40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#1081

Gold Member

Makes me realize just how hard it is to make drives survive especially under big power.

The following users liked this post:

kidturbo (02-22-2021)

#1082

Registered

Thread Starter

We are up to like $700 in gear oil wasted, and only about $250 in diesel fuel burned so far... Even counting the CP3 failure, when she dumped $50 worth of that $250 into the bilge last week... lol

#1083

Gold Member

The power part is doable. Design in general is solid. The drop boxes are happy when ya give em a good oil supply all the time now. Those are ironed out, and with a little fine tuning would stick with design. The lowers however, bearings don't like water, which leads to failures, which leads to gears getting chunked out the case. Key to any drive is keeping the oil clean and water out. These units would ultimately fail behind a 12hp Honda if you left it parked in the water for a month first..

We are up to like $700 in gear oil wasted, and only about $250 in diesel fuel burned so far... Even counting the CP3 failure, when she dumped $50 worth of that $250 into the bilge last week... lol

We are up to like $700 in gear oil wasted, and only about $250 in diesel fuel burned so far... Even counting the CP3 failure, when she dumped $50 worth of that $250 into the bilge last week... lol

#1084

Registered

Thread Starter

I narrowed it down today to one of the shaft seals, but I believe it's the input. At least that's the only place Air was blowing out from.. But have to check the bellows tomorrow and see what the u-joints look like. I couldn't get a soap bubble from the lower one, or any other seam, bolt, or plug after an hour with air on it and bottle of soap. But it was sure blowing air out the bellows weep hole we drilled into the upper case behind the drop box. And I have a good pic showing why I don't believe it's the lower shaft seal, but first, I'm going to get food.. Haven't ate a thing all day..

#1085

Registered

I have seen both case split line and shaft seal leaks on industrial machinery under load, never failed a pressure test, and we rebuilt them over and over and never got it solved u til we remachined every surface... no design change. itís frustrating I know. Shaft flex, case flex etc Iím sure you are looking into it all.

donít rule out thermal, if the gear oil/air gets warm then contracts it could be pulling water in if the negative pressure is deforming the shaft seals. I think you put a breather hole in to release case pressure from heat right? You are putting huge heat in with the big power low RPM, probably getting good temp in them every time you get up on plane.

donít rule out thermal, if the gear oil/air gets warm then contracts it could be pulling water in if the negative pressure is deforming the shaft seals. I think you put a breather hole in to release case pressure from heat right? You are putting huge heat in with the big power low RPM, probably getting good temp in them every time you get up on plane.

The following users liked this post:

kidturbo (02-22-2021)

#1086

Registered

Thread Starter

Three reasons I don't believe it's case flexing or heat related.

First, the seams were all painted over while drives were off replacing the upper gearbox hardware. And I just touched the nicks along those lines up again last week. So we will see I guess.

Second, they were recently opened up by Weismann, the O-rings replaced, and properly torqued, one would hope. No leaks on any of the bolts, so we gotta assume that is all good. Plus at speed, there is less than a inch of the whole lower case in the water. When I checked them directly after a couple runs, oil looks good. Let em set in the water for 24hrs, light trace of water. 72hrs, milkshakes..

Third, and a good point I spoke about with best drive guy I know today. These lowers are atmospheric vented above the waterline into the upper case. They can't pull a vacuum, any more than they could build up pressure. That vent port is what I used to pressure test on today.

Now all that said, the braided vent tube is a possible source of leaks, I've never pressure tested that old line. Tomorrow when I pull the bellows back to check things, I'm gonna yank those lines off and check just to be sure.

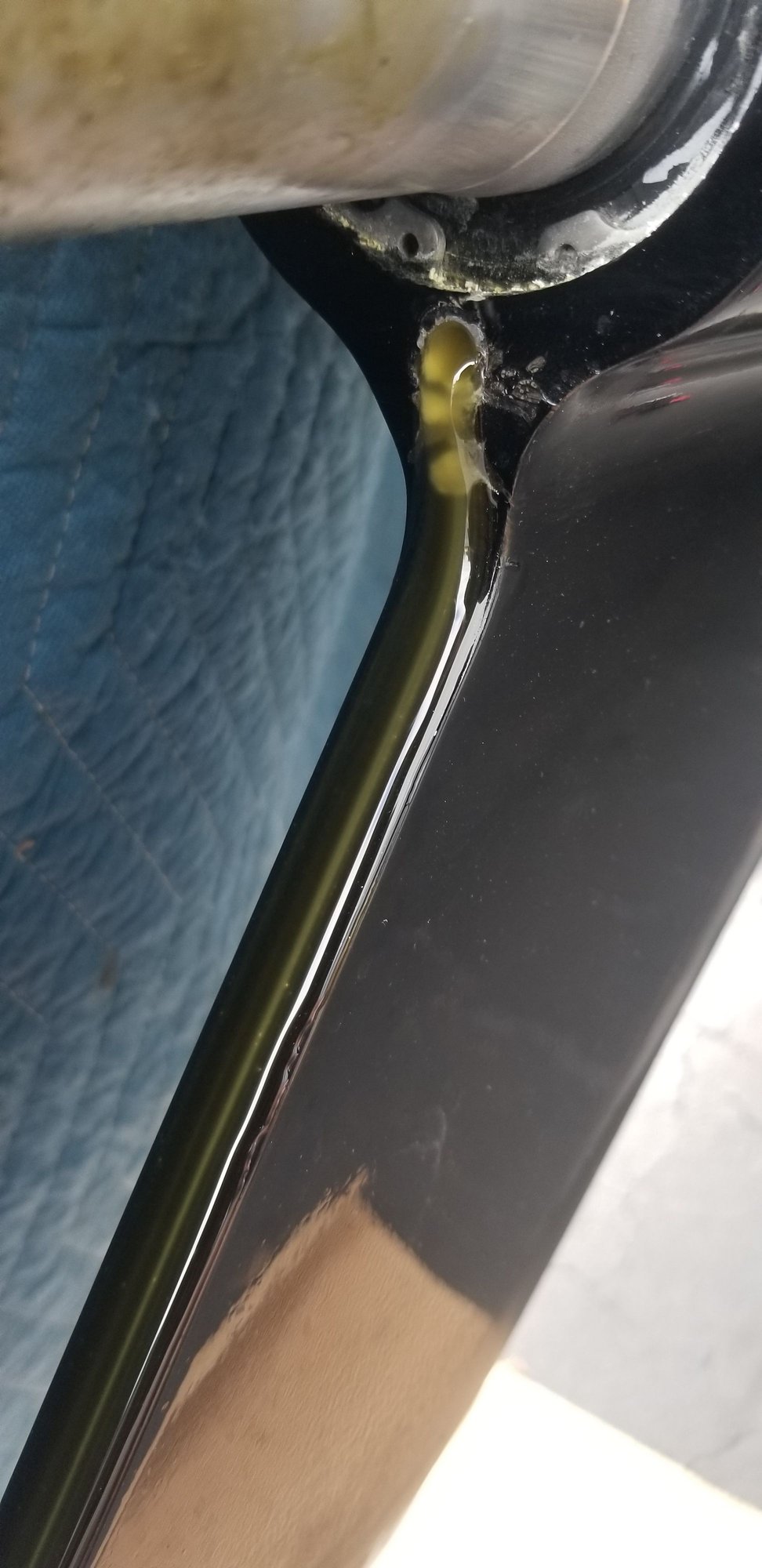

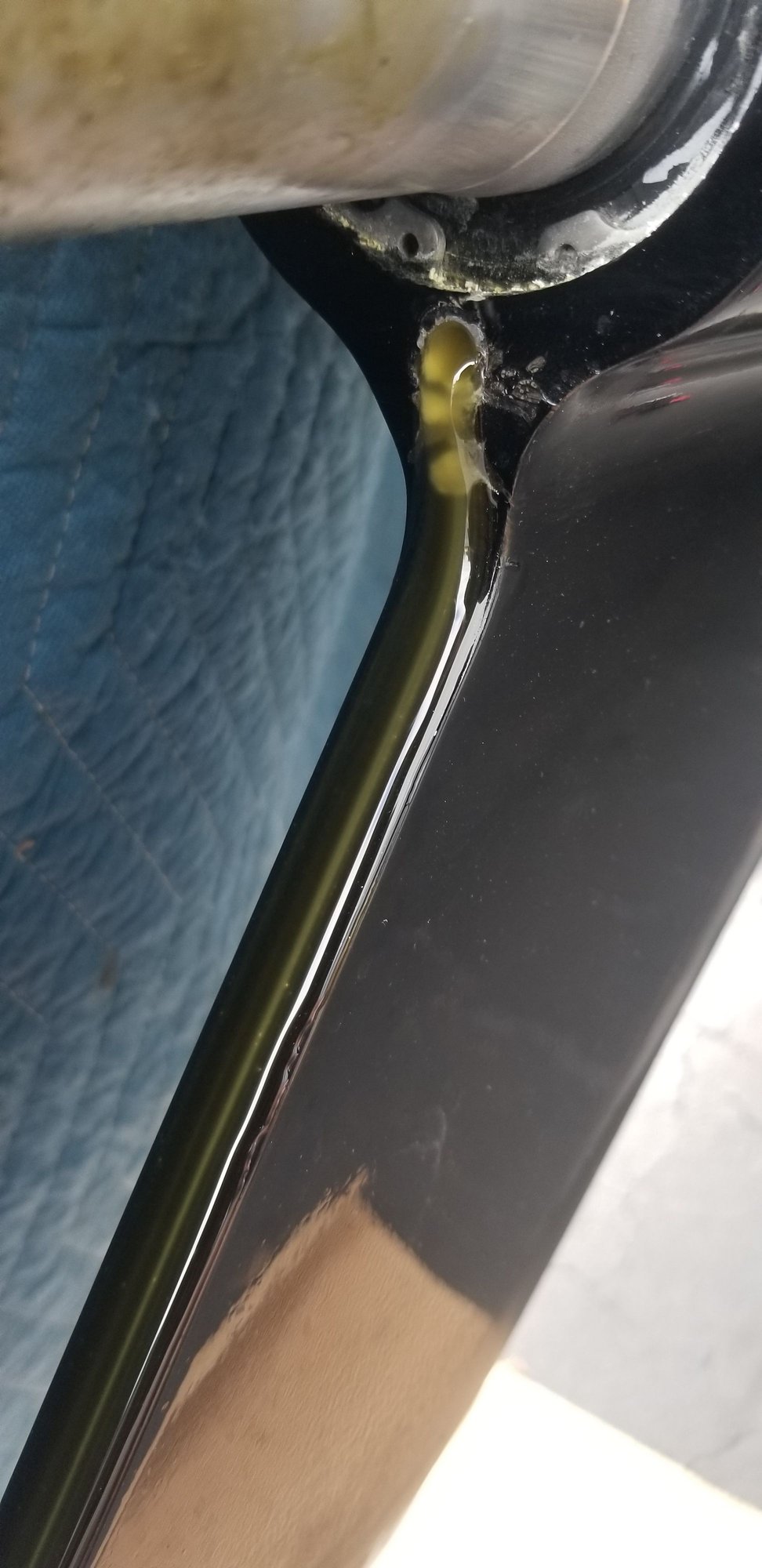

Now as for the lower shaft seals, below is my reasoning on those.. The only cavity that had good looking oil, the prop shaft bearing.. Port drive was 95% clear, while Stbd was milky. Which brings up a whole new question, how the heck did that happen when I was told these have a small pass through hole into the main cavity.. Got me, but here it is. Reservoir cavity above that prop shaft was a milkshake..

First, the seams were all painted over while drives were off replacing the upper gearbox hardware. And I just touched the nicks along those lines up again last week. So we will see I guess.

Second, they were recently opened up by Weismann, the O-rings replaced, and properly torqued, one would hope. No leaks on any of the bolts, so we gotta assume that is all good. Plus at speed, there is less than a inch of the whole lower case in the water. When I checked them directly after a couple runs, oil looks good. Let em set in the water for 24hrs, light trace of water. 72hrs, milkshakes..

Third, and a good point I spoke about with best drive guy I know today. These lowers are atmospheric vented above the waterline into the upper case. They can't pull a vacuum, any more than they could build up pressure. That vent port is what I used to pressure test on today.

Now all that said, the braided vent tube is a possible source of leaks, I've never pressure tested that old line. Tomorrow when I pull the bellows back to check things, I'm gonna yank those lines off and check just to be sure.

Now as for the lower shaft seals, below is my reasoning on those.. The only cavity that had good looking oil, the prop shaft bearing.. Port drive was 95% clear, while Stbd was milky. Which brings up a whole new question, how the heck did that happen when I was told these have a small pass through hole into the main cavity.. Got me, but here it is. Reservoir cavity above that prop shaft was a milkshake..

The following users liked this post:

Twin O/B Sonic (02-23-2021)

#1087

Registered

Thread Starter

New CP3 onboard and after a few more hours tinkering, should be about ready to fire up again. Spent the day flushing lower units with diesel fuel. Pressure and vacuum tested those vent tubes, and they are not the source. Guess I owe everyone a beer...

Thinking it's time to call in David Copperfield to explain this magic trick. Popped both bellows loose and while there was a little oily water in them, it's hard to say if that's where the water got in. Now that we vented the bellows into the upper gear box, it's not possible to pressurize them. But the U-Joints showed no sign of salt water intrusion as they did on last tear down. And when gear oil gets contaminated with water, it foams.

So chicken or egg question. While that's the only area I could hear air escaping thru, it could just be passing around the yoke spines and not the our yoke seal. So same goes with the oily residue. Was it foaming that just boiled over via the shaft splines..

I think these drives would be perfect for a fast shootout setup. Drop boat in, make a pass, put boat back on trailer. Problem solved..

Thinking it's time to call in David Copperfield to explain this magic trick. Popped both bellows loose and while there was a little oily water in them, it's hard to say if that's where the water got in. Now that we vented the bellows into the upper gear box, it's not possible to pressurize them. But the U-Joints showed no sign of salt water intrusion as they did on last tear down. And when gear oil gets contaminated with water, it foams.

So chicken or egg question. While that's the only area I could hear air escaping thru, it could just be passing around the yoke spines and not the our yoke seal. So same goes with the oily residue. Was it foaming that just boiled over via the shaft splines..

I think these drives would be perfect for a fast shootout setup. Drop boat in, make a pass, put boat back on trailer. Problem solved..

The following 2 users liked this post by kidturbo:

2187 (02-25-2021), Gimme Fuel (02-25-2021)

#1088

Gold Member

I can source a couple of locally made drives if it helps. ($400 each) Theyíre really made for outboard setup but Iím sure you could adapt them somehow.

Been following from the start and the problems youíve solved are so far out of my league, itís mind blowing. Iím sure youíll get this beast running right, with or without the current drives and I really look forward to seeing a picture of it running Sydney Harbor. You and Dave must be two of the most persistent and patient people on Earth.

Thanks so much for the education and the entertainment.

RR.

Been following from the start and the problems youíve solved are so far out of my league, itís mind blowing. Iím sure youíll get this beast running right, with or without the current drives and I really look forward to seeing a picture of it running Sydney Harbor. You and Dave must be two of the most persistent and patient people on Earth.

Thanks so much for the education and the entertainment.

RR.

The following 5 users liked this post by rak rua:

2187 (02-25-2021), Gimme Fuel (02-25-2021), kidturbo (02-25-2021), payuppsucker (02-25-2021), Twin O/B Sonic (02-25-2021)

#1089

Registered

That’s a pretty serious pair of drives......at least 1,000hp each. Surely?

The following 5 users liked this post by 2187:

Gimme Fuel (02-25-2021), kidturbo (02-25-2021), payuppsucker (02-25-2021), rak rua (02-25-2021), Twin O/B Sonic (02-25-2021)

#1090

Registered

Join Date: Aug 2012

Location: Collierville, TN and Pickwick Lake

Posts: 2,291

Received 395 Likes

on

165 Posts

ďThe only cavity that had good looking oil, the prop shaft bearing.. Port drive was 95% clear, while Stbd was milky. Which brings up a whole new question, how the heck did that happen when I was told these have a small pass through hole into the main cavity.. Got me, but here it is. Reservoir cavity above that prop shaft was a milkshakeĒ

If Iím understanding you correctly maybe the pass through hole is nonexistent or clogged and the propshaft bearing cavity is building pressure and allowing a vacuum when cooled.

If Iím understanding you correctly maybe the pass through hole is nonexistent or clogged and the propshaft bearing cavity is building pressure and allowing a vacuum when cooled.