Dart Big M Block Questions

#41

Registered

Nothing different props wouldn't help with. One for skiing, cruise and top speed. Easy, cheap and reliable

The following 2 users liked this post by underpsi68:

SB (01-05-2022), ThisIsLivin (01-12-2022)

#42

Registered

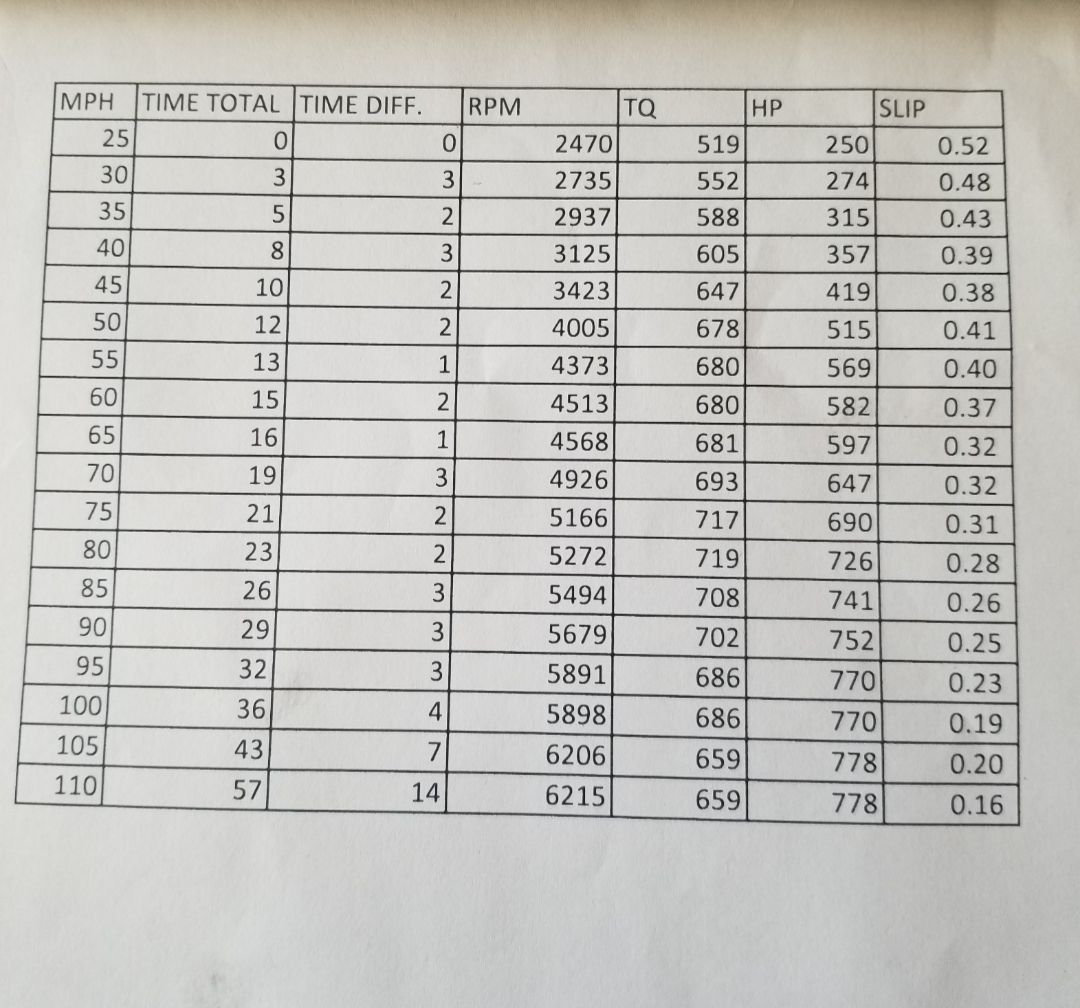

Having smart craft and the garmin linked together we collect a bunch of data on our boat. It's a 42 ft fountain with 6 drives and 1.35 ratio. We spin 30 pitch props. They dont pull much under 2700 rpm. So if you were to put a small enough prop on to get your low end throttle response, when that engine comes into its torque band it is going to spin the prop, then when it finally catches up you will break your bravo style drive. In theory it all sounds good but in the real world it is different. I will post one of our charts of a run so you can see how much harder they pull in the meat of the torque band.

#43

Registered

#44

VIP Member

Thread Starter

KWright,

The funny thing about that data chart is that it's likely about the same as one would be for my PQ280/496HO, as far as MPH/RPM. Right up until the 65MPH point. At which point mine taps out and yours keep going.

Thanks. Brad.

(937)545-8991

The funny thing about that data chart is that it's likely about the same as one would be for my PQ280/496HO, as far as MPH/RPM. Right up until the 65MPH point. At which point mine taps out and yours keep going.

Thanks. Brad.

(937)545-8991

Last edited by Brad Christy; 01-05-2022 at 04:57 PM.

#45

Platinum Member

Ded,

Don’t be sorry. That’s what I’m here for. If a 572 or whatever is the ticket, that’s what I’d build. God knows I’m the student here.

The ONE thing I don’t want is a scatterbox looking for an excuse. The plan would be to do the build, do the swap and sell an extremely low hour 496HO/ProCharger combo to recoup most of the cost. If the damned thing blows up, just on principle, I just might get buried in the boat. Same with the outdrive. What I want most of all is an ultra reliable boat that runs strong. I know it can be done. It’s just a matter of forming a plan and working the wrinkles.

George "DOESNT USE BRAVO GEARS" (at least, that’s what he tells me). He machines the casings to accommodate larger gears, shafts and U-joints. His “Stage 1” is supposedly good for 700HP for 200 hrs, with a two year warranty. I do get it, though, and, if another $15K is in the cards to make this all fly, the wife is gonna put her red headed clamps on it pretty quick. It’s already going to be hard enough to convince her we “need” the boat to go any faster than it does now. She didn’t grow up on an 85MPH, 21’ semi-flat bottom day cruiser, like I did. 67 already kinda has her white-knuckling it.

Thanks. Brad.

(937)545-8991

Don’t be sorry. That’s what I’m here for. If a 572 or whatever is the ticket, that’s what I’d build. God knows I’m the student here.

The ONE thing I don’t want is a scatterbox looking for an excuse. The plan would be to do the build, do the swap and sell an extremely low hour 496HO/ProCharger combo to recoup most of the cost. If the damned thing blows up, just on principle, I just might get buried in the boat. Same with the outdrive. What I want most of all is an ultra reliable boat that runs strong. I know it can be done. It’s just a matter of forming a plan and working the wrinkles.

George "DOESNT USE BRAVO GEARS" (at least, that’s what he tells me). He machines the casings to accommodate larger gears, shafts and U-joints. His “Stage 1” is supposedly good for 700HP for 200 hrs, with a two year warranty. I do get it, though, and, if another $15K is in the cards to make this all fly, the wife is gonna put her red headed clamps on it pretty quick. It’s already going to be hard enough to convince her we “need” the boat to go any faster than it does now. She didn’t grow up on an 85MPH, 21’ semi-flat bottom day cruiser, like I did. 67 already kinda has her white-knuckling it.

Thanks. Brad.

(937)545-8991

The following 2 users liked this post by articfriends:

chancer540 (02-26-2022), IGetWet (01-05-2022)

#46

Platinum Member

Arctic,

Just my Frankenstein mind wandering here....

I know this sort of thing happens all the time in the model boating world, because I've made "long" rods for many engines within our realm. It's pretty easy to do, with only a shim under the cylinder sleeve equal in thickness to the difference is rod length from stock. While I'm sure there are a number of "lack of" success stories that didn't bother reporting back, I got many calls from very satisfied customers. Being two strokes, with piston/sleeve transfer ports for valves, there are other factors coming into play when doing these sorts of things in our model boating world that are not in play with cam valved four strokes in our monster motor world, but reducing rod angle was one of the benefits being chased after.

Since rod angle seems to be the primary concern for the 632, If one were to go with, say, a 565 build, would it serve to start with a 10.2 deck block and use longer rods? Just doing the basic math, using 6.7" rods instead of 6.385 rods takes up all but the last .085" of the difference between the 10.2" and the 9.8" decks, assuming the difference would be exactly .400" between the two deck heights. An automotive machine shop could easily take that off and one would be back to nominal deck height and an even milder yet rod angle. Would there be any benefit in this? Any harm? I know other alternative parts would come into necessity, like pushrods, but that shouldn't be an hill for a climber, I wouldn't think.

After some rudimentary AutoCad work, some numbers, if applicable, based on 4.25" stroke:

6.385" rods reaches max rod angle of approx.18.4 degrees of rod angle, at 71.6 degrees ATDC and 1.7805" below TDC.

6.700" rods reaches max rod angle of approx.17.6 degrees of rod angle, at 72.4 degrees ATDC and 1.7960" below TDC.

Don't ever let a self employed toolmaker get bored...... Crap like this happens: Scratch built 30cc inline twin nitro engine (I did that, BTW.)

Crap like this happens: Scratch built 30cc inline twin nitro engine (I did that, BTW.)

Thanks. Brad.

(937)545-8991

Just my Frankenstein mind wandering here....

I know this sort of thing happens all the time in the model boating world, because I've made "long" rods for many engines within our realm. It's pretty easy to do, with only a shim under the cylinder sleeve equal in thickness to the difference is rod length from stock. While I'm sure there are a number of "lack of" success stories that didn't bother reporting back, I got many calls from very satisfied customers. Being two strokes, with piston/sleeve transfer ports for valves, there are other factors coming into play when doing these sorts of things in our model boating world that are not in play with cam valved four strokes in our monster motor world, but reducing rod angle was one of the benefits being chased after.

Since rod angle seems to be the primary concern for the 632, If one were to go with, say, a 565 build, would it serve to start with a 10.2 deck block and use longer rods? Just doing the basic math, using 6.7" rods instead of 6.385 rods takes up all but the last .085" of the difference between the 10.2" and the 9.8" decks, assuming the difference would be exactly .400" between the two deck heights. An automotive machine shop could easily take that off and one would be back to nominal deck height and an even milder yet rod angle. Would there be any benefit in this? Any harm? I know other alternative parts would come into necessity, like pushrods, but that shouldn't be an hill for a climber, I wouldn't think.

After some rudimentary AutoCad work, some numbers, if applicable, based on 4.25" stroke:

6.385" rods reaches max rod angle of approx.18.4 degrees of rod angle, at 71.6 degrees ATDC and 1.7805" below TDC.

6.700" rods reaches max rod angle of approx.17.6 degrees of rod angle, at 72.4 degrees ATDC and 1.7960" below TDC.

Don't ever let a self employed toolmaker get bored......

Crap like this happens: Scratch built 30cc inline twin nitro engine (I did that, BTW.)

Crap like this happens: Scratch built 30cc inline twin nitro engine (I did that, BTW.)Thanks. Brad.

(937)545-8991

The following 3 users liked this post by articfriends:

#47

VIP Member

Thread Starter

I wouldnt go out of my way to take .100 off a deck on a new block, Id only do it as a worst case scenario for other reasons. Intake/head match would also be a concern as other machining would be required for that in between deck height, adjustable height distributor, etc, Id just adjust rod length or pin height when you order your pistons.

it was just a thought. But I get that there are more pieces to the puzzle than am aware, and that was obviously one of them.

Appreciate the insight.

Thanks. Brad.

(937)545-8991

#48

VIP Member

Thread Starter

Unless George at AADS started recently using the lower gears recently brought to market by Dave Smith "AKA as Smitty" on here, he IS using Bravo gears in his upper for sure and most likely the lower, they may be XR gears BUT there IS no other gears you can purchase today that fit a Bravo housing unless were talking a IMCO SCX which starts at 17,000.

If I remember our convo correctly, George machines the case(s) to allow for larger parts.

His “Stage 1” is supposedly good for 700HP for 200hrs of service. Don’t know if anybody has any feedback ….?

Thanks. Brad.

(937)545-8991

#49

Registered

Brad, conventional logic is that rid/stroke needs to be greater than 1.5. Also that you need a little over an inch of compression height to have a good piston and ring package. That means roughly 565” 9.8” deck height 598” 10.2” deck height (assuming 4.6” bore)

There are a lot of people breaking these rules, but that’s the conventional/conservative logic.

There are a lot of people breaking these rules, but that’s the conventional/conservative logic.

Last edited by hogie roll; 01-05-2022 at 10:05 PM.

#50

Registered

I had George do a stage 2 on my drive. He uses a bigger bearing and a custom shaft but uses stock gears. I also had him Cryo the gears to remove internal stresses. He also will tell you no hole shots. I'm only running an NA 524 in a Velocity 280 and I run north of 80 with a full tank and 5 adults. But there is no way I would even think about pulling a skier without dropping 6 pitches on the prop.