40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#1301

Registered

Most zf transmissions are availed with the “A” for down angle. Same trans available as a straight drop, or angled output flange. Used mainly in shaft boats with engine room ceiling height constraints

#1302

Registered

Thread Starter

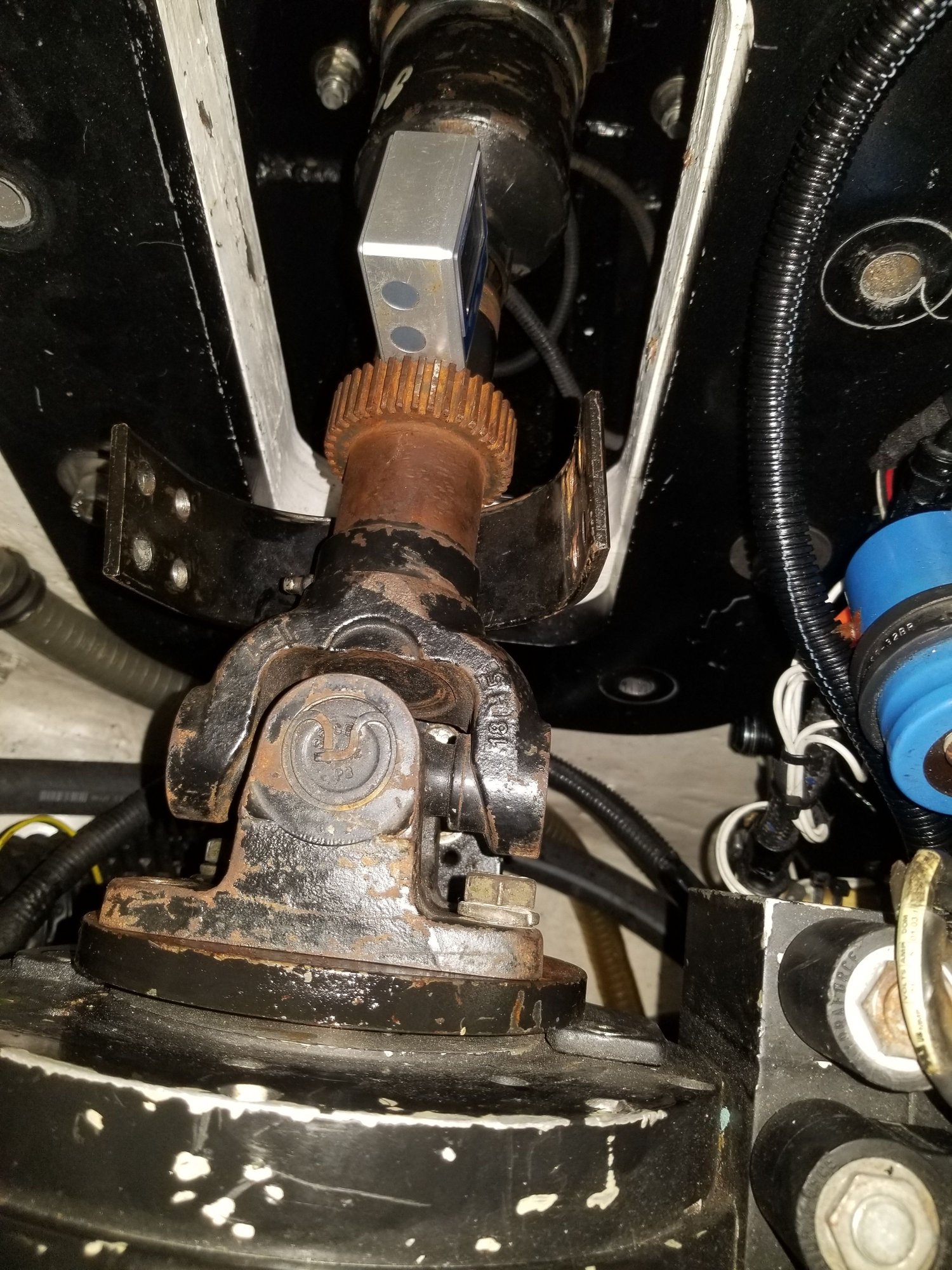

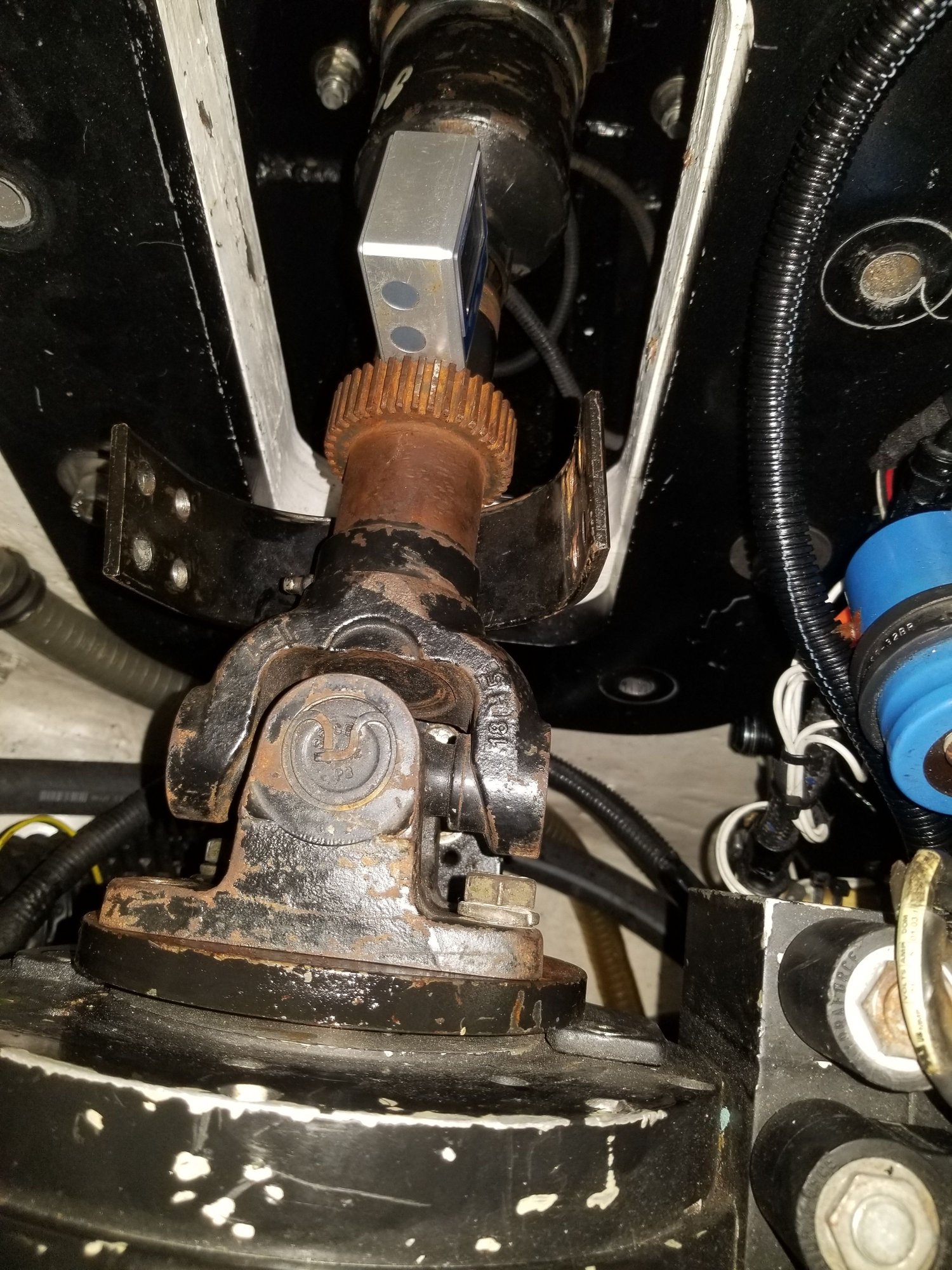

Well it seems all that brain straining math wasn't worth the ink and paper when it came to estimating our driveshaft angle. I missed the mark by about 6deg or 40% off the goal...

Somewhere we lost 1.5" in height on the transom assembly carrier bearing position. And likely on the propshaft estimates also. The goal was to land 2" lower than the transmission flange. And it's actually 3.5" , which jacked the shaft angle up to over 13deg rather than the under 8deg I was shooting for. While we added that 3/8" spacer strip to the bottom edge of transom plates to line up the struts, that still leaves over an inch to account for. Guess I'm gonna have to waterjet some 1" Styrofoam board using same files and mock it all up again to see how things got off track. I could possibly re-drill the transom plates and gain another 3/4" max. Or as one buddy suggested, worst case we re-drill the 8 transom bolt holes to raise it were things need. to be.. Luckily we also mocked up the drives using the 2" spacer in the lowers, so feel confident prop height is still landing in correct range if driveshafts play nice.

After deep discussion with the guy who cut the driveshafts down for us, and a couple of my boat racing buddies, the consensus was, Send It.. When you look at it mocked up, it's not pretty. But saving grace is our mounting flange faces are about dead nuts identical. That along with the fact Spicer 1410 U-Joints [ now we have matching flanges on both ends ] list a 22 or 37 deg maximum angle depending where you read, might actually save the day. Everyone says 13 isn't a terrible number, and shouldn't vibrate or wear out the joints to prematurely. Time will tell..

Here's a few pics of what it looks like. What ya think?

Somewhere we lost 1.5" in height on the transom assembly carrier bearing position. And likely on the propshaft estimates also. The goal was to land 2" lower than the transmission flange. And it's actually 3.5" , which jacked the shaft angle up to over 13deg rather than the under 8deg I was shooting for. While we added that 3/8" spacer strip to the bottom edge of transom plates to line up the struts, that still leaves over an inch to account for. Guess I'm gonna have to waterjet some 1" Styrofoam board using same files and mock it all up again to see how things got off track. I could possibly re-drill the transom plates and gain another 3/4" max. Or as one buddy suggested, worst case we re-drill the 8 transom bolt holes to raise it were things need. to be.. Luckily we also mocked up the drives using the 2" spacer in the lowers, so feel confident prop height is still landing in correct range if driveshafts play nice.

After deep discussion with the guy who cut the driveshafts down for us, and a couple of my boat racing buddies, the consensus was, Send It.. When you look at it mocked up, it's not pretty. But saving grace is our mounting flange faces are about dead nuts identical. That along with the fact Spicer 1410 U-Joints [ now we have matching flanges on both ends ] list a 22 or 37 deg maximum angle depending where you read, might actually save the day. Everyone says 13 isn't a terrible number, and shouldn't vibrate or wear out the joints to prematurely. Time will tell..

Here's a few pics of what it looks like. What ya think?

The following users liked this post:

2187 (11-05-2021)

#1303

Registered

Sorry to hear this Ken... I would drill new mounting holes in the boxes where it needs to be now even if you don't use them you could always change to them if things aren't happy...

Keep in mind in an onroad truck application they can be spinning 3000 rpm and suspension working up and down 5-6 inches ---- maybe not with your torque tho!

Keep in mind in an onroad truck application they can be spinning 3000 rpm and suspension working up and down 5-6 inches ---- maybe not with your torque tho!

#1304

Registered

Thread Starter

I'm not certain there is enough meat in the boxes to get the bottom two bolt holes 3/4" lower than where we are now. But its certainly under consideration...

#1305

Registered

what about an extension piece just on the bottom of the box ? (Like a nailer fin on a new construcion widow)

same thickness as box, by same width as box, by 2 inches, just for the lower holes so it could be raised.

or, isn't the mounting surface of the box 1/2 inch aluminum ? What about a helicoil and stud for the 2 lower bolts ?

the pull is on the top of the transom assy/box, doubt helicoil would fail as that part of the transom assy/box is being pushed.

i'm not second guessing the pro builders or racers when they say 13 will be good, my thinking comes from a save the parts mentality so they don't have to be re produced re bought and re rigged.

#1306

Registered

I sure have run a LOT more angle than that on driveshafts in trucks.

LOTS more in my shorter wheelbase lifted Broncos.

I know not apples to apples, but if the angle is your only concern, I would certainly give it a shot before re-engineering all of that.

If angle does show itself to be an issue and you have room, could add a double Cardan u-joint.

Shortening the shafts would seem like less work.

LOTS more in my shorter wheelbase lifted Broncos.

I know not apples to apples, but if the angle is your only concern, I would certainly give it a shot before re-engineering all of that.

If angle does show itself to be an issue and you have room, could add a double Cardan u-joint.

Shortening the shafts would seem like less work.

The following 3 users liked this post by Keith Atlanta:

#1308

Registered

Thread Starter

The following 2 users liked this post by kidturbo:

2187 (11-06-2021), Gimme Fuel (11-08-2021)

#1309

Registered

Thread Starter

As for our driveshaft options, I have at least 5 professional inputs of "Send It" now to back up my plans. Since vibration is not likely gonna be an issue, U-Joint wear is only concern. And we can switch to a greasable torrington bearing style U- joint if they do wear to quick.

Jacking the box up another inch right now just isn't worth the effort till we know if any problem exists. And then we'd just punch 8 new bolt holes through the transom if need be. Push some wood pins in the old ones. It's just a Baja, not a half mill carbon composite laid up OuterLimits hull.. Plus we run a gasket rather than a Oring.. So long as the box covers the bolt holes, it's gonna seal up fine. But plan is avoid that if at all possible.

This weeks tweak is the trim line extensions. Seems the -4AN trim extension / adapter lines we made up for the W's don't adapt well back to a #6 layout.. But I did try it just to be sure. Exactly 1 RCH from fitting...

Jacking the box up another inch right now just isn't worth the effort till we know if any problem exists. And then we'd just punch 8 new bolt holes through the transom if need be. Push some wood pins in the old ones. It's just a Baja, not a half mill carbon composite laid up OuterLimits hull.. Plus we run a gasket rather than a Oring.. So long as the box covers the bolt holes, it's gonna seal up fine. But plan is avoid that if at all possible.

This weeks tweak is the trim line extensions. Seems the -4AN trim extension / adapter lines we made up for the W's don't adapt well back to a #6 layout.. But I did try it just to be sure. Exactly 1 RCH from fitting...

The following 2 users liked this post by kidturbo:

2187 (11-07-2021), Gimme Fuel (11-08-2021)

#1310

Registered

First thought is you really need to be about 1-3deg....7-8 max. You have come this far and its worth it to do it "right". But then I think shoot you have been doing everything "right" all along and where did it get you! I feel for you man so I vote SEND IT! But I cant look at that last angle pic again or I might change my mind

The following users liked this post:

kidturbo (11-18-2021)