40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#1291

Registered

Holy crap, i haven't seen this thread in 2 months ! Since the diamond plate was cut and box welding was getting started.

everything looks awesome, looking forward to see and hear how you solved the alignment and shaft angles.

october sea trials maybe ?

everything looks awesome, looking forward to see and hear how you solved the alignment and shaft angles.

october sea trials maybe ?

The following users liked this post:

kidturbo (09-22-2021)

#1293

Registered

Thread Starter

Plan is get em on the boat next week, float check for leaks, then cut the driveshafts and done. So first half of October is looking good.

The following 3 users liked this post by kidturbo:

#1295

Gold Member

I’d like to modify one into a wall safe……

Could you please powder coat one gold. 🙂

Could you please powder coat one gold. 🙂

#1296

Registered

Thread Starter

Our new target holders are fresh out of powdercoat.. Took a little extra time [like when the powerdercoat guy sends them back to ya after sand blasting], but they are officially ready to hang paper next week.

Heavy little suckers too..

Heavy little suckers too..

The following 5 users liked this post by kidturbo:

2187 (10-16-2021), Gimme Fuel (10-18-2021), hoodoo (10-17-2021), pasquesi (10-17-2021), rak rua (10-16-2021)

#1297

Registered

Thread Starter

New studs are in, tee bushings added to help protect the powedercoating, and transom assemblies are torqued to the extension boxes. Pretty happy with all the outside lines. Always find little things I would do differently next time. Tomorrow we'll see how well all that math works out..

Last edited by kidturbo; 10-20-2021 at 10:30 PM.

The following 6 users liked this post by kidturbo:

2187 (10-21-2021), Gimme Fuel (10-21-2021), IGetWet (10-21-2021), ksalmine (10-21-2021), outonsafari (10-21-2021), payuppsucker (10-20-2021)

#1298

Registered

Thread Starter

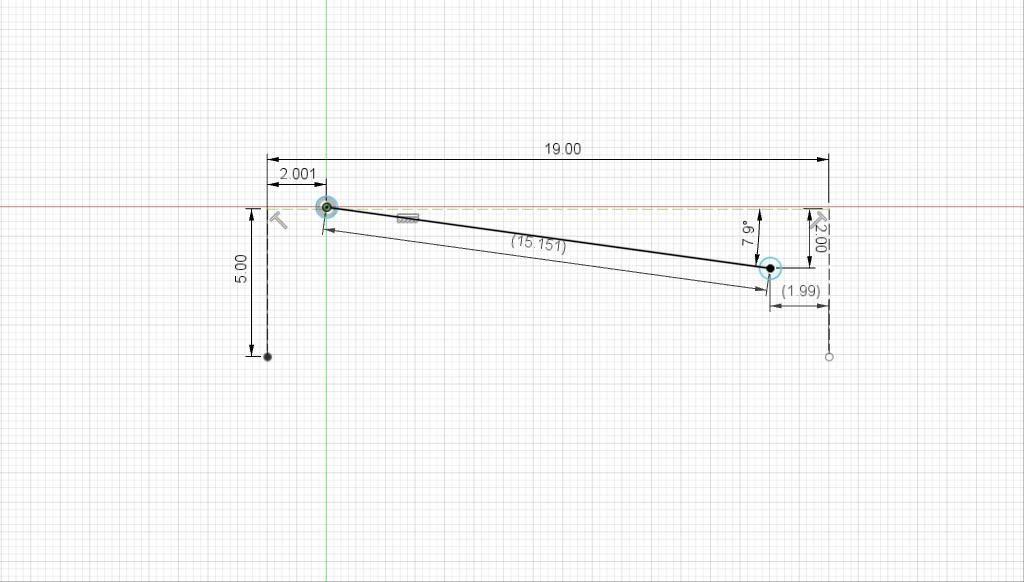

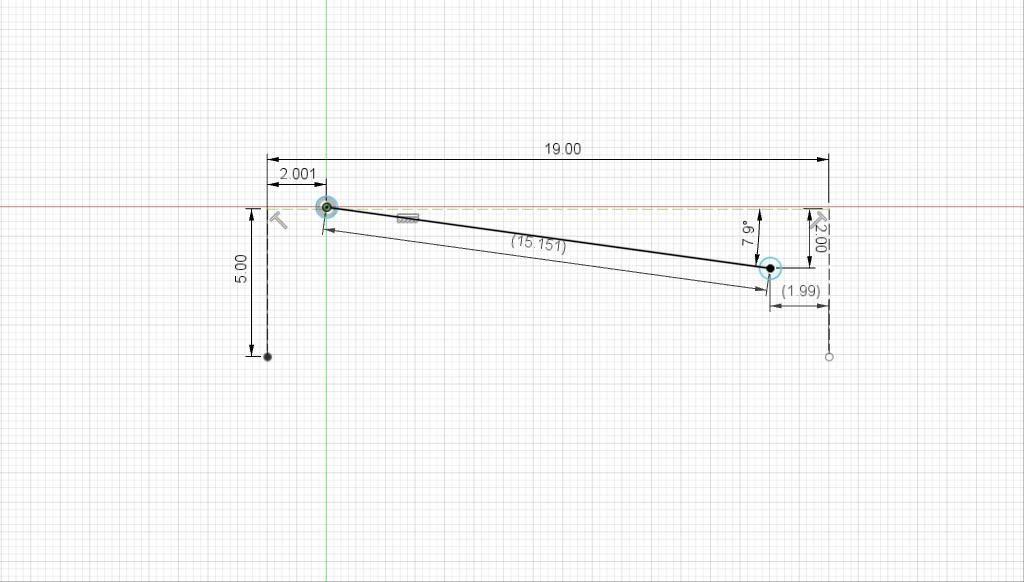

Can't believe it, so far **** actually matches up to what I scratched out on paper several months ago. All the math relating to the driveline side appears to be pretty spot on so far. Transom carrier bearing flange faces are within 0.3deg of the transmission flanges. Driveshaft length is gonna land at about 18.5". I had estimated 19"on that below.

Two unknowns left to verify now. Actual driveshaft angle at current height, which I had estimated at 7.9deg, and the final prop shaft height. Since we sold the old drives, that's now gonna be a good start from scratch guesstimate again. Those marks I'd placed on the transom during mock up are long gone now. But my Lake X setup guru grabbed a tape measure and gave me the old "I think your good" comment on the way out the door today. Would sure be nice to drop these boxes 3/4" to the top hole if we can, but I don't believe our short driveshafts are gonna allow for it. Either way, still have 1" extra shim range if need be.

Making some progress again at least. Plus it feels good knowing Dave and I are not going into the custom marine furniture business any time soon...

Two unknowns left to verify now. Actual driveshaft angle at current height, which I had estimated at 7.9deg, and the final prop shaft height. Since we sold the old drives, that's now gonna be a good start from scratch guesstimate again. Those marks I'd placed on the transom during mock up are long gone now. But my Lake X setup guru grabbed a tape measure and gave me the old "I think your good" comment on the way out the door today. Would sure be nice to drop these boxes 3/4" to the top hole if we can, but I don't believe our short driveshafts are gonna allow for it. Either way, still have 1" extra shim range if need be.

Making some progress again at least. Plus it feels good knowing Dave and I are not going into the custom marine furniture business any time soon...

The following 10 users liked this post by kidturbo:

2187 (10-23-2021), DallasBAJA (10-22-2021), Gimme Fuel (10-22-2021), Knot 4 Me (10-22-2021), ksalmine (10-22-2021), outonsafari (10-21-2021), pasquesi (10-22-2021), payuppsucker (10-21-2021), Rookie (10-21-2021), underpsi68 (10-22-2021)

#1300

Registered

Thread Starter

Spotted this in transmission room last week and had to share a pic. For those wondering, it's insides of a single speed ZF model with 8deg output shaft I believe.

What caught my eye was how they cut the helical gears to mesh at that output angle. Even after spinning the shaft, still doesn't fully register. Not your typical ring and pinion combo.. Sure opened my eyes to how elegantly simple and compact gears can be used to slightly change a shaft angle.

What caught my eye was how they cut the helical gears to mesh at that output angle. Even after spinning the shaft, still doesn't fully register. Not your typical ring and pinion combo.. Sure opened my eyes to how elegantly simple and compact gears can be used to slightly change a shaft angle.

Last edited by kidturbo; 10-22-2021 at 05:23 PM.

The following 2 users liked this post by kidturbo:

2187 (10-23-2021), Gimme Fuel (10-25-2021)