exhaust flow and less likely to have water hit the O2, also, it should be hotter and more likely to flash off any condensation. Like I said - not sure if this helps, not sure if Holley shuts the power off to the O2 if its not in closed loop, but this Bosch O2 has lasted....and I've not had to hook up the PC in over 3yrs.

#25

Registered

Arctic, what about putting a bung where YOU want it. That would seem to be a viable solution. Get your 10 or 15 degrees angle from horizontal and try for 18" from the exhaust valves. Or does Lightning say where you can put the bung?

#26

Platinum Member

Its been said more than once on here that Lightning headers revert water as bad as cast manifolds, I tend to believe that now!

#28

Registered

I ran O2 sensors on mine full time and didn't have ANY issues in the 30 hours I put on it..

555 cid. cam was 239 / 246 duration

Running Eddie Marine manifolds.. They modified the tails by running the inner pipe past the outer pipe

They also put a bell on it to throw the water against the exhaust hoses..

555 cid. cam was 239 / 246 duration

Running Eddie Marine manifolds.. They modified the tails by running the inner pipe past the outer pipe

They also put a bell on it to throw the water against the exhaust hoses..

#29

Registered

OK, I am convinced. I was spouting a lot of car based theory. Which doesn't always fly in our marine environment.

Yesterday I got the chance to run the AEM 30-0300 UEGO gauge with factory calibrated Bosch LSU 4.9 wideband sensor.

It idled out and ran 20 minutes to a cove we hang at. Readings were consistent and appeared correct. 13.7 cruise, 11.9 to 12.4 on the secondaries. I'd call that good. Maybe I can go up one size on primary jets to richen the cruise. My carb place sent me some plus 1/ minus 1 jets. So,yuh maybe.

My idle mix is rich, so I'll get out there and back that off. And that may have contributed to my sensor shutting down.

Here is some theory about fails, one of which is rich fueling

https://www.nzefi.com/bosch-lsu-wide...-applications/

But I never had an issue til I let the boat sit for an hour or so, on the next start up the gauge read full lean, and never came back.

I'm going to do a test today where the sensor is removed from the exhaust, powered up and fed with brake cleaner or propane from a lighter. It's supposed to go rich when you do that. But at the same time they warn you that the thing gets so hot it can cause combustion. So fire extinguisher.

I hope and think that I am getting condensation in my exhaust. It ran in the yard twice, no issues. Including normal exhaust water. My exhaust flappers are gone, and I have GGB exhaust inserts right where the tails go into my 4" rubber hoses. So maybe I need to take out the inserts.

But I am guessing that the condensation could have caused my issue. So if the sensor is dead, which I expect, I will probably get a fresh sensor and that extender elbow that I ripped before.

That's an instant bolt up, plus it gets the sensor away from the wet. instead of having a bung put in at the angle that AEM specifies.

Yesterday I got the chance to run the AEM 30-0300 UEGO gauge with factory calibrated Bosch LSU 4.9 wideband sensor.

It idled out and ran 20 minutes to a cove we hang at. Readings were consistent and appeared correct. 13.7 cruise, 11.9 to 12.4 on the secondaries. I'd call that good. Maybe I can go up one size on primary jets to richen the cruise. My carb place sent me some plus 1/ minus 1 jets. So,yuh maybe.

My idle mix is rich, so I'll get out there and back that off. And that may have contributed to my sensor shutting down.

Here is some theory about fails, one of which is rich fueling

https://www.nzefi.com/bosch-lsu-wide...-applications/

But I never had an issue til I let the boat sit for an hour or so, on the next start up the gauge read full lean, and never came back.

I'm going to do a test today where the sensor is removed from the exhaust, powered up and fed with brake cleaner or propane from a lighter. It's supposed to go rich when you do that. But at the same time they warn you that the thing gets so hot it can cause combustion. So fire extinguisher.

I hope and think that I am getting condensation in my exhaust. It ran in the yard twice, no issues. Including normal exhaust water. My exhaust flappers are gone, and I have GGB exhaust inserts right where the tails go into my 4" rubber hoses. So maybe I need to take out the inserts.

But I am guessing that the condensation could have caused my issue. So if the sensor is dead, which I expect, I will probably get a fresh sensor and that extender elbow that I ripped before.

That's an instant bolt up, plus it gets the sensor away from the wet. instead of having a bung put in at the angle that AEM specifies.

Last edited by NHGuy; 08-19-2019 at 09:03 AM.

#30

Registered

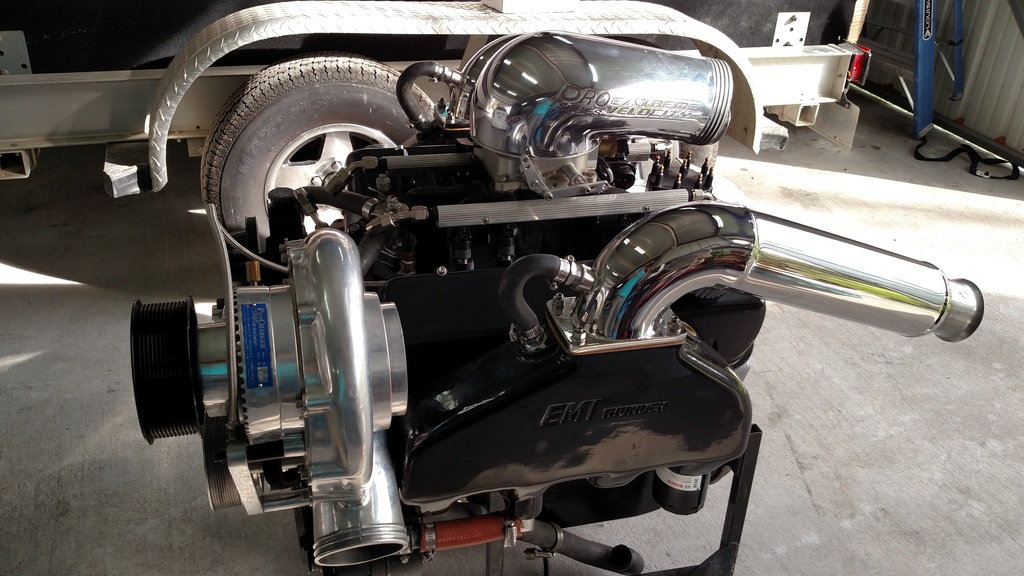

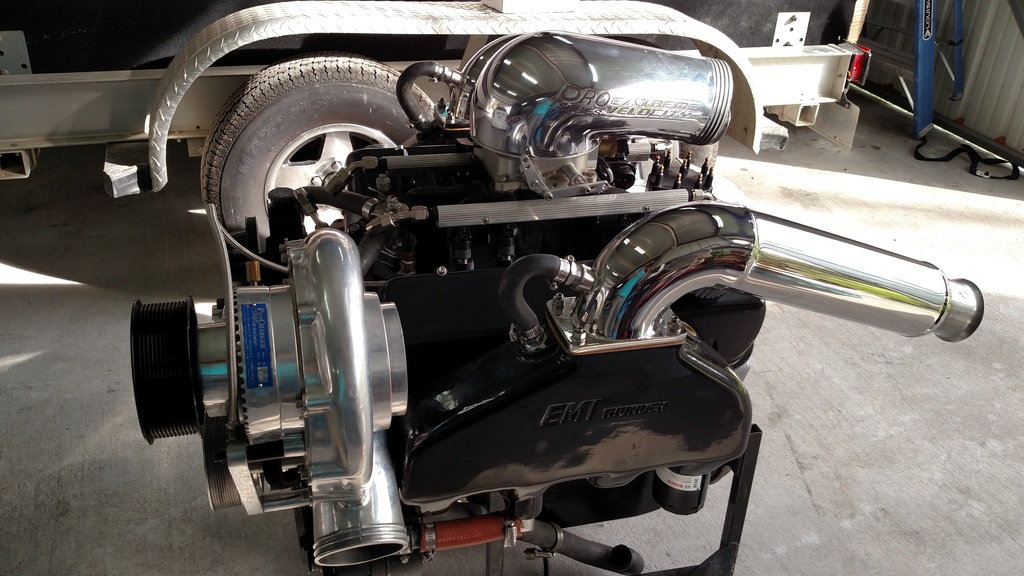

Would love to get header dimensions (ID's and lengths) + rate of fall and a good pic of how water is introduced into the exhaust stream.