40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#191

Registered

Thread Starter

We switched to the second engine last week and resolved the misfire issue holding us below 3600R. We also removed the scroll block off plates to see how these turbos would act above that rpm. While they made 690hp and 1150ft-lbs uncorrected, these turbos were setting against the surge line at 4200R, making only 30lbs boost opened up. Torque also started dropping off sharply at above 3900. We added some extra fuel and timing, but the turbos just refused to spin any faster. While I don't have the maps, we could tell they were operating in the lower half.

So the spool valve option doesn't look very promising now, cause they would never be opened. Only options are to run these on a single scroll all the time, which might yield us 45psi and probably land us in mid 700hp range. Or test with a big single that we have data on producing 1050hp and 55psi around 3600rpm. We have a couple different S475 models lined to test next week. These units map up to 4.5bar. Really hate to scrap these beautiful twins, but the only other symmetrical pair I can find with smaller turbine housings, still only maps to 3.5bar. So while those would likely work great on a 700hp V8 diesel, we don't think they will get us close to our goals without running in a triple setup. And that's just to many unknowns for a twin engine boat.

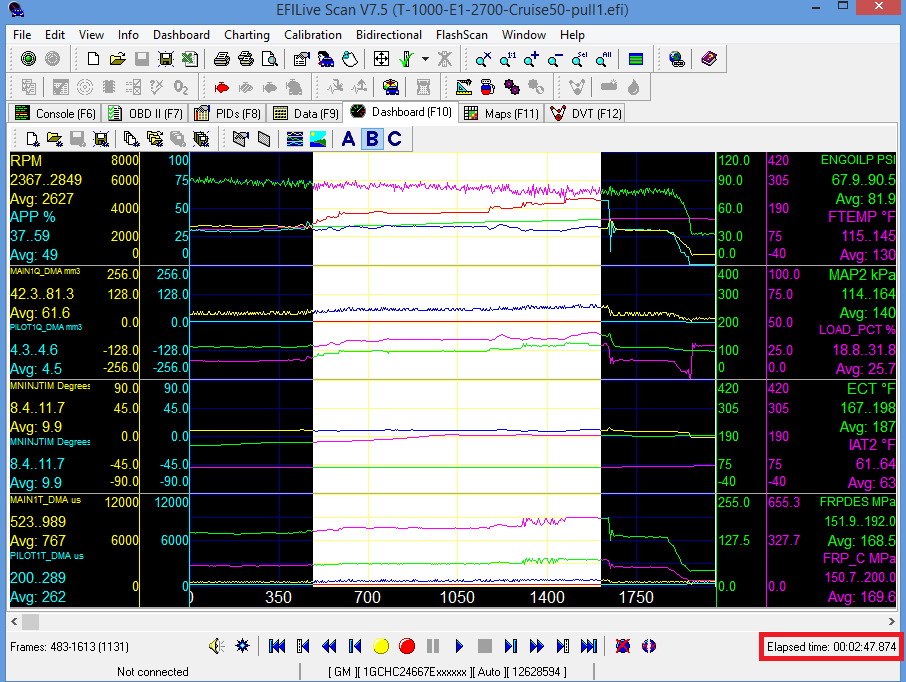

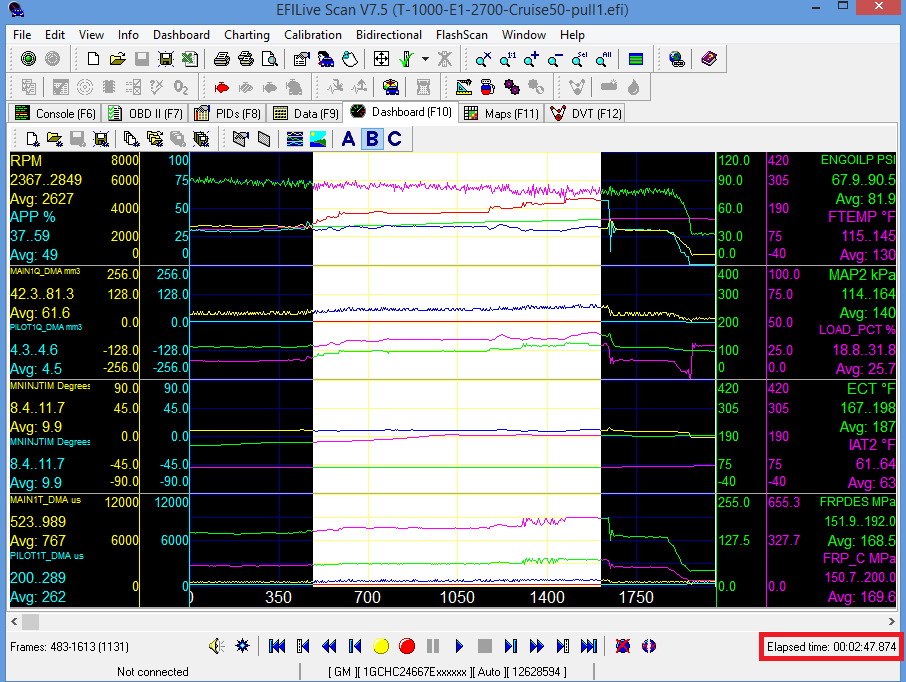

We did manage to validate all the other systems on both engines. Cooling systems components look like they should be sufficient. The seawater pump is making about 10-15psi on the big coolers, while sucking through -20AN lines, and returning into a 12' head height tank. Charge cooler air never touched 110F, and the electric circulation pumps kept things under 210F even while fully loaded at 3400R for over 22 seconds. First pull on this engine was a loaded 50% throttle run lasting almost 3 minutes. See pics below.

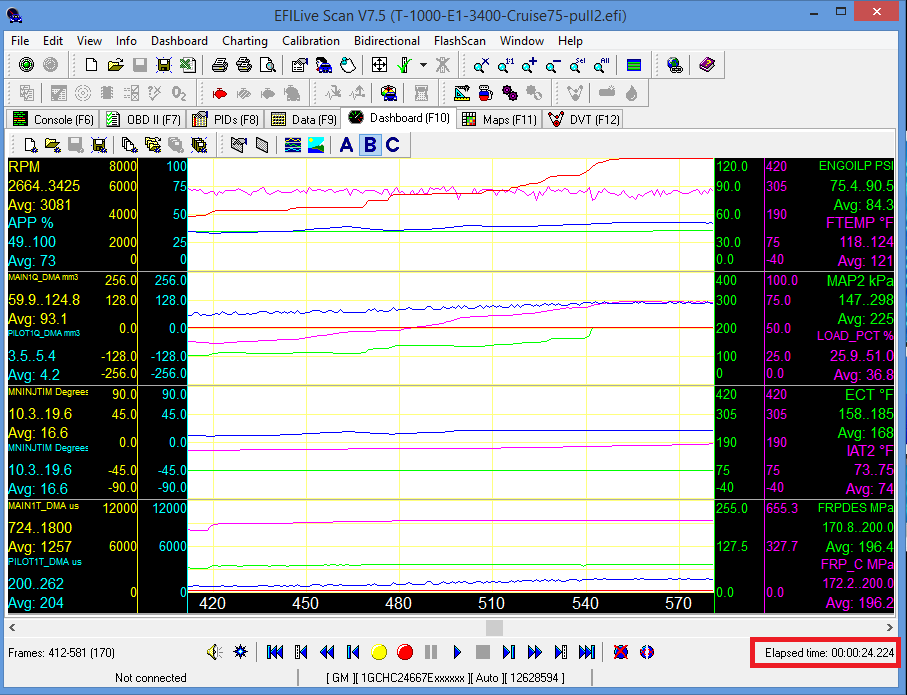

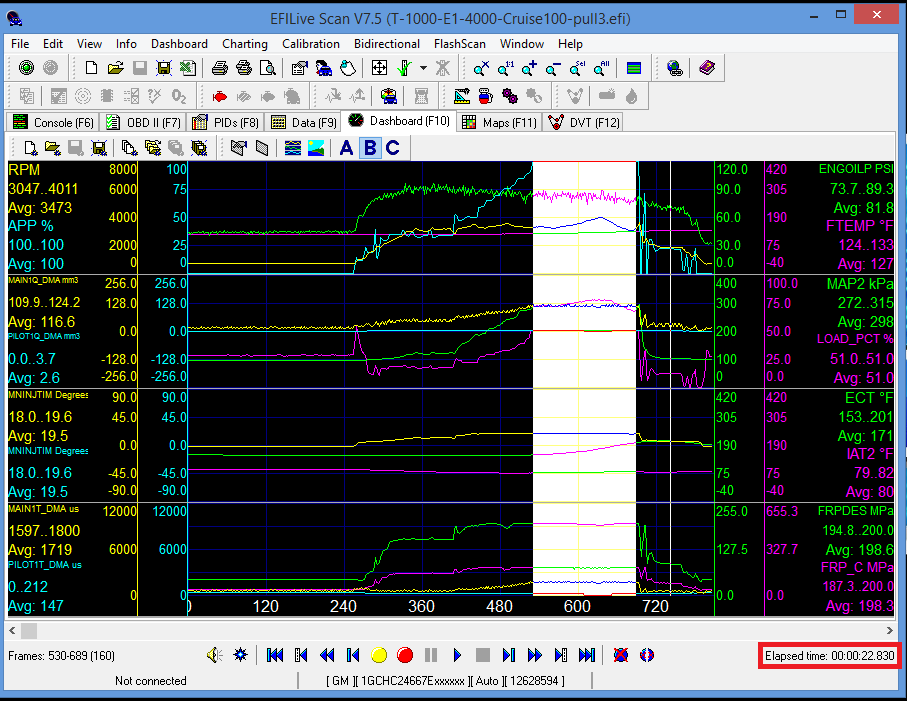

Run times for highlighted ares are bottom right, outlined in red. FTEMP is Oil Temp, and MAP2 equals total boost including 99kpa atmosphere at the dyno site. IAT2 is charged air temp.

So the spool valve option doesn't look very promising now, cause they would never be opened. Only options are to run these on a single scroll all the time, which might yield us 45psi and probably land us in mid 700hp range. Or test with a big single that we have data on producing 1050hp and 55psi around 3600rpm. We have a couple different S475 models lined to test next week. These units map up to 4.5bar. Really hate to scrap these beautiful twins, but the only other symmetrical pair I can find with smaller turbine housings, still only maps to 3.5bar. So while those would likely work great on a 700hp V8 diesel, we don't think they will get us close to our goals without running in a triple setup. And that's just to many unknowns for a twin engine boat.

We did manage to validate all the other systems on both engines. Cooling systems components look like they should be sufficient. The seawater pump is making about 10-15psi on the big coolers, while sucking through -20AN lines, and returning into a 12' head height tank. Charge cooler air never touched 110F, and the electric circulation pumps kept things under 210F even while fully loaded at 3400R for over 22 seconds. First pull on this engine was a loaded 50% throttle run lasting almost 3 minutes. See pics below.

Run times for highlighted ares are bottom right, outlined in red. FTEMP is Oil Temp, and MAP2 equals total boost including 99kpa atmosphere at the dyno site. IAT2 is charged air temp.

#192

Registered

Thread Starter

Funny thing occurred on startup of second engine. A V-band between right side manifold and up-pipe started dripping water. We removed the clamp, separated the up pipe and started the engine. Within in a minute water started spraying out of the manifold. Ah crap, we have a leak.. So we pressure tested every tube to 60psi, but couldn't find any leaks...

After an hour of checking pipes, we broke out the IR camera and started shooting temps. Well there's your problem... The last couple night temps dropped down to freezing in the Indi area. Our 1100 gallons of seawater setting outside seems to have chilled down a bit. I just started laughing, until my buddy Mark said "what's so dang funny?" The headers are so cold, they started condensation at idle and making water inside the tubes, so both of us thought they were leaking..

We continued on with our test runs, and problem quickly went away once we heated that 1100 gallons of water up to around 65F. But it sure had us scratching our heads for over an hour.

After an hour of checking pipes, we broke out the IR camera and started shooting temps. Well there's your problem... The last couple night temps dropped down to freezing in the Indi area. Our 1100 gallons of seawater setting outside seems to have chilled down a bit. I just started laughing, until my buddy Mark said "what's so dang funny?" The headers are so cold, they started condensation at idle and making water inside the tubes, so both of us thought they were leaking..

We continued on with our test runs, and problem quickly went away once we heated that 1100 gallons of water up to around 65F. But it sure had us scratching our heads for over an hour.

Last edited by kidturbo; 10-21-2018 at 01:12 AM.

#193

Registered

Thread Starter

#195

Registered

Thread Starter

So now dyno testing is done, he's the final numbers. While they certainly look killer, the NRE 61mm twins are not making the cut on this build.

The sequential turbo setup showed good potential, up to about 750hp. Which could easily be done by a pair of 58mm units. So one would think the 61's would be great at producing power upto 1000hp or more. Which they are, on gasoline or alcohol engines spinning much high RPM, exhaust CFM's, and only ever require 36lbs of boost. Most of the smaller 300 series turbos we examined have a compressor map with a 3 to 3.5bar maximum. While fine for gassers, diesels need Boost...

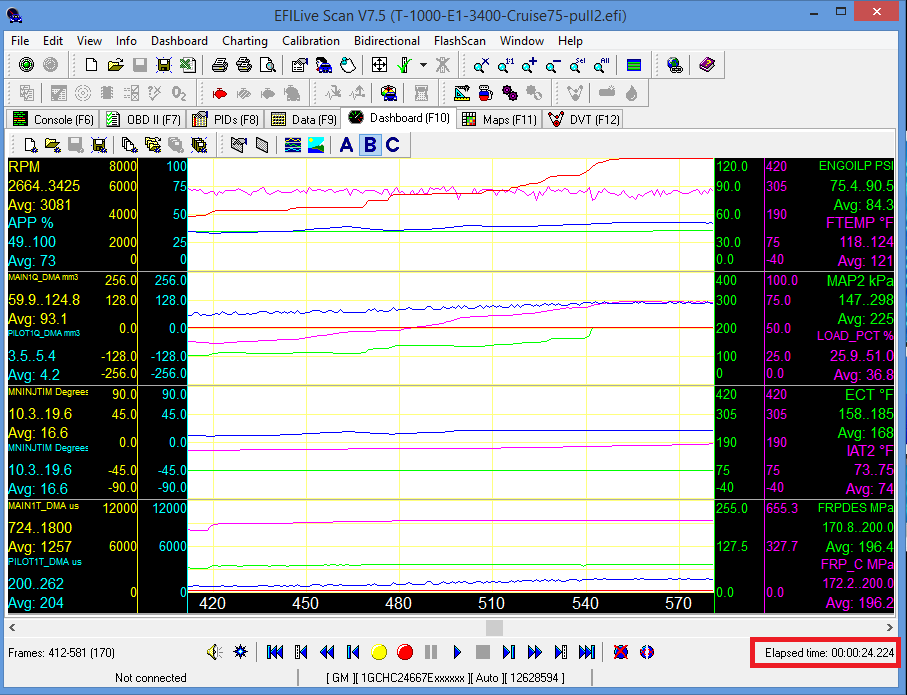

The 61mm sequential pr produced 36lbs of boost and 50psi drive pressure at about 3700r running on a single scroll. Or half the turbine housing, replicating a spool valve setup. Compared to only 27lbs of boost same rpm opened up. Wile testing this setup, we experienced a glitch that kept use from testing above 3800 rpm. But EGT was holding around the 1500F range there. After a dozen pulls or about hour testing [20 gallons of fuel] in that first engine, we decided to put some time on the second engine. Tagged as Engine #1 cause it was built first.

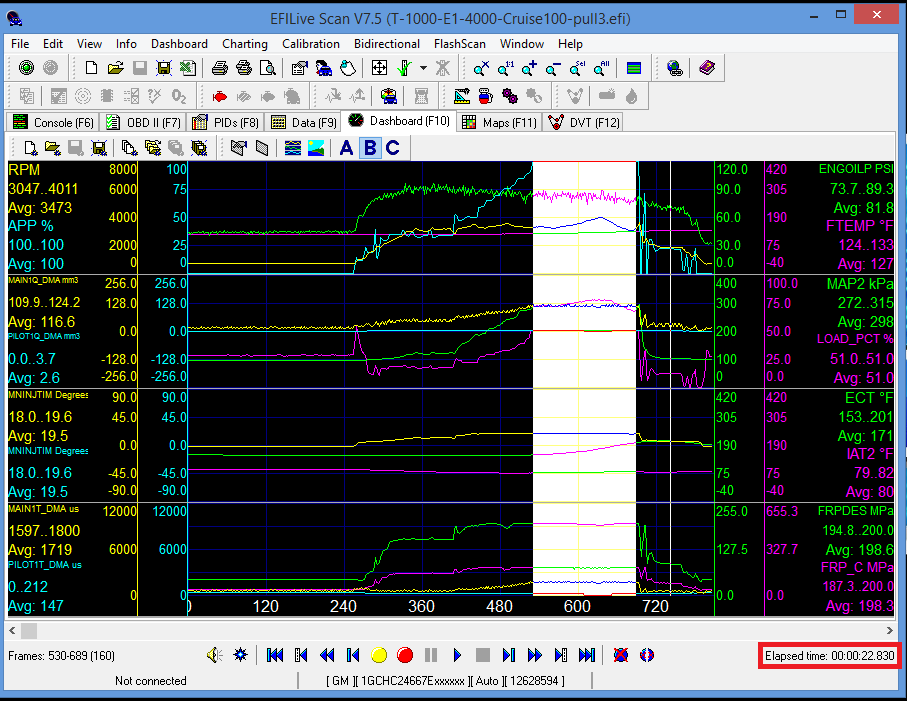

When we bolted up the second engine, we changed the wiring harness to better isolate the cam/crank sensor wires from injector interference. And the misfire issue we logged on first engine went away. We had also decided to leave the turbo scrolls open since we had plenty of data on other setup. So plan was to see if these 61mm's would take off above 4000rpm. Upon first pull to 4200rpm the answer was clear. Turbos hit the surge line around 4100r and then torque and boost started falling off at 4200r. Not yet sure if was the cam or intake killing the torque curve, but the higher we went the faster it dropped off. So it was clear these turbos, even with spool valves, would never make it to 50psi boost. Which is about the minimal requirement to cleanly make 850hp.

Here is best data scroll valves blocked.

The sequential turbo setup showed good potential, up to about 750hp. Which could easily be done by a pair of 58mm units. So one would think the 61's would be great at producing power upto 1000hp or more. Which they are, on gasoline or alcohol engines spinning much high RPM, exhaust CFM's, and only ever require 36lbs of boost. Most of the smaller 300 series turbos we examined have a compressor map with a 3 to 3.5bar maximum. While fine for gassers, diesels need Boost...

The 61mm sequential pr produced 36lbs of boost and 50psi drive pressure at about 3700r running on a single scroll. Or half the turbine housing, replicating a spool valve setup. Compared to only 27lbs of boost same rpm opened up. Wile testing this setup, we experienced a glitch that kept use from testing above 3800 rpm. But EGT was holding around the 1500F range there. After a dozen pulls or about hour testing [20 gallons of fuel] in that first engine, we decided to put some time on the second engine. Tagged as Engine #1 cause it was built first.

When we bolted up the second engine, we changed the wiring harness to better isolate the cam/crank sensor wires from injector interference. And the misfire issue we logged on first engine went away. We had also decided to leave the turbo scrolls open since we had plenty of data on other setup. So plan was to see if these 61mm's would take off above 4000rpm. Upon first pull to 4200rpm the answer was clear. Turbos hit the surge line around 4100r and then torque and boost started falling off at 4200r. Not yet sure if was the cam or intake killing the torque curve, but the higher we went the faster it dropped off. So it was clear these turbos, even with spool valves, would never make it to 50psi boost. Which is about the minimal requirement to cleanly make 850hp.

Here is best data scroll valves blocked.

Last edited by kidturbo; 11-04-2018 at 01:40 AM.

#196

Registered

Thread Starter

Last pull 3000-4200rpm testing twins with scrolls open.

#197

Registered

Thread Starter

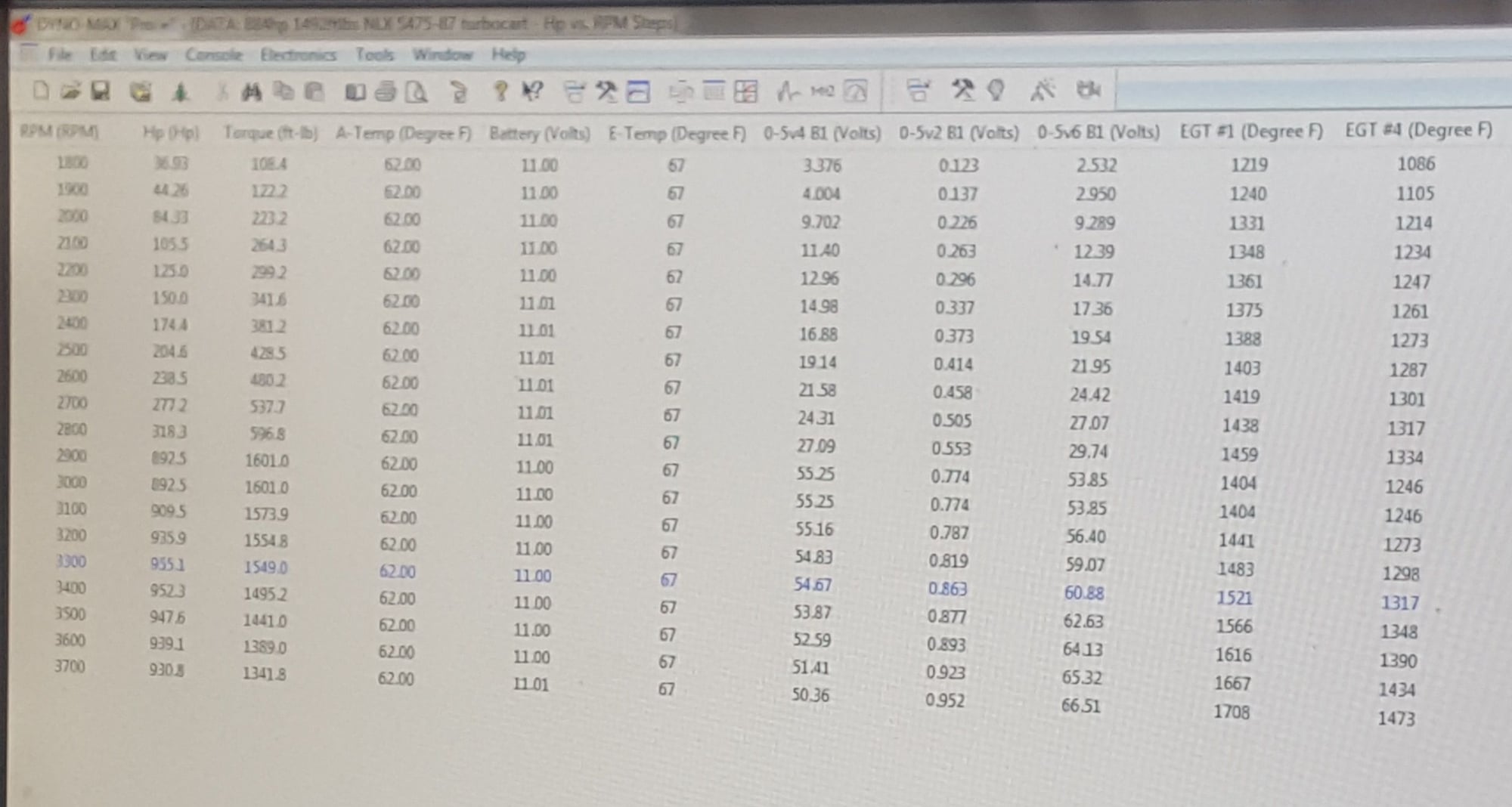

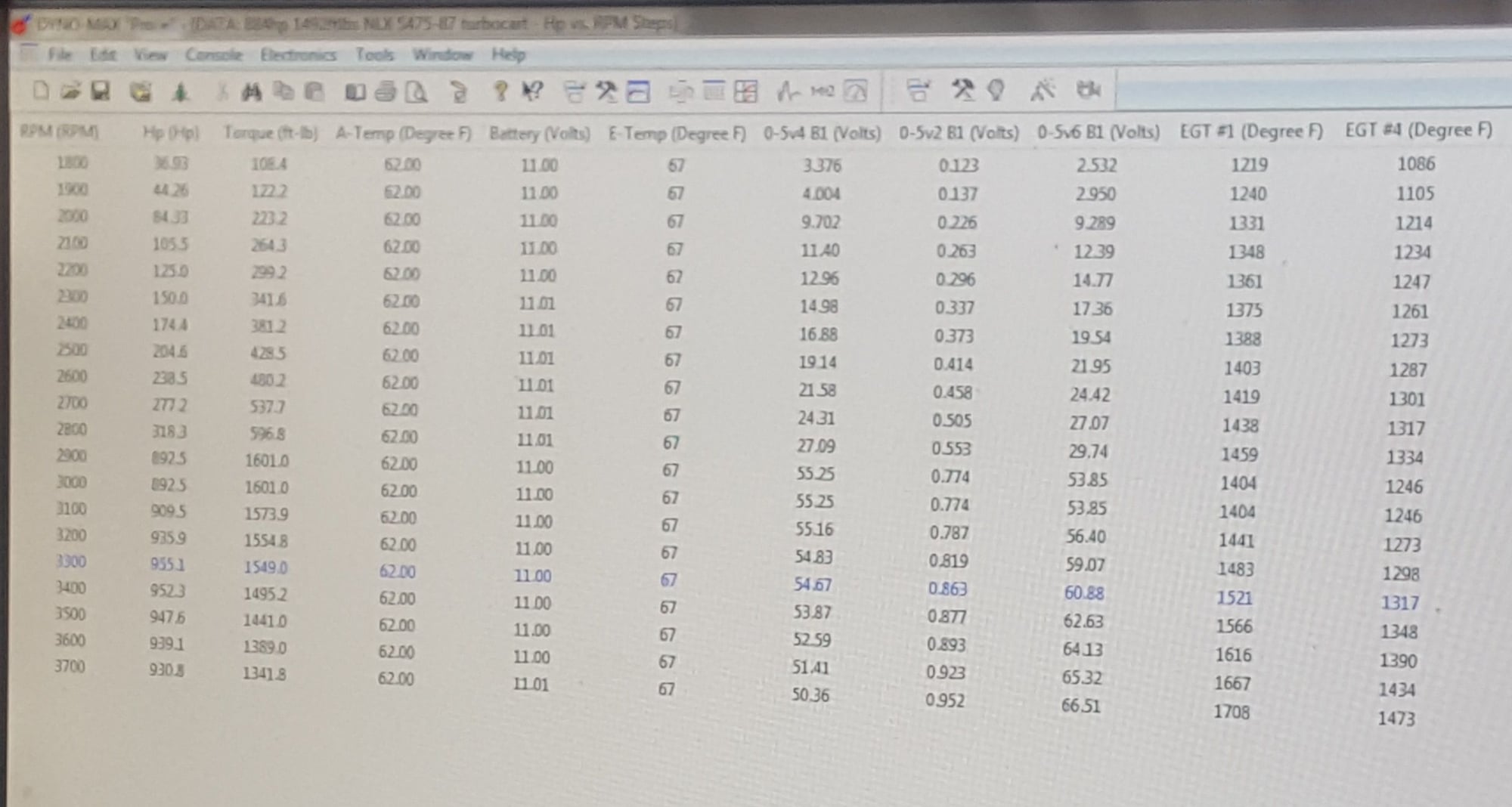

Soon as we switched to the single S475 turbo, things picked up. At 3100rpm, 45psi boost with only 46psi drive pressure, a gain of 9psi compared to best the twins produced. EGT's dropped off to 1000-1200F range, and exhaust stack was much much cleaner even down low. If you look at the first data below, (0-5v4 B1 Volts) is boost pressure, while (0-5v6 B1 Volts) is drive pressure. One between them is crankcase pressure, which was happy to see remaining low.. You can see in the data it was making 2.5psi boost down at 2100rpm with zero load on the engine. The twins didn't make any boost below 2300rpm. So while HP and torque numbers of 718/1191 may not look very impressive, the potential to see 50psi boost was finally there.

#198

Registered

Thread Starter

Since the exhaust flow was extra clean now using previous conservative fueling and timing, we decided to crank em up a bit. That's when this single came into it's own. Adding few hundred us to injector pulsewidth, then bumping timing up another 5 deg, it quickly jumped passed the 50psi boost, 1500ft-lb, and 800hp goal. But EGT's came up there also. Then we chucked a belt off and decided to call it a day. Ended video below.

#199

Registered

Thread Starter

Last, we traded the Borg turbo cartridge in for a Bulleseye NLX-S475-87 off of Mark's triple turbo Duramax street truck setup. Both turbo fit same T6 1.05 AR housing. He's made in excess of 1080hp with a stock S475 and 250% over injectors on the same dyno., This Bullseye version with it's modified wheels and ceramic ball bearings has been tested at over 1200hp. We said since it fits, might as well spin it...

Very impressive unit, which actually picked up an addition 50 hp and almost 100ft-lb torque, Topping the charts at 955hp @ 3200rpm / 1601lb-ft torque at 2900rpm with 56psi boost on 60psi drive pressure. EGT was between 1300-1500F at peak power. So looks like we found our winner. With some slightly larger injectors, we should be good well into the 1100hp / 1750ft-lb range. And to free up the exhaust a bit, we ordered them in a 76mm turbine with slightly better AR. This should also allow for nice operation in a lower 750-800hp keeping the EGT's low. And even though we didn't spend any time testing the singles down there, I'm guessing torque figures at 2600r be pushing 2000ft-lb.

Or at least slightly better than this 12.9L PACCAR MX-13 in my buddies Kenworth..

Very impressive unit, which actually picked up an addition 50 hp and almost 100ft-lb torque, Topping the charts at 955hp @ 3200rpm / 1601lb-ft torque at 2900rpm with 56psi boost on 60psi drive pressure. EGT was between 1300-1500F at peak power. So looks like we found our winner. With some slightly larger injectors, we should be good well into the 1100hp / 1750ft-lb range. And to free up the exhaust a bit, we ordered them in a 76mm turbine with slightly better AR. This should also allow for nice operation in a lower 750-800hp keeping the EGT's low. And even though we didn't spend any time testing the singles down there, I'm guessing torque figures at 2600r be pushing 2000ft-lb.

Or at least slightly better than this 12.9L PACCAR MX-13 in my buddies Kenworth..

Last edited by kidturbo; 11-04-2018 at 04:09 AM.