Newbie 21' scarab build

#51

Registered

Watch out about putting your MSD box on the manifold (I realize the manifold is designed to mount it there). The electronics are completely potted internally but heat and ultrasonic vibration are MSD killers. Even putting it on a bracket off of the engine can act like mounting it to a tuning fork and over time shake it to death. Best place for it, is high and dry on the stern where it can stay cool and have the least about of ultrasonic vibration.

Worked in the Nascar industry for 6 years.

Worked in the Nascar industry for 6 years.

Last edited by speeddemon651; 04-30-2014 at 07:27 PM.

#52

Registered

Thread Starter

Watch out about putting your MSD box on the manifold (I realize the manifold is designed to mount it there). The electronics are completely potted internally but heat and ultrasonic vibration are MSD killers. Even putting it on a bracket off of the engine can act like mounting it to a tuning fork and over time shake it to death. Best place for it, is high and dry on the stern where it can stay cool and have the least about of ultrasonic vibration.

Worked in the Nascar industry for 6 years.

Worked in the Nascar industry for 6 years.

#53

Registered

Thread Starter

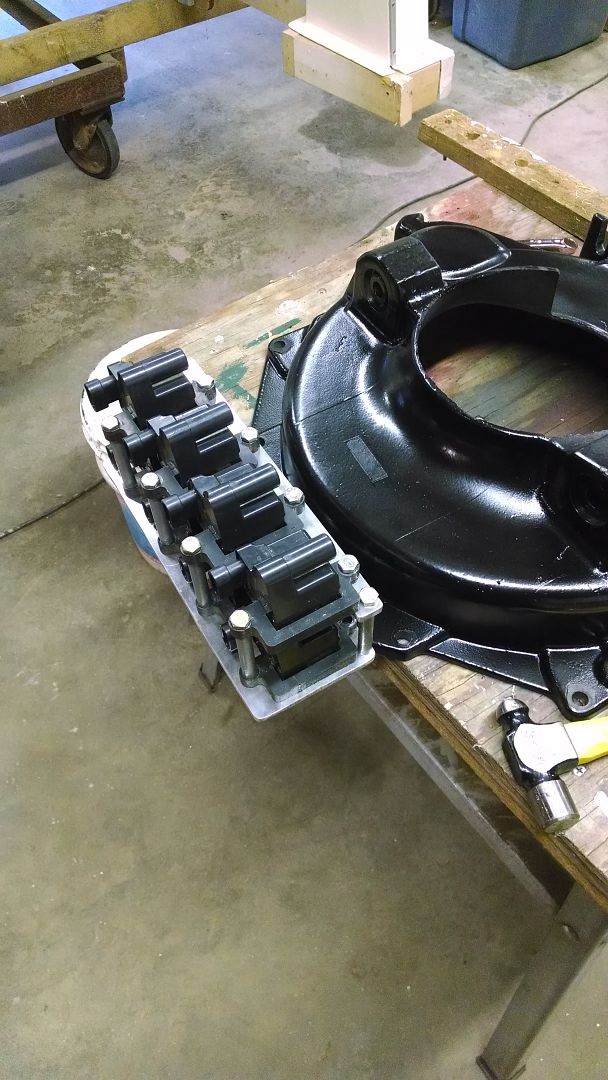

manifolds came in. im planning on making my own ss semi dry risers but after seeing these in person i think it will be harder than i thought.

[URL=http://s47.photobucket.com/user/wideopenford/media/IMG_20140510_151007907.jpg.html] [

[

i was thinking 3 inch inner and 3.5 outter. the circumfernce of that exhaust oval is around 10 1/4 and 3 inch pipe circumfernce is 9 1/2 so that gets me close if i massage the end of the pipe into this oval shape

the water jackets are my second problem. im thinking when i give the guy the drawing to burn the mounting flange, make it dry joint and just drill 3/4 NPT hole in the center of the front water passage so i can then just have a jumper hose, and weld a bung on the ss pipe. if any one has ever done this before please tell me im not crazy.......

[URL=http://s47.photobucket.com/user/wideopenford/media/IMG_20140510_151007907.jpg.html]

[

[i was thinking 3 inch inner and 3.5 outter. the circumfernce of that exhaust oval is around 10 1/4 and 3 inch pipe circumfernce is 9 1/2 so that gets me close if i massage the end of the pipe into this oval shape

the water jackets are my second problem. im thinking when i give the guy the drawing to burn the mounting flange, make it dry joint and just drill 3/4 NPT hole in the center of the front water passage so i can then just have a jumper hose, and weld a bung on the ss pipe. if any one has ever done this before please tell me im not crazy.......

#55

Registered

Join Date: Dec 2012

Location: Peoria, IL

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

#57

Registered

Thread Starter

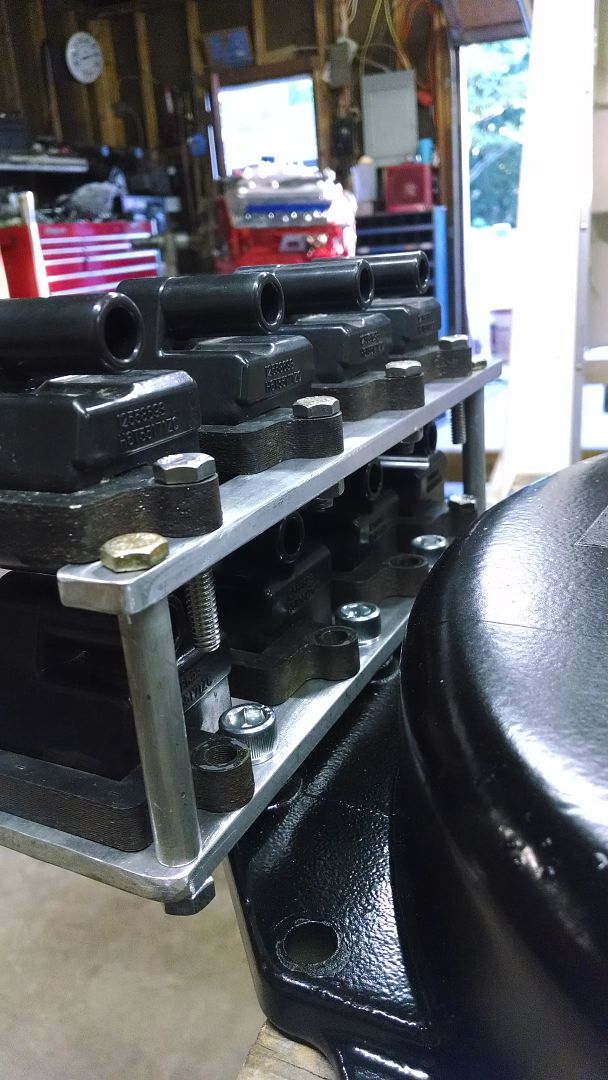

yea i just bought some off summit. i got the motor in and they work. i havent lined it up yet but it looks like it will work.

got bell housing on. actually had to trim it a little coat it was hitting the bolts on rear cover. i wish i had a bridgeport machine big drill bit took care of it nicely.

big drill bit took care of it nicely.

the flex plate works to. bought a flywheel from rockauto for like 80 bucks. 2002 5.3L 1500. only thing thats different is the bolts there metric.

got bell housing on. actually had to trim it a little coat it was hitting the bolts on rear cover. i wish i had a bridgeport machine

big drill bit took care of it nicely.

big drill bit took care of it nicely.

the flex plate works to. bought a flywheel from rockauto for like 80 bucks. 2002 5.3L 1500. only thing thats different is the bolts there metric.

#58

Registered

Join Date: Oct 2012

Location: madrid, ia

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

hmm interesting about your bolts hitting. maybe there are slight changes in differnt castings of the bellhousing. thats a nice way to set your coils up. my engine should be home very soon, so I'll get some shots of the set up alex built for these engines. did you keep your factory intake? if you ever want to run efi I can tell you get the schematics from the dealership. I found a ton of them online but some of them are slightly different. I'll have to post my dyno results once i get that done. I can't wait to see your boat finished up man. you pick out a color scheme for your boat? or are you staying all white?

#59

Registered

Join Date: Aug 2013

Location: Winchester , va

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Your getting there! Instead of drilling on the bell housing, I put regular hex bolts in the cover and had plenty clearance. I just built a 6.0 for my checkmate. First start yesterday. It's a 403 stroker. The 5.3 started knocking a few weeks ago.

#60

Registered

Join Date: Aug 2013

Location: Winchester , va

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts