Cylinder head/intake venting

#31

Registered

#32

Registered

Thread Starter

It's actually -10 hose with 1/2" fittings. My engine builder recommended it because he knows how I drive and I tend to push things pretty hard. I'll beat on it really hard and check temperatures all over the heads and block and it's super even and never too hot. A lot of people struggle with crossover systems this seems to be the ticket.

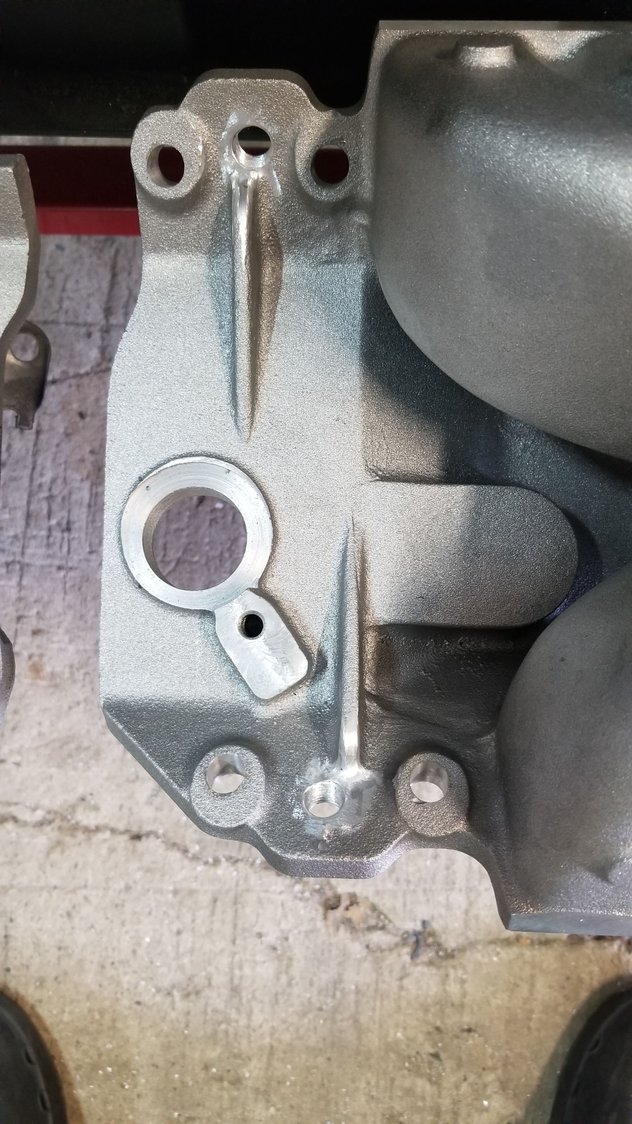

The webbing removed was to the top of the tapped hole.

Last edited by NautiB; 05-12-2020 at 05:16 PM.

#33

Registered

you don,t want or need a large diameter hose,all you are doing is releasing air that gets trapped in the rear of the block.this is only needed on siamese blocks.

The following users liked this post:

NautiB (05-13-2020)

#34

Registered

Thread Starter

#35

Registered

After spending $12k on a major rebuild and reading all the horror stories of crossover cooling systems, I wasn't going to take any chances. I even took a die grinder to my Hardin stainless water pump to improve flow, and carefully radius and polish surfaces the impellor rides on. I even opened up the water outlet in my headers to improve water flow. My engine builder does mostly high performance marine engines and he recommended the -10 line based on his experience. Our intent was to not only vent air/steam but to encourage flow to even out cylinder head temp. He's been doing this a long time and I trust him. I'm a fanatic for testing and measuring and the numbers I see are as close to perfect as anyone can expect. The amount of water coming out of my exhaust at idle is significantly greater than I see on any other boat so I know I am getting good flow. I will say this, when the water temps are in the low 50's or lower, my thermostat doesn't open, the 3 relief holes provide enough flow to keep the engine cool even while cruising at 60. I should mention too that the air temps were also in the low 50's.

The following users liked this post:

NautiB (05-13-2020)

#36

Registered

Thread Starter

After spending $12k on a major rebuild and reading all the horror stories of crossover cooling systems, I wasn't going to take any chances. I even took a die grinder to my Hardin stainless water pump to improve flow, and carefully radius and polish surfaces the impellor rides on. I even opened up the water outlet in my headers to improve water flow. My engine builder does mostly high performance marine engines and he recommended the -10 line based on his experience. Our intent was to not only vent air/steam but to encourage flow to even out cylinder head temp. He's been doing this a long time and I trust him. I'm a fanatic for testing and measuring and the numbers I see are as close to perfect as anyone can expect. The amount of water coming out of my exhaust at idle is significantly greater than I see on any other boat so I know I am getting good flow. I will say this, when the water temps are in the low 50's or lower, my thermostat doesn't open, the 3 relief holes provide enough flow to keep the engine cool even while cruising at 60. I should mention too that the air temps were also in the low 50's.

Curious, what are you running for a cam? You say you have higher water flow out the exhaust & no reversion?.. Thats something else thats always on my mind. Im cursed with a brain that wont shut off. lol

#37

Registered

I am using a Stewart racing high flow thermostat that came with 3 3/16" holes. My cam is a custom from Comp Cams, duration at .050" is 242/252 and lift is .623/.612. If you look at the picture, the water is injected into the exhaust right where the rubber hose is clamped so there is some distance between the runners and water entry point. The downward angle helps as well. I have a real lopey idle that I have to use a lot of timing tricks to keep running at 800rpm. Without the mufflers it sounds incredible. First time I started it in our harbor the echo sounded like thunder.

The following users liked this post:

NautiB (05-13-2020)

#38

Registered

Thread Starter

I am using a Stewart racing high flow thermostat that came with 3 3/16" holes. My cam is a custom from Comp Cams, duration at .050" is 242/252 and lift is .623/.612. If you look at the picture, the water is injected into the exhaust right where the rubber hose is clamped so there is some distance between the runners and water entry point. The downward angle helps as well. I have a real lopey idle that I have to use a lot of timing tricks to keep running at 800rpm. Without the mufflers it sounds incredible. First time I started it in our harbor the echo sounded like thunder.

I bet yours sounds great with that cam, love to hear it.

#39

Registered

Im using Hardin marine cross over kits with their thermostats. They tell you to drill them if needed. Your cam is pretty heavy on duration, for what looks to be a wet exhaust. Im not sure im looking or seeing what your talking about as to where the water is injected into the exhaust, coupler? Cant see the port side completely. My cam is deff milder that yours. Its from Crane. I had a rough experience with comp, long story. my duration is 226*in / 234*ex @ .050 & 587in 610ex lift w/ 112* LSA. Crane tells me I wont have reversion with this grind in my 502's but I swear its right on the verge. What "timing tricks" are you doing? Sounds interesting. Im running MSD digital 6M-3L. I like it because I can dial my rev limit and retard my timing at start up. Works good with the curve options of the distributor.

I bet yours sounds great with that cam, love to hear it.

I bet yours sounds great with that cam, love to hear it.

The following users liked this post:

NautiB (05-14-2020)

#40

Registered

Forgot to reply to your exhaust question. The water is injected at the end of the taper internally. There is an inner and out wall and the inner stops right at the end of the taper with about a .060" gap all the way around. So there is almost 16" between the end of the runners and where water is injected. The exhaust can get hot but you not enough to burn you.

The following users liked this post:

NautiB (05-14-2020)