Fountain 47, 2372cid single engine diesel

#104

Registered

Thread Starter

Poor man's coating to injector line special fittings. Phosphating process in the easiest way. After acid they bath in alkaline detergent to neutralize and then one hour in motor oil so they suck oil in coating cellular. Time will tell if they not get rust.

#105

Registered

Thread Starter

Scania 4 series thermostat housings have full internal flow when thermostats are closed, I think it's most important thing in marine engine cooling, no hot spots. Bottom flaps close bybass flow when thermostat opens and force all coolant to heat exchanger. Dual thermostat have few degree difference in opening temperature. Transmash will get own housing to each bank so right and left banks run in same stable temperature. Bigger ports are 60mm diameter so they have quite good flow.

The following users liked this post:

kidturbo (04-28-2021)

#106

Registered

Thread Starter

I found old video where we start Transmash alive. It's very rpm sensitive engine unlike conventional big diesels. It run good without flywheel, I won't add any weight to it except transmission internal inertia.

The following users liked this post:

sailtexas186548 (04-03-2021)

The following users liked this post:

ksalmine (04-04-2021)

#108

Registered

Thread Starter

Hope you see it next year....

#109

Registered

Thread Starter

Cooling system update. Threaded freeze plugs give great opportunity change coolant flow from longitudinal to transverse.

Flow route goes:

- pump

-exhaust manifolds

-heads

-cylinder blocks

-thermostat housing

-heat exchanger

-pump again

so flow is opposite as normal, coolest fluid see hottest place first. Exhaust ports and injector area get much better cooling and cylinder liners doesn't run too cold. Too cold liners cause seizing. Cummins guys should think same kind of cooling system on higher HP levels.....

Original freeze plugs get machined holes and o ringed connectors fit heads and manifolds together. I have to make special tool so fittings can screw in place.

You can see very dirty exaust ports, these engines have moderate oil consumption that must solve somehow. Better oil drain from heads and vacuum pump is first steps, if they don't help enough, better oil rings are in shopping cart. Controlled exhaust back pressure in idle may help also, but it kill idle sound....

The following 4 users liked this post by ksalmine:

#110

Registered

Thread Starter

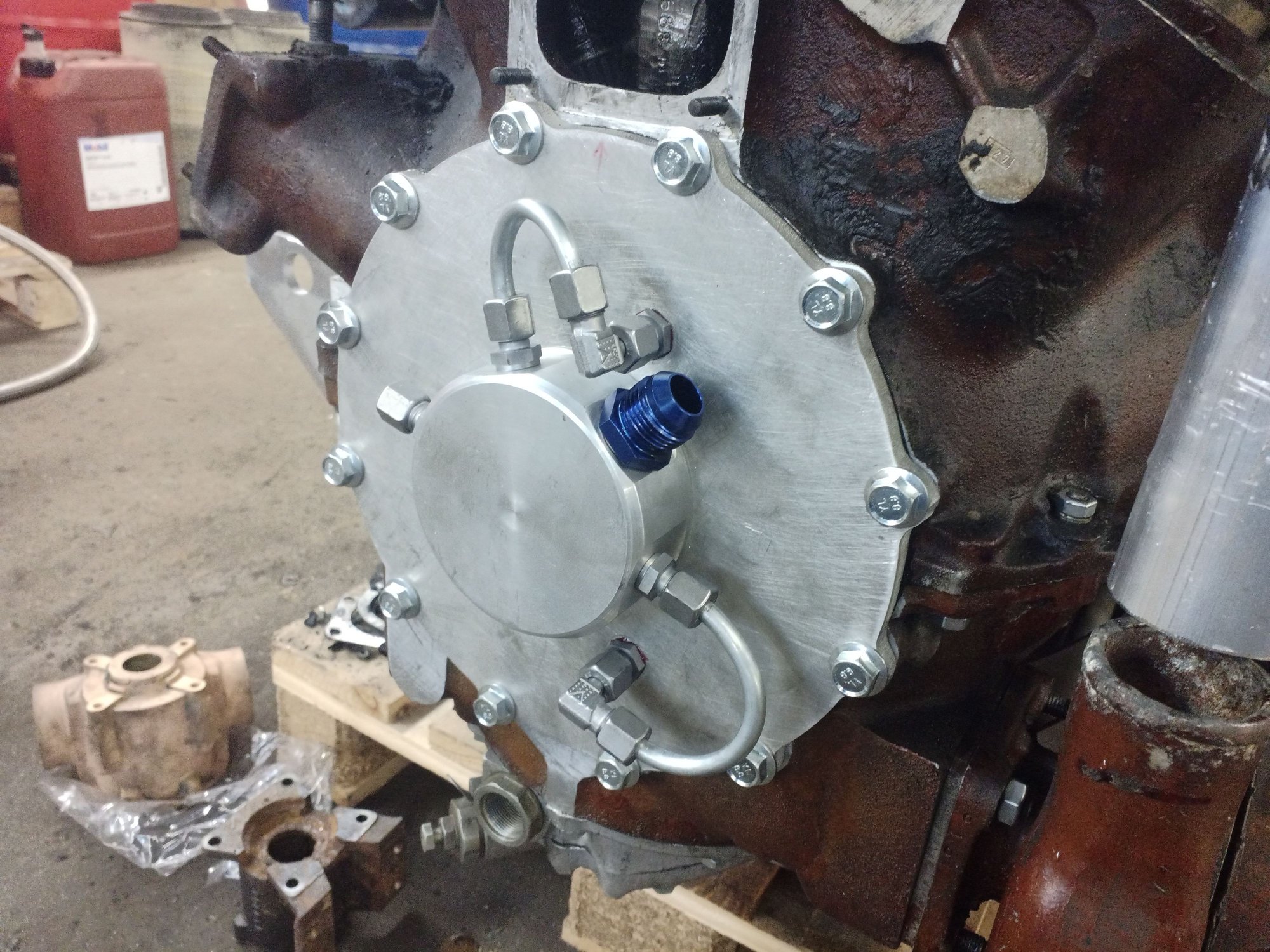

Monthly update, engine build go on slowly as usual.

crankshaft oil suply is ready and in place.

Fuel lift pumps and filters are test fitted to engine. Four Bosch 044 copy pumps flow 1000 liter/hour at 2 bar, probably I don't need that much flow but its easier use four. Two 12V pumps can connect in series so I can drive pumps at 24 volts. two pumps run normally, if flow is too small, I can start another pump package.

Water separator, raw filter and main fuel filters and bracket are from Volvo D13 engine.

Exhaust manifolds and water fittings are in place and now I'm working on cooling piping and thermostat housing.

Carbon fiber drive shafts are at the design stage, when prototype is ready stress tests must be performed. This engine eat conventional drive shafts at breakfast...

Stay tuned!

The following 8 users liked this post by ksalmine:

Gimme Fuel (05-28-2021), kidturbo (05-27-2021), outonsafari (05-26-2021), payuppsucker (05-26-2021), sailtexas186548 (05-26-2021), skunkie_racing (05-26-2021), SpidRacer (05-26-2021), underpsi68 (05-26-2021)