40' Outlaw Upgrades - Twin 900Sc to 1000hp Duramax Diesels

#401

Registered

That was over a half decade ago, how am I supposed to remember something like that???

Last edited by 302Sport; 08-25-2019 at 12:48 AM.

#402

Registered

Thread Starter

Here is a video of the port side start up without turbo or charge cooler.

Actually pretty clean for 200% over injectors on a cold start.

Actually pretty clean for 200% over injectors on a cold start.

#403

Registered

Thread Starter

#404

Registered

Thread Starter

Ok answered my question and hopefully saved some time not needing to pull and reverse the drive pumps.

A Lycoming T-53 low pressure shaft turns counter-clockwise looking from rear of the engine. That shaft spins a planetary gear reduction box "N2" with an output of clockwise direction looking from the rear. However when installed in a boat, these turbines are set backwards, with hot side discharge facing fwd and the cold side "output shaft" facing the drive, thus spinning same direction as a standard GM crankshaft, counter-clockwise looking from the rear.

If that didn't confuse ya, I repeated all the tests with engine cranking and still get no oil flow. Even pulled input line off the pump and attached a clear line feeding it oil from a elevated height. At 150rpm cranking, with 75/90 synthetic, it barely moves the height of oil in one direction pictured below. But it did consistently lean in the same direction.

Pumps are plumbed right, but are they producing sufficient flow to suck the oil up out of the pan below the gear box? Obviously not at cranking speed, but I started the engine, and at idle, it pumped some oil through the cooler and into a cup I placed inside the extension box. Now the only question is, could the oil viscosity be our issue. I emailed Patrick and basically got "haven't seen any of that hardware since 2004." Leaving me to wonder if the previous issues seen with bearing failures in these cases were due to insufficient oiling, or just from spinning 4500 rpm rated roller bearings 6k plus???

I still find little more than patent details on the pumps. These are a "Roller Vane" design, and not your typical Rotary Vane oil pump. Supposedly they were designed to last longer with less noise. So for now I'm gonna let em roll on, until we can spin up the Rpm's and properly test with some different viscosity oils and some sort of gauge...

A Lycoming T-53 low pressure shaft turns counter-clockwise looking from rear of the engine. That shaft spins a planetary gear reduction box "N2" with an output of clockwise direction looking from the rear. However when installed in a boat, these turbines are set backwards, with hot side discharge facing fwd and the cold side "output shaft" facing the drive, thus spinning same direction as a standard GM crankshaft, counter-clockwise looking from the rear.

If that didn't confuse ya, I repeated all the tests with engine cranking and still get no oil flow. Even pulled input line off the pump and attached a clear line feeding it oil from a elevated height. At 150rpm cranking, with 75/90 synthetic, it barely moves the height of oil in one direction pictured below. But it did consistently lean in the same direction.

Pumps are plumbed right, but are they producing sufficient flow to suck the oil up out of the pan below the gear box? Obviously not at cranking speed, but I started the engine, and at idle, it pumped some oil through the cooler and into a cup I placed inside the extension box. Now the only question is, could the oil viscosity be our issue. I emailed Patrick and basically got "haven't seen any of that hardware since 2004." Leaving me to wonder if the previous issues seen with bearing failures in these cases were due to insufficient oiling, or just from spinning 4500 rpm rated roller bearings 6k plus???

I still find little more than patent details on the pumps. These are a "Roller Vane" design, and not your typical Rotary Vane oil pump. Supposedly they were designed to last longer with less noise. So for now I'm gonna let em roll on, until we can spin up the Rpm's and properly test with some different viscosity oils and some sort of gauge...

#406

Registered

Thread Starter

Good question. Why I ask the builder for further documentation. And back to the internet we go...

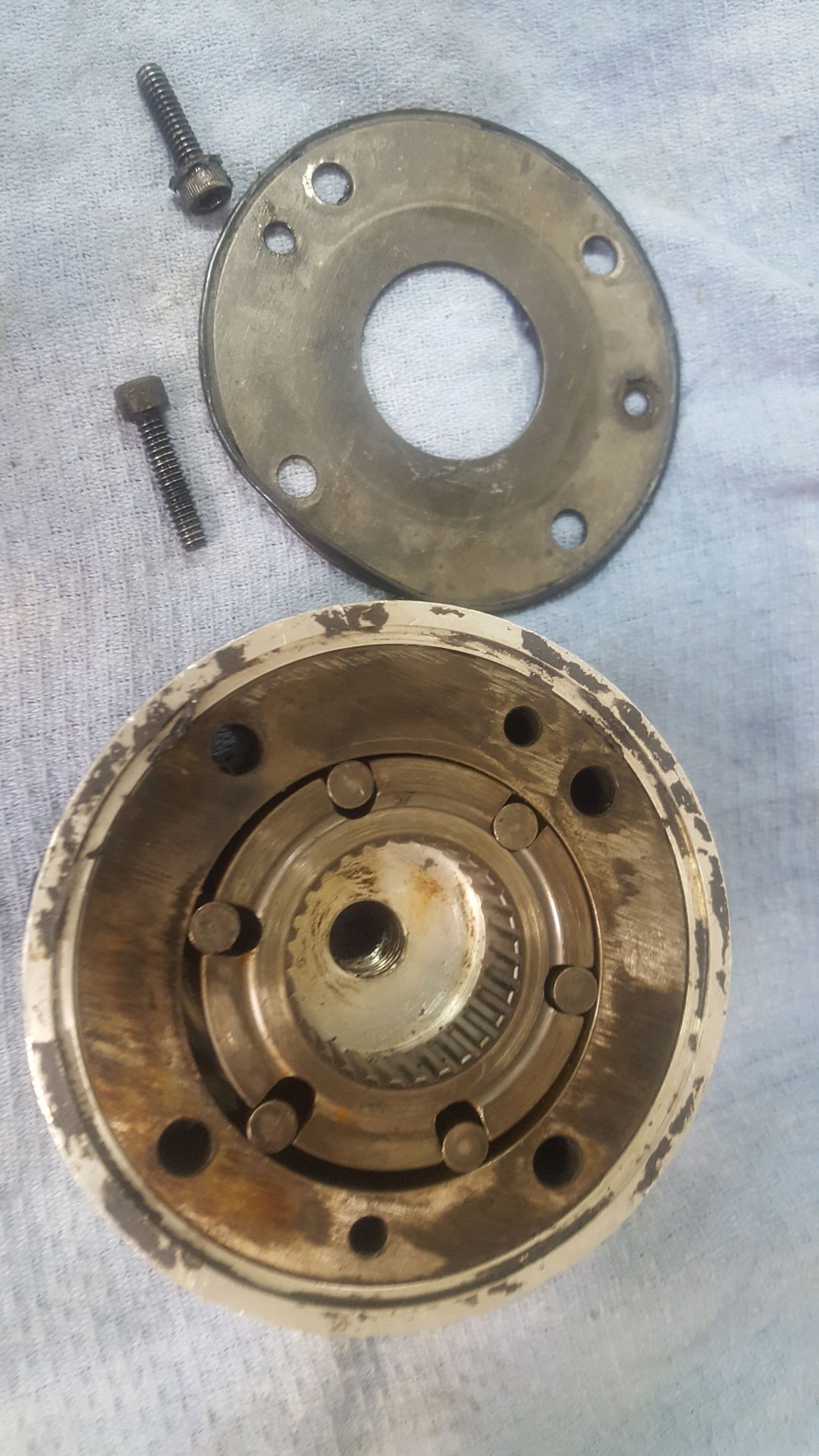

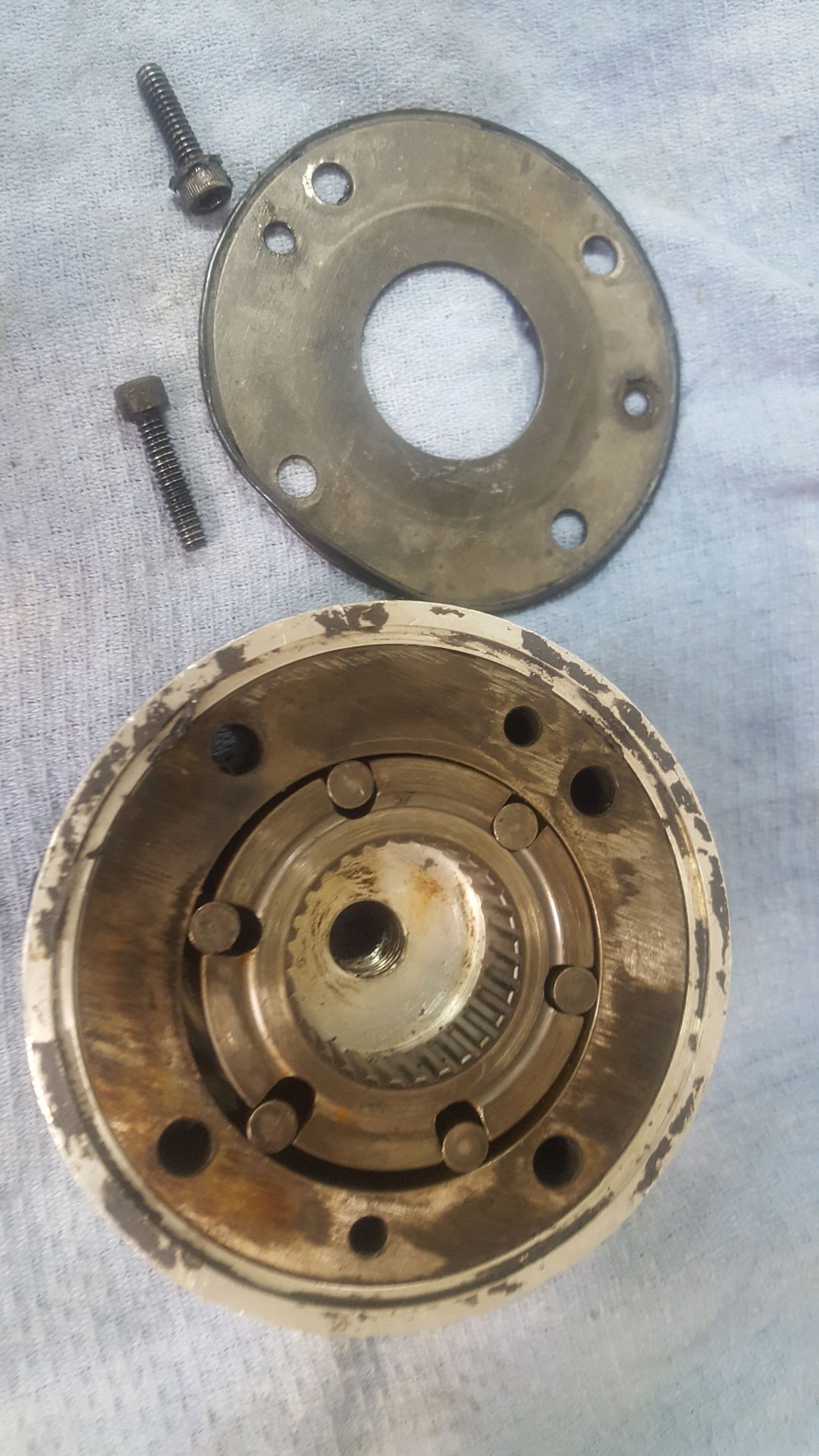

I believe your assumption of low efficiency is probably correct. Certainly at low speeds it seems to be the case. I never inspected these pumps, that was done by the drive shop in Sarasota that swapped the gearset for me and fixed all the leaks. Only have that spare unit pictured I pulled from a box of parts. Nothing replaceable besides the rollers. But these have to suck oil out of the reservoir 3" below the main case to operate in a "Dry Sump" environment.

Speaking with Tyson last night on a transmissions issue, was a simple stuck solenoid valve, and those are now working perfectly in all gears. I brought up these strange pumps. He's not played with em before either, but said the lower gear should sling enough oil up top if I raise the level. Those removing the dry sump feature.

Kinda reminds me of reading about the first guys to dry sump the #6 drives. How much oil is enough to make em live happy but not drag off a bunch of power. Reason I think we'll experiment once the cooling system is installed and I can spin things a bit faster while still on the trailer.

I believe your assumption of low efficiency is probably correct. Certainly at low speeds it seems to be the case. I never inspected these pumps, that was done by the drive shop in Sarasota that swapped the gearset for me and fixed all the leaks. Only have that spare unit pictured I pulled from a box of parts. Nothing replaceable besides the rollers. But these have to suck oil out of the reservoir 3" below the main case to operate in a "Dry Sump" environment.

Speaking with Tyson last night on a transmissions issue, was a simple stuck solenoid valve, and those are now working perfectly in all gears. I brought up these strange pumps. He's not played with em before either, but said the lower gear should sling enough oil up top if I raise the level. Those removing the dry sump feature.

Kinda reminds me of reading about the first guys to dry sump the #6 drives. How much oil is enough to make em live happy but not drag off a bunch of power. Reason I think we'll experiment once the cooling system is installed and I can spin things a bit faster while still on the trailer.

Last edited by kidturbo; 08-28-2019 at 12:52 PM.

#407

Registered

Good question. Why I ask the builder for further documentation. And back to the internet we go...

I believe your assumption of low efficiency is probably correct. Certainly at low speeds it seems to be the case. I never inspected these pumps, that was done by the drive shop in Sarasota that swapped the gearset for me and fixed all the leaks. Only have that spare unit pictured I pulled from a box of parts. Nothing replaceable besides the rollers. But these have to suck oil out of the reservoir 3" below the main case to operate in a "Dry Sump" environment.

Speaking with Tyson last night on a transmissions issue, was a simple stuck solenoid valve, and those are now working perfectly in all gears. I brought up these strange pumps. He's not played with em before either, but said the lower gear should sling enough oil up top if I raise the level. Those removing the dry sump feature.

Kinda reminds me of reading about the first guys to dry sump the #6 drives. How much oil is enough to make em live happy but not drag off a bunch of power. Reason I think we'll experiment once the cooling system is installed and I can spin things a bit faster while still on the trailer.

I believe your assumption of low efficiency is probably correct. Certainly at low speeds it seems to be the case. I never inspected these pumps, that was done by the drive shop in Sarasota that swapped the gearset for me and fixed all the leaks. Only have that spare unit pictured I pulled from a box of parts. Nothing replaceable besides the rollers. But these have to suck oil out of the reservoir 3" below the main case to operate in a "Dry Sump" environment.

Speaking with Tyson last night on a transmissions issue, was a simple stuck solenoid valve, and those are now working perfectly in all gears. I brought up these strange pumps. He's not played with em before either, but said the lower gear should sling enough oil up top if I raise the level. Those removing the dry sump feature.

Kinda reminds me of reading about the first guys to dry sump the #6 drives. How much oil is enough to make em live happy but not drag off a bunch of power. Reason I think we'll experiment once the cooling system is installed and I can spin things a bit faster while still on the trailer.

#408

Registered

Thread Starter

Thanks for the info. I plan to use those same pan temp senors.

Like typical vane pumps, guessing it takes some centrifugal force to expand these rollers. With no real specs on them, my only question is how well they flow around 2000rpm. The whole concept behind these drives was big torque diesels, which typically operate in the sub 3k rpm range.

Like typical vane pumps, guessing it takes some centrifugal force to expand these rollers. With no real specs on them, my only question is how well they flow around 2000rpm. The whole concept behind these drives was big torque diesels, which typically operate in the sub 3k rpm range.

#409

Registered

Thread Starter

Found a sticking low gear solenoid valve in the port transmission that was prohibiting it from shifting into the 1.5:1 ratio. Ruled out ellectrical, then t pull valve and tried cleaning it, soaking it in oil, moving the spring slider with a drill bit. But it refuses to free up where I would trust it. Being the last time these trannies spun props was three years at LOTO in Ron's 200mph club Skater, I'm gonna right this one off to shelf fatigue..

So I hit up Tyson to see if he has a spare laying around, which he doesn't. A little part number searching found a replacement in Cali, should be here tomorrow. What's funny, he tells me someone is sending a set of those trannies back for rebuild out of a Nor-Tech turbine Vee over in Thailand. Which makes me ask, is that the same boat these drives came from?

Swapped a valve from the STBD trans and it shifts into low gear perfect now. Also learned these transmissions can shift directly from neutral to low-forward or reverse without releasing the solenoids. Reverse gear is a 3:1 reduction at all times, and the 1.5:1 low-forward should make docking a bit easier.

Video below shows N to R and back on the Stbd transmission. With no resistance, driveshaft free spins easily. Both sides are checked out, time to bolt on some pipes and turbos.

HOORAY BEER !!

So I hit up Tyson to see if he has a spare laying around, which he doesn't. A little part number searching found a replacement in Cali, should be here tomorrow. What's funny, he tells me someone is sending a set of those trannies back for rebuild out of a Nor-Tech turbine Vee over in Thailand. Which makes me ask, is that the same boat these drives came from?

Swapped a valve from the STBD trans and it shifts into low gear perfect now. Also learned these transmissions can shift directly from neutral to low-forward or reverse without releasing the solenoids. Reverse gear is a 3:1 reduction at all times, and the 1.5:1 low-forward should make docking a bit easier.

Video below shows N to R and back on the Stbd transmission. With no resistance, driveshaft free spins easily. Both sides are checked out, time to bolt on some pipes and turbos.

HOORAY BEER !!

#410

Gold Member

Sorry if this is a derail but.....

There can't be many Nor-techs in Thailand, is it possible the boat had supercharged engines by TURBINE marine? This is an old add I remember seeing a couple of years ago. Probably doesn't make any difference anyway, but may help fill in some blanks.

http://www.leemarine.com/boats/listi...Nor-Tech-4300V

Lovin' your work KT, she's gonna be sensational down in Australia!

RR

There can't be many Nor-techs in Thailand, is it possible the boat had supercharged engines by TURBINE marine? This is an old add I remember seeing a couple of years ago. Probably doesn't make any difference anyway, but may help fill in some blanks.

http://www.leemarine.com/boats/listi...Nor-Tech-4300V

Lovin' your work KT, she's gonna be sensational down in Australia!

RR

Last edited by rak rua; 09-03-2019 at 09:13 PM.