Fountain 47, 2372cid single engine diesel

#161

Registered

Thread Starter

Looks clever system! Quite difficult to get lower engines low enough to fit dropbox lower shaft. Long drive shafts helps if little angle is acceptable.

#162

Registered

Join Date: Jul 2021

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Hello, just wondering if you could help. We have a v12 transmash engine that is fitted to a pulling tractor. We are looking to identify the original firing order of the engine which we ‘believe’ we have identified, however we would like some confirmation about which cylinder the russians call their number 1 cylinder to commence the firing order. We have noted that in the building of the engine for fountain 47 you have fitted a p3000 bosch injector pump, did you have to re grind the cam in the pump to suit the firing order of the engine.

#163

Registered

I dont know how often ksalmine gets on here. I cant answer all your questions. But I do believe this picture from earlier in the thread will answer your #1 cylinder question.

#164

Registered

Thread Starter

Hello, just wondering if you could help. We have a v12 transmash engine that is fitted to a pulling tractor. We are looking to identify the original firing order of the engine which we ‘believe’ we have identified, however we would like some confirmation about which cylinder the russians call their number 1 cylinder to commence the firing order. We have noted that in the building of the engine for fountain 47 you have fitted a p3000 bosch injector pump, did you have to re grind the cam in the pump to suit the firing order of the engine.

Every other cam lobe is grind 10 pump degree later, then cam is heat treaded again and all lobes are precision grind to even fire. It succeeded perfectly because pump was in test bench and all plungers have same sized shim to adjust timing differences.

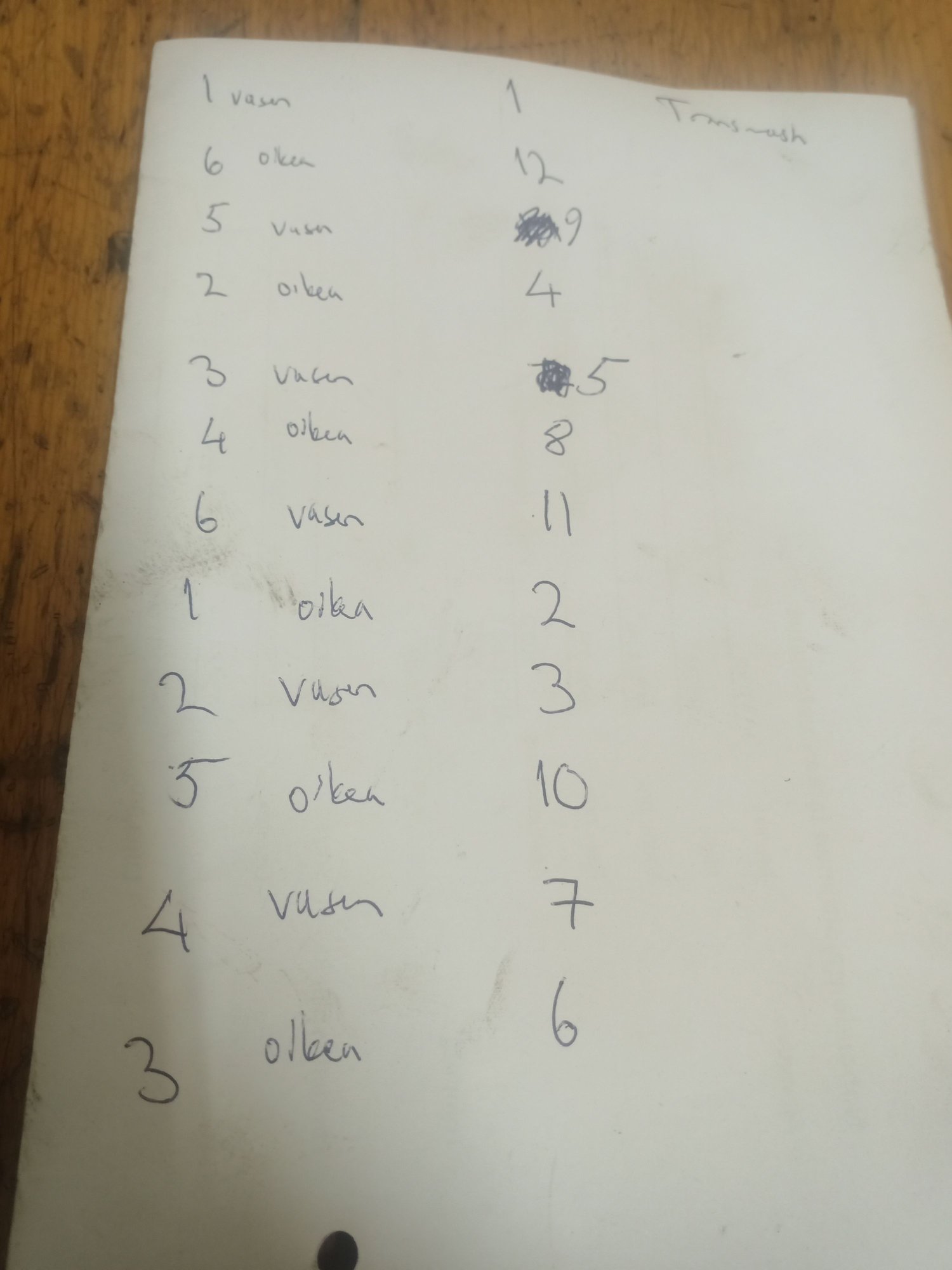

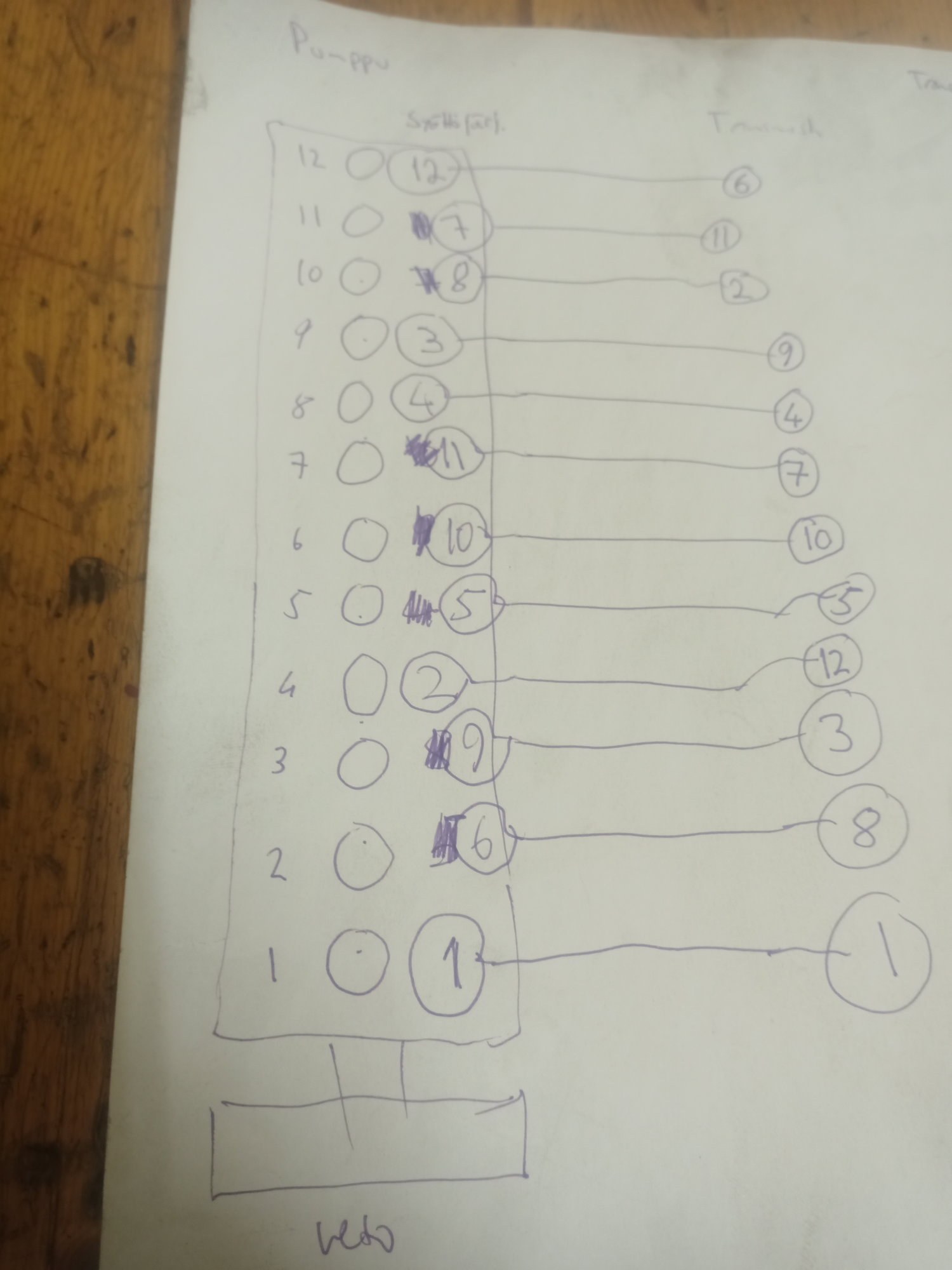

Here is few pictures solving firing order, they are poor hand drawings but hope you get help from it. Russians use left and right banks and cylinders are numbered 1-6. I name cylinders different, using pair and odd way.

Second picture show firing order. "vasen" is left in english and "oikea" is right. It's time to Finnish lesson!

I named left first cyl to no. 1 and right first to cyl no. 2.

The following users liked this post:

rak rua (02-22-2022)

#165

Registered

Thread Starter

I can't wait news from Kidturbo how spinning props in or out works, and thank you, this wake up some thinking in my head.

I have made my own mind work how props bite to water, but have to tell that I have absolutely zero know or experience on cleaver prop V hull. Just thinking...

OUT

IN

Pictures are quite good in scale to my 47', blue line is expected water height in props location based on one inch per foot raising ideology.

In first picture props turning out, V hull dig v shape hole to water so if prop bite only when there is enough water mass on blade, I think turning out have less working blade area than turning in. There are V shape hole between drives so props can throw water horizontal also and that reduce working blade area.

When turning in, V shape hole gives more water on blade and working area are better. This is my theory that can be very far from real world. I can't change rotation without building new split box, so this is quite important thing in Fountain project.

Carbon drive shaft mold is ready and in my friend shop that manufacture very nice light carbon fiber 23' outboard V hull boats. They laminate my drive shafts.

I have made my own mind work how props bite to water, but have to tell that I have absolutely zero know or experience on cleaver prop V hull. Just thinking...

OUT

IN

Pictures are quite good in scale to my 47', blue line is expected water height in props location based on one inch per foot raising ideology.

In first picture props turning out, V hull dig v shape hole to water so if prop bite only when there is enough water mass on blade, I think turning out have less working blade area than turning in. There are V shape hole between drives so props can throw water horizontal also and that reduce working blade area.

When turning in, V shape hole gives more water on blade and working area are better. This is my theory that can be very far from real world. I can't change rotation without building new split box, so this is quite important thing in Fountain project.

Carbon drive shaft mold is ready and in my friend shop that manufacture very nice light carbon fiber 23' outboard V hull boats. They laminate my drive shafts.

The following 4 users liked this post by ksalmine:

#167

Registered

I view the prop like a screw and anytime it can contact the water it will give you thrust . I believe the main benefit you get from the rotation has to do with the hull if you spin in it will pull the stern down and the bow up spinning out lifts the stern up and bow down , some hulls like bow lift some do not.

The following 2 users liked this post by green lightning:

hogie roll (04-19-2022), IGetWet (04-15-2022)

#168

Registered

Thread Starter

Yes prop act like screw but maybe if on blade is too small water mass when its near surface, it just throw water away and doesn’t make thrust at that prop area. they won’t make rooster if prop work like screw. Rooster water isn’t thrust but cool

Stern lift may reduce wetted surface but it can be dangerous if back of boat is out of water and boat run on first step and props. I think turn props in, it’s propably better if Transmash make huge power.

Stern lift may reduce wetted surface but it can be dangerous if back of boat is out of water and boat run on first step and props. I think turn props in, it’s propably better if Transmash make huge power.

The following users liked this post:

hogie roll (04-19-2022)

#169

Registered

Yes prop act like screw but maybe if on blade is too small water mass when its near surface, it just throw water away and doesn’t make thrust at that prop area. they won’t make rooster if prop work like screw. Rooster water isn’t thrust but cool

Stern lift may reduce wetted surface but it can be dangerous if back of boat is out of water and boat run on first step and props. I think turn props in, it’s propably better if Transmash make huge power.

Stern lift may reduce wetted surface but it can be dangerous if back of boat is out of water and boat run on first step and props. I think turn props in, it’s propably better if Transmash make huge power.