Fountain 47, 2372cid single engine diesel

#211

Registered

Music

The following users liked this post:

ksalmine (03-28-2023)

#213

Registered

I can agree on the chain reliability issue. At least I've heard of chain failures on ASD8 setups. However all those extra bearings on the idler gear design can create new issue too as I learned. More balls to fall out and get crunched between gears, vs a chain failure which may or may not take out the case and gears.

Most annoying part of the CNC case with all gear design was not having an inspection port to check said bearings and gears for excessive play or wear. On the W lower units, it was just black magic because ya have no way to inspect those or even monitor the oil temps.. Once they shot couple teeth out the case, well that's when ya knew ya have an issue. For the upper gear cases, I got smart and put a temp sensor in dry sump line so I knew if one was running hot. If cases were just filled, probably never experienced such failure issues.

Which brings me to my last point, on your case design,I feel it's gonna try to pump one side dry if not fully filled. Guessing you've already considered that. Simple crossover tube should keep both sides equal.

Most annoying part of the CNC case with all gear design was not having an inspection port to check said bearings and gears for excessive play or wear. On the W lower units, it was just black magic because ya have no way to inspect those or even monitor the oil temps.. Once they shot couple teeth out the case, well that's when ya knew ya have an issue. For the upper gear cases, I got smart and put a temp sensor in dry sump line so I knew if one was running hot. If cases were just filled, probably never experienced such failure issues.

Which brings me to my last point, on your case design,I feel it's gonna try to pump one side dry if not fully filled. Guessing you've already considered that. Simple crossover tube should keep both sides equal.

The following users liked this post:

AllDodge (03-29-2023)

#214

VIP Member

split box is awesome, looks great. Don't worry about 1 piece billet housing and the hardest gear sets.

I doubt it since you pay good attention to the small details, but maybe there will be a design change during construction/assembly or sea trials.

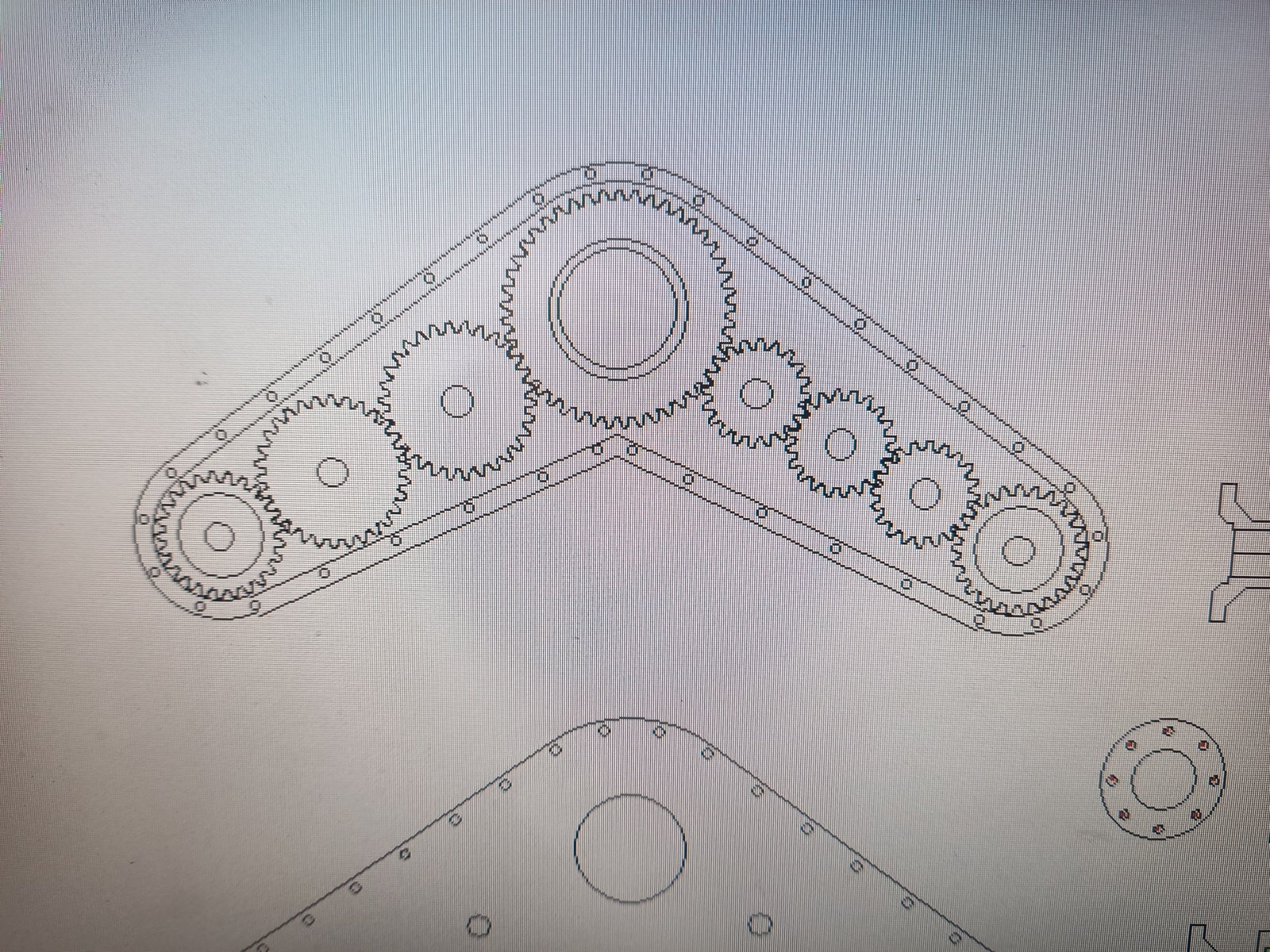

2 questions i have about the split box, i'm sure gear diameter/ tooth count gives you the same final ratio on both left and right,

1. would there be a torque or load difference between the 2 sides since there is more and smaller gears on 1 side?

2. Output for driveshafts are on 1 side of split box or both ? I ask because you will have to pick the props rotation to spin in our out.

my vote is to spin out.

your making great progress keep moving forward.

That seems like a lot of gear mesh parasitic loss. Why not increase gear sizes and eliminate the number of gears. Just looking at it, it seems like you could eliminate a gear on both sides and significantly reduce the parasitic loss as well as failure points. FWIW... I'd go bigger with your idler gears, rather than smaller than your drive and driven gears, to reduce their rotational speed. At the end of the day, the only thing that matters is the ratio between the drive and driven gears, anyway.

Thanks. Brad.

(937)545-8991

#215

Registered

Thread Starter

Kidturbo, what type bearings million dollar weisman transmissions use? Tapered roller bearings can take much more loads than ball bearings, I'm not concerned of bearing wear at all.

I think fill box with oil to about 1/3 of input gear, then it can't pump other side dry. Oil will be aerated so it won't make as much drag as fully filled stern drive.

Box could be done less gears but I don't think it can reduse loss much. teeth speed (m/s or ft/s) is same, only gear rpm change if intermediate gear are bigger or smaller. 4 tapered roller bearings doesn't make huge difference to total loss. Current box smaller intermediate gears are 20T and input gear is 45T, engine max rpm is 2500, intermediate gear run then 5625rpm, its not the problem. Smaller gears make less bearing load, bigger gear have more "lever arm" to make bigger load to bearings. Bigger intermediate gears make box bigger and heavier, gears itself also weight much more. Time will tell how this all ends.

Does anybody here know how much loss difference are between equal size bevel gear vs spur gear. I think spur gear are way more efficient. SSM 6-8 have 6 bevel gears and two spur gears inside that run very high speed in upper gearcase. My input gear rotates 2500rpm vs 6500rpm gas engine sterndrive. Propshaft speeds are the same so not much different there. I will put temp gauge to splitbox and test first without any water cooling, that will show how much power is converted to heat.

But all in all, I rather lose some propshaft power than take more weight to boat, power generation is not a problem, weight is.

I think fill box with oil to about 1/3 of input gear, then it can't pump other side dry. Oil will be aerated so it won't make as much drag as fully filled stern drive.

Box could be done less gears but I don't think it can reduse loss much. teeth speed (m/s or ft/s) is same, only gear rpm change if intermediate gear are bigger or smaller. 4 tapered roller bearings doesn't make huge difference to total loss. Current box smaller intermediate gears are 20T and input gear is 45T, engine max rpm is 2500, intermediate gear run then 5625rpm, its not the problem. Smaller gears make less bearing load, bigger gear have more "lever arm" to make bigger load to bearings. Bigger intermediate gears make box bigger and heavier, gears itself also weight much more. Time will tell how this all ends.

Does anybody here know how much loss difference are between equal size bevel gear vs spur gear. I think spur gear are way more efficient. SSM 6-8 have 6 bevel gears and two spur gears inside that run very high speed in upper gearcase. My input gear rotates 2500rpm vs 6500rpm gas engine sterndrive. Propshaft speeds are the same so not much different there. I will put temp gauge to splitbox and test first without any water cooling, that will show how much power is converted to heat.

But all in all, I rather lose some propshaft power than take more weight to boat, power generation is not a problem, weight is.

#216

Registered

I might use the word "balls" a bit generously relating to bearings. Actually the W's had good tapered bearings, and use double stacked gears, which seamed to transfer 1000+lbft quite well. However without any access to inspect the guts beyond splitting the case, and after setting dry for a couple years, a cage failed [top photo] on our first outing. Just heard bang as bearing went thru the teeth [bottom photo].

#217

Registered

Thread Starter

That look sad. Bearing cage had dark brown color, could it be sign of overheating? Lack of lubrication means lack of cooling too. W parts look good designed but always can be some failures that can not be imagined on engineering table. Everybody could make this if its easy but it isn't. Factorys use millions for R&D. I try do same in my one man heavy vehicle drivetrain and engine shop without millions.

I don't think you W's blow up for weakness, there could be another reason for example heat and lubrication. In dry sump systems some component can run less lubrication than another if there is engineering bug. Almoust full filled box will get lubrication everywhere, penalty is power loss but that is way better than broken parts. I have seen 1.5million kilometers driven transmission that look like new and they have splash lubrication to gears and pump for bearings, that could be good route to my configuration.

I don't think you W's blow up for weakness, there could be another reason for example heat and lubrication. In dry sump systems some component can run less lubrication than another if there is engineering bug. Almoust full filled box will get lubrication everywhere, penalty is power loss but that is way better than broken parts. I have seen 1.5million kilometers driven transmission that look like new and they have splash lubrication to gears and pump for bearings, that could be good route to my configuration.

The following users liked this post:

kidturbo (04-05-2023)

The following users liked this post:

ksalmine (05-17-2023)

#219

Registered

Thread Starter

Project going on slowly as usually. Splitbox is weld and going to machine shop tomorrow. I mill, drill and make threads for oil drain and fill points to drives, drive assembly tools are ready. Ball and bearing housings have tool holes now for tightening all together right.

Extension box drawings are ready and they has been ordered from local metal work company. laser cut parts, high accuracy. Should be ready in few months.

Carbon fiber driveshafts is not ready yet, yesterday I ask composite company keep hurry. Our new house and garage are almost ready, should get permit to move from city building control in few weeks, after that Fountain project should start making bigger steps to forward. Boat fit inside my new garage so I have to haul it in before autumn.

If I get all individual parts ready before late autumn, boat should see water in next summer, maybe.

I found cracked Transmash cylinder head for flow research and development, intake ports have so bad flow that they have to modify. Not now but in future, aluminium bronze valve guides and seats are also on list. I bought Performance Trends Engine analyzer pro software to find out right way to engine modification. After I get real flow numbers, software should be pretty accurate, near future you will see simulated dyno pulls...

By the way, 150mm bore is quite big as you can see in cylinder head picture intake valves are 2.12" and ex 1.97"

intake valves are 2.12" and ex 1.97"

Extension box drawings are ready and they has been ordered from local metal work company. laser cut parts, high accuracy. Should be ready in few months.

Carbon fiber driveshafts is not ready yet, yesterday I ask composite company keep hurry. Our new house and garage are almost ready, should get permit to move from city building control in few weeks, after that Fountain project should start making bigger steps to forward. Boat fit inside my new garage so I have to haul it in before autumn.

If I get all individual parts ready before late autumn, boat should see water in next summer, maybe.

I found cracked Transmash cylinder head for flow research and development, intake ports have so bad flow that they have to modify. Not now but in future, aluminium bronze valve guides and seats are also on list. I bought Performance Trends Engine analyzer pro software to find out right way to engine modification. After I get real flow numbers, software should be pretty accurate, near future you will see simulated dyno pulls...

By the way, 150mm bore is quite big as you can see in cylinder head picture

intake valves are 2.12" and ex 1.97"

intake valves are 2.12" and ex 1.97"

The following 2 users liked this post by ksalmine:

Samer (09-17-2023), Twin O/B Sonic (06-02-2023)