We hurt the 496....

#71

VIP Member

Drag,

At more than double the cost of Molnar, and more expensive than Oliver, these rods are anything by ďinexpensiveĒ. If I were going to blow my budget, Iíd just go ahead and get the Olivers. Molnar rods, while indeed forged in China, are not coming out of the same foundry as other rods. Tom uses a specific foundry that follows his exact specs for both metallurgy and tempering (Tom Molnar was the chief metallurgical engineer at Oliver before starting his own company), and are then finished in Michigan. I really like what Iíve read from the various forums Iíve stumbled across (mostly street/drag), and Iím reassured by the builder that they are more than adequate for my application. The Molnar-specific ARP bolts, and the engineering behind them, are just icing on the cake.

Thanks. Brad.

At more than double the cost of Molnar, and more expensive than Oliver, these rods are anything by ďinexpensiveĒ. If I were going to blow my budget, Iíd just go ahead and get the Olivers. Molnar rods, while indeed forged in China, are not coming out of the same foundry as other rods. Tom uses a specific foundry that follows his exact specs for both metallurgy and tempering (Tom Molnar was the chief metallurgical engineer at Oliver before starting his own company), and are then finished in Michigan. I really like what Iíve read from the various forums Iíve stumbled across (mostly street/drag), and Iím reassured by the builder that they are more than adequate for my application. The Molnar-specific ARP bolts, and the engineering behind them, are just icing on the cake.

Thanks. Brad.

__________________

Formula 353

Merc Racing 540s

Formula 353

Merc Racing 540s

The following users liked this post:

SB (09-09-2024)

#72

VIP Member

Thread Starter

OK, OK... You talked me into it....

I'll be making the AN weld bungs from 316 round bar. This means the entire assembly will be 316 stainless. I have the tubing in hand, and it almost looks polished (I did not order the polished material). After passivation, they should look pretty nice.

We are actively working on fixturing components as I type, and I will be starting on assembly members shortly. It's on the slow boat from China, but it's coming together.

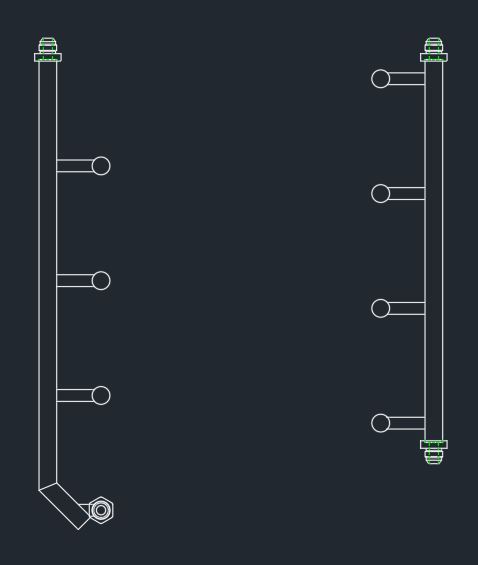

This is a basic representation of what it will end up like.

The mounting tabs will be there, as well, I just didn't feel like taking the time to draw them out for this pic.

The hex on the #2 cylinder injector cup is an AN fitting welded on top of the injector cup. My intention is to attach the feed line to the AN fitting near the #1 cylinder, plumb the two rails together at the rear of the engine, and the return line will exit vertically from the #2 cylinder injector cup.

Thanks. Brad.

Last edited by Brad Christy; 09-10-2024 at 05:14 PM.

#74

VIP Member

Thread Starter

Guys,

So, I've managed to snag a Holley HP ECM and harness, used, through the builder that's doing the work. I will not be horse collared by the PCM555 moving forward. Which means I will be brooming it. He is also going to be doing a custom grind cam for me that will render some of the benefits of the ProCharger, closing the gap between the OEM and the Raylar 211 cam, while still avoiding any reversion. So that brings on a question...

While I was contemplating the Raylar cam, I was told that I could swap the cam without worrying about the lifters, due to their being roller lifters, so I'm assuming a good shape used cam could be used in another 496 with the same lifters. Would there be any interest in a PCM555, with or without harness, flashed with a Whipple stage 2 tune, and a (assumingly) good shape 496HO cam? This seems like a prime opportunity for someone looking to upgrade their NA base MAG.

I also have a TechMate Pro that I will no longer have any use for.

I will be posting these items in the swap shop when I get back from next week's vacay, but I wanted to get a feel for the prospect.

Thanks. Brad.

So, I've managed to snag a Holley HP ECM and harness, used, through the builder that's doing the work. I will not be horse collared by the PCM555 moving forward. Which means I will be brooming it. He is also going to be doing a custom grind cam for me that will render some of the benefits of the ProCharger, closing the gap between the OEM and the Raylar 211 cam, while still avoiding any reversion. So that brings on a question...

While I was contemplating the Raylar cam, I was told that I could swap the cam without worrying about the lifters, due to their being roller lifters, so I'm assuming a good shape used cam could be used in another 496 with the same lifters. Would there be any interest in a PCM555, with or without harness, flashed with a Whipple stage 2 tune, and a (assumingly) good shape 496HO cam? This seems like a prime opportunity for someone looking to upgrade their NA base MAG.

I also have a TechMate Pro that I will no longer have any use for.

I will be posting these items in the swap shop when I get back from next week's vacay, but I wanted to get a feel for the prospect.

Thanks. Brad.

#75

Registered

I havent followed the whole whole thing but .. I had Molnar carnks and rods and they held up great.

How tall is your hatch ?

How much $$ is it going to cost to rebuild these in total?

Reason I ask is , I`m getting some Eddie Young Engines and mine are for sale.

Spent $3k per engine on head work, everything new besides the valves. Valves back cut, all new guides, valve job, springs retainers, etc etc

They will be converted to Holley to solve the distribution and timing issue.

Coil on plug

$22K complete .

How tall is your hatch ?

How much $$ is it going to cost to rebuild these in total?

Reason I ask is , I`m getting some Eddie Young Engines and mine are for sale.

Spent $3k per engine on head work, everything new besides the valves. Valves back cut, all new guides, valve job, springs retainers, etc etc

They will be converted to Holley to solve the distribution and timing issue.

Coil on plug

$22K complete .

The engines are tall deck Dart blocks, with new JE positions. The block has never been bored.

The rods are Carillo, and the crank is from Lunati. The crank was re-done by Lunati directly on the current build and set with 2- keyways for the blower pulley.

With a change of fuel, and a change of the lower pulley, 1300-1350 is what they would run.

He had them dialed back to the current setting for ultimate reliability, and loves the current performance level.

15-20 hours max on the engines since they were completely redone to the current specifications.

* The heads are Dart Pro-1 that are ported

* The ignition controller is a MEFI 4 with Daytona sensor controller and coil.

* Isky solid roller cam with T&D shaft. 1.7:1 rockers

* Positions are JE

* Block is a Dart tall deck

* Rods are Carillo

The rods are Carillo, and the crank is from Lunati. The crank was re-done by Lunati directly on the current build and set with 2- keyways for the blower pulley.

With a change of fuel, and a change of the lower pulley, 1300-1350 is what they would run.

He had them dialed back to the current setting for ultimate reliability, and loves the current performance level.

15-20 hours max on the engines since they were completely redone to the current specifications.

* The heads are Dart Pro-1 that are ported

* The ignition controller is a MEFI 4 with Daytona sensor controller and coil.

* Isky solid roller cam with T&D shaft. 1.7:1 rockers

* Positions are JE

* Block is a Dart tall deck

* Rods are Carillo

#76

Registered

I have miles of receipts.

probably a little much for your drive lol

probably a little much for your drive lol

The following users liked this post:

Diamond Dave (09-11-2024)

#77

Offshoreonly Advertiser

https://www.titanfittings.com/

__________________

Marc

www.mercruiserparts.com

www.go-fast.com

www.bammarine.com

www.cyborgtransmissions.com

It's not alive -www.BoatStuffExpress.com - temporarily retired

Marc

www.mercruiserparts.com

www.go-fast.com

www.bammarine.com

www.cyborgtransmissions.com

It's not alive -www.BoatStuffExpress.com - temporarily retired

#78

VIP Member

Thread Starter

Dan,

I appreciate the offer, but, yeahÖ. WAY too much for our Bravo 1. Hell, Iím pushing it pretty hard, as it is. Additionally, there is no farqing way Iím either getting one of those under my hatch or talking the wife into spending even half that for one of them.

Honestly, Iíve added up the major buys involved in this; pistons, rods, cam, head gaskets, Swaintech TBC on the pistons, machine shop cost, builderís fees, etcÖ. I think Iím back together for somewhere between $5K and $10K. What Iíve listed so far is still just under or right at $5K. The Holley HP and harness are actually a net gain, money-wise, accounting for selling the 555 instead of having to send it to Boos or Whipple for tuning.

Thanks. Brad.

I appreciate the offer, but, yeahÖ. WAY too much for our Bravo 1. Hell, Iím pushing it pretty hard, as it is. Additionally, there is no farqing way Iím either getting one of those under my hatch or talking the wife into spending even half that for one of them.

Honestly, Iíve added up the major buys involved in this; pistons, rods, cam, head gaskets, Swaintech TBC on the pistons, machine shop cost, builderís fees, etcÖ. I think Iím back together for somewhere between $5K and $10K. What Iíve listed so far is still just under or right at $5K. The Holley HP and harness are actually a net gain, money-wise, accounting for selling the 555 instead of having to send it to Boos or Whipple for tuning.

Thanks. Brad.

The following users liked this post:

ICDEDPPL (09-11-2024)

#79

Registered

I`ve never seen a bill that low for a rebuild but I hope that

it works out for you !!

it works out for you !!

#80

VIP Member

Thread Starter

Oh, Iím not so naive to think that budgets donít blow up in the dead of night. Iím fully aware that battle plans rarely survive initial contact with the enemy.

Adding up what Iíve mentioned, and adding in the 600SCI oil cooler that has been suggested to me, and a new fuel pressure regulator, assuming what the builder told me for the machine shop cost is correct, Iím at $5600, engine out, rebuilt, and back in, parts and labor. This does not include new valve springs or gaskets other than head gaskets. The labor cost may increase a bit with the addition of the Holley HP, as I understand itís not a direct plug-n-play on the 496, but can easily be made to work. Iím sure there will be other sundries that will add up. But Iím hoping to keep it under $10K. That said, I am actively combatting scope creep tooth and nail. There is a ton of stuff Iíd LIKE to do.

Thanks. Brad.