Fountain 47, 2372cid single engine diesel

#261

Registered

Nice work on the extension boxes..

Did you have as much fun building those out of stainless as I did from aluminum? Was a task with 1" thick plates, machining the angles correct on top an bottom. Looks easier out of stainless, from way over here at least..

Did you have as much fun building those out of stainless as I did from aluminum? Was a task with 1" thick plates, machining the angles correct on top an bottom. Looks easier out of stainless, from way over here at least..

#262

Registered

Thread Starter

Kidturbo, all do it yourself boat building is fun, part of hobby. Actually I just draw 2D CAD drawings and buy boxes from next town metal workshop, they were so cheap that no sense to cut and drill them myself. Boxes are made S355 steel, no stainless, they will go to sandblast and get epoxy coat on. All other parts are 304 stainless.

Thinking and calculating angles and dimensions are fun, I think you like it also.

I thought first to made aluminium boxes but weight would be almost same, steel boxes can be about half thinner material and threads are more durable. Welding is much easier to steel boxes.

Hydraulic hose pass trough connectors are also easy because I can weld double ended fitting to extension box, separated inner and outer hoses.

Thinking and calculating angles and dimensions are fun, I think you like it also.

I thought first to made aluminium boxes but weight would be almost same, steel boxes can be about half thinner material and threads are more durable. Welding is much easier to steel boxes.

Hydraulic hose pass trough connectors are also easy because I can weld double ended fitting to extension box, separated inner and outer hoses.

The following 2 users liked this post by ksalmine:

kidturbo (11-30-2023), Twin O/B Sonic (11-29-2023)

#263

Platinum Member

All the work you are doing is incredible!

I truly enjoy seeing your updates.

If I might make a suggestion on coating the extension boxes, I love powder-coating, but plowing snow for decades has shown me that if it gets damaged and salt gets under, it can go unseen for a while causing chaos. If it were mine, I would consider galvanized coating, then painting. Unfortunately the paint is not going to stick very well to galvanizing. A better option to be able to paint is galvannealing. Over here galvanizing it is quite inexpensive, I have not had parts galvannealed (but I have purchased parts) so I don't know the cost. Just my thoughts.

I truly enjoy seeing your updates.

If I might make a suggestion on coating the extension boxes, I love powder-coating, but plowing snow for decades has shown me that if it gets damaged and salt gets under, it can go unseen for a while causing chaos. If it were mine, I would consider galvanized coating, then painting. Unfortunately the paint is not going to stick very well to galvanizing. A better option to be able to paint is galvannealing. Over here galvanizing it is quite inexpensive, I have not had parts galvannealed (but I have purchased parts) so I don't know the cost. Just my thoughts.

#264

Registered

Thread Starter

Thanks! I don't like powder coating at all. If water goes under coating it start loose bigger parts. I like epoxy coatings, they don't come of even there is scratch on it. Actually in Finland we have few local paint manufacturers and they have very good products. Ship manufacturing to harsh north enviroments may have forced to paint manufacturers deveploment best products. The largest cruise ship ever manufactured have been made 150km from me, https://en.wikipedia.org/wiki/Icon-class_cruise_ship

I don't like galvanizing either, paint stick better to bare steel than over zink plating. Ships and steel boats are all just paint and they survive well.

Building has made progress again, I will update soon....

I don't like galvanizing either, paint stick better to bare steel than over zink plating. Ships and steel boats are all just paint and they survive well.

Building has made progress again, I will update soon....

The following users liked this post:

resurrected (12-11-2023)

#267

Registered

Thread Starter

#268

Registered

Thread Starter

Things are going forward. Turbos are installed, charge pipes weld, support bracket is ready and exhaust pipes half ready.

I cut manifold-turbo connector tubes aparts again and lift chargers up 90mm, there was some measure error before, tail pipes could be under water. Its now fixed and I put AFR, EGT and exhaust pressure gauge fittings also, every possible data must analyze when this engine do serious work.

Turbo support tube is not prettiest one but there is not any bolts near chargers so this was only choice. I don't want all weight on cast aluminium exhaust manifolds.

Tomorrow come more pictures and detailed information....

I cut manifold-turbo connector tubes aparts again and lift chargers up 90mm, there was some measure error before, tail pipes could be under water. Its now fixed and I put AFR, EGT and exhaust pressure gauge fittings also, every possible data must analyze when this engine do serious work.

Turbo support tube is not prettiest one but there is not any bolts near chargers so this was only choice. I don't want all weight on cast aluminium exhaust manifolds.

Tomorrow come more pictures and detailed information....

The following 6 users liked this post by ksalmine:

AllDodge (12-16-2023), offshorexcursion (12-16-2023), scippy (12-16-2023), thegoodson (12-16-2023), Twin O/B Sonic (12-16-2023), underpsi68 (12-16-2023)

#269

Registered

Thread Starter

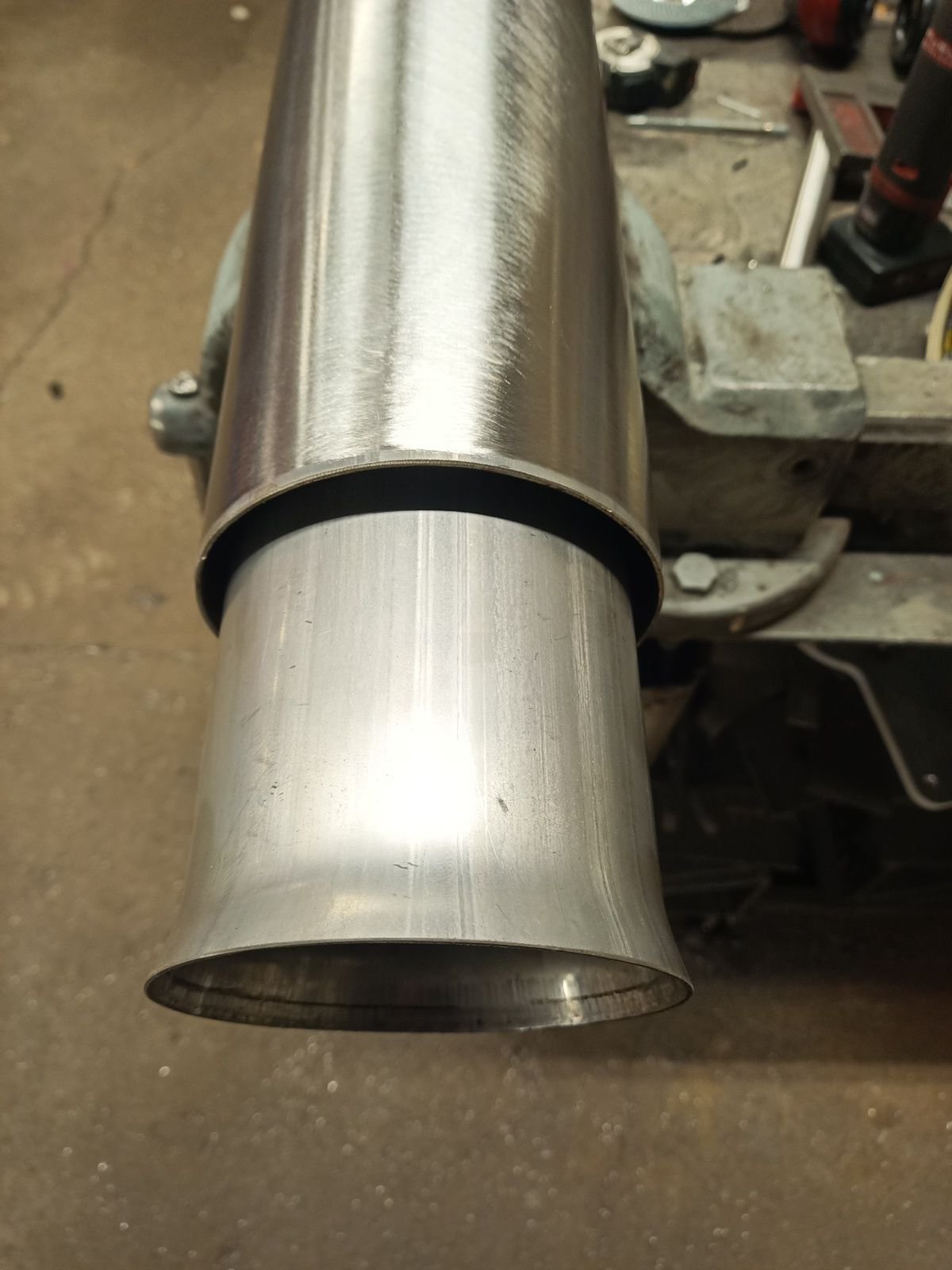

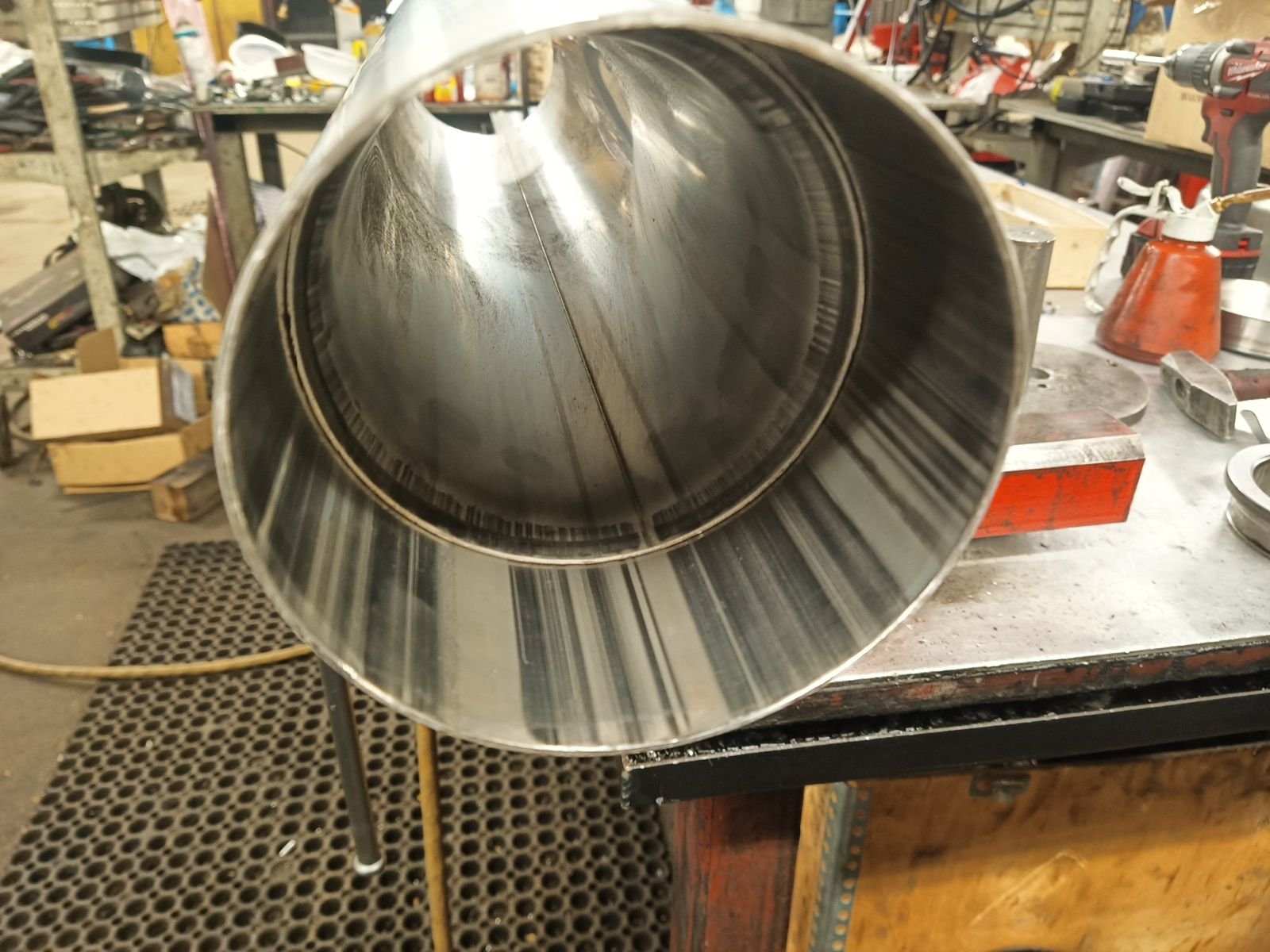

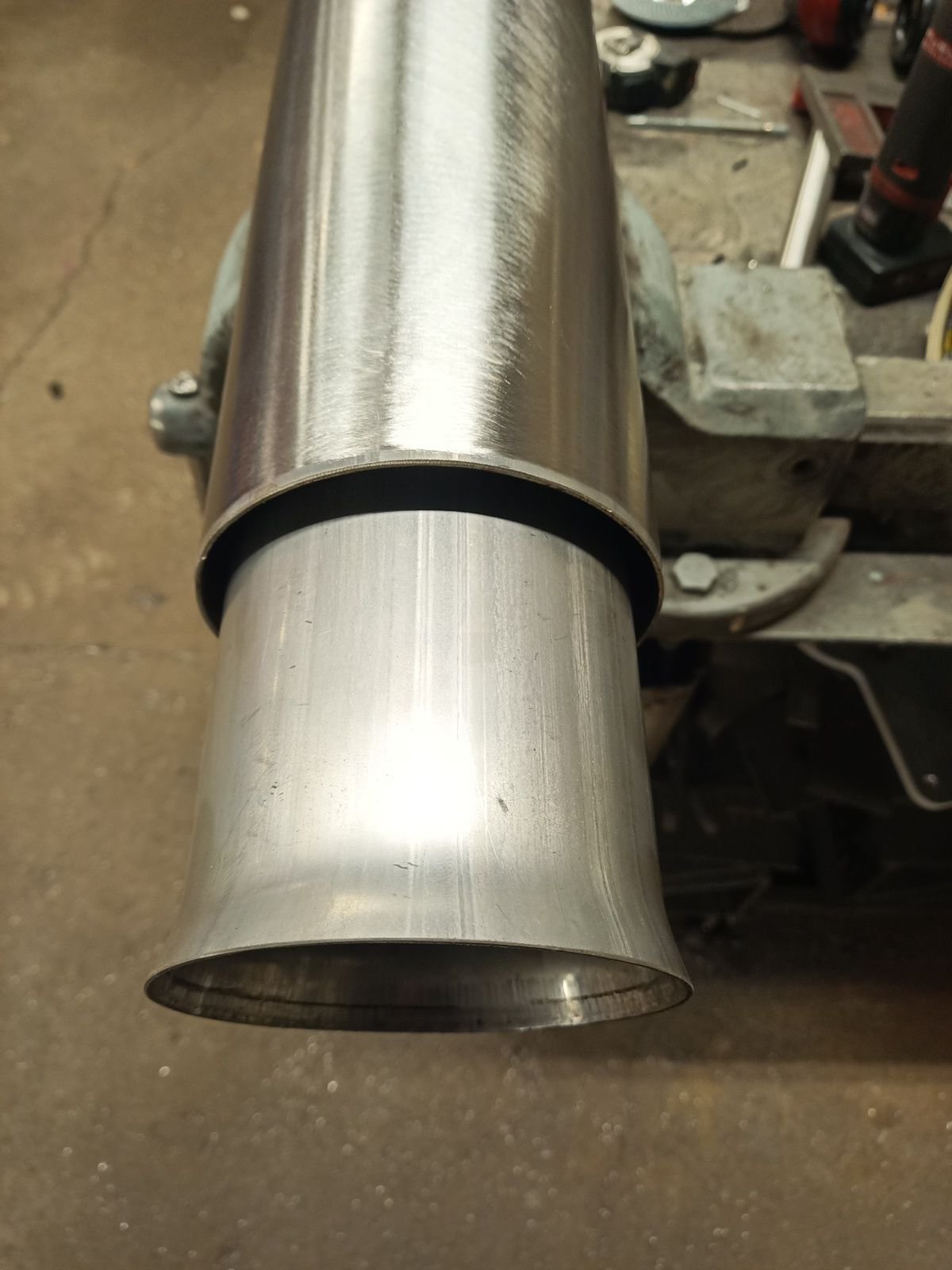

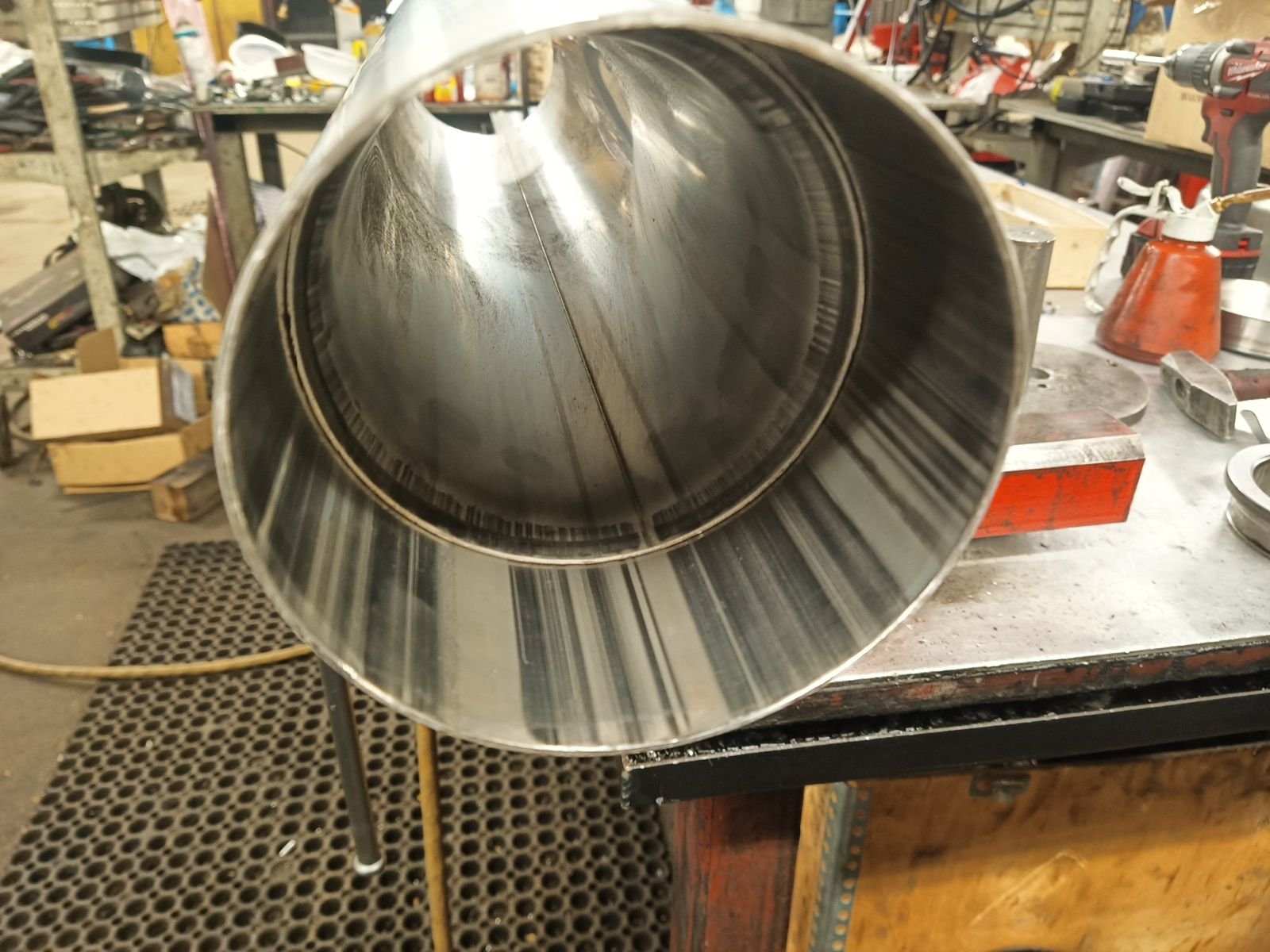

Tailpipes build is nice work to do. I try reduce 5" outer stainless tube and spread 4.5" inner tube, it was success.

There is perfect fit to weld between inner and outer tube.

It taker 1.5 ton force to press tubes together. Inner tube spread is 1mm bigger than outer tube inside diameter, so I will not weld output side at all. It can leak few drops water to exhaust stream but its ok, this engine won't have reversion. Benefit is that tailpipes will never crack because inner tube is weld just in the other end and another end can move a little by heat expansion.

Inner tubes are shorter at output end because there will be exhaust pressure control flaps. I try run engine at idle flaps so much closed that it makes 2 bar backpressure. When intake and exhaust valve is open in same time, hot exhaust air will flow to intake manifold and act like EGR system, it preheat intake air and help engine warm up and take out the haze that can appear when engine is cold.

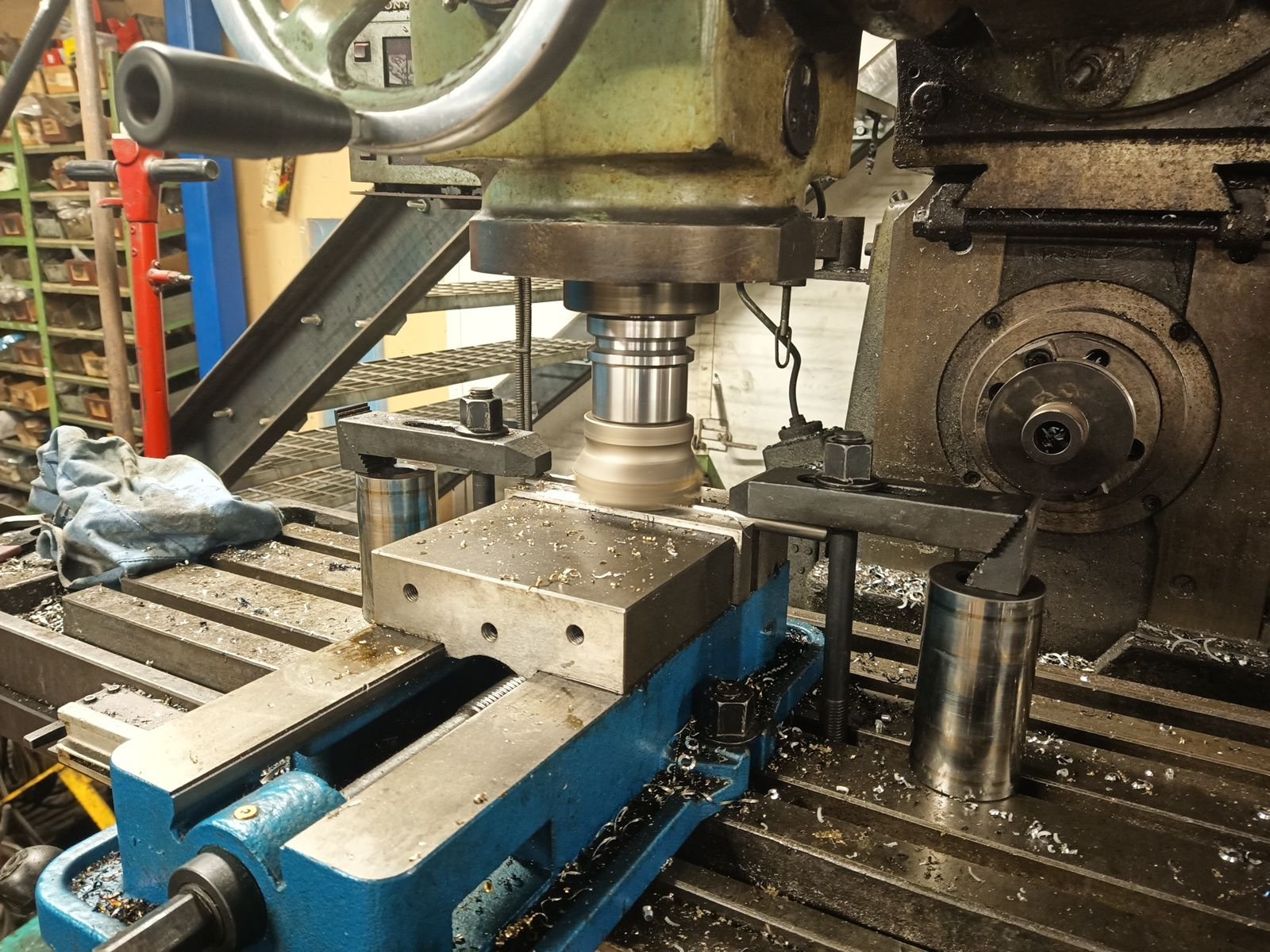

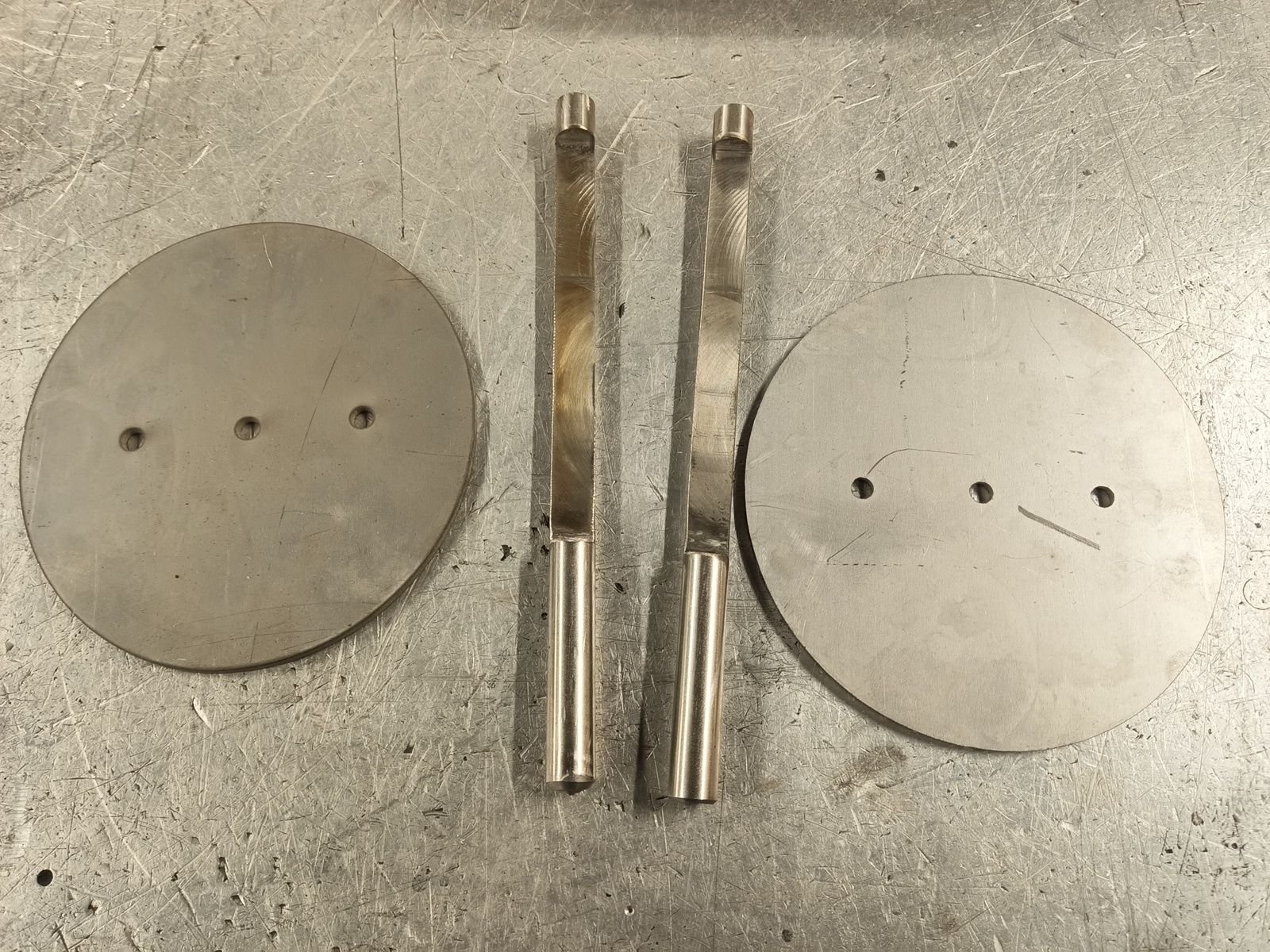

Flap shaft are made off 12mm 304 stainless shaft and milled flat at center. Flaps are 3mm water cut stainless oval shaped so they fit pretty good inside 5" tubes. Actuators are single acting spring loaded so when boat sit in water and engine is shut, flaps are closed when waves hit under swimplatform water can't go to turbos and exhaust manifolds. Exhaust pressure control flap position to keep 2 bars at idle, I will put solenoid valve to force them open when gear is engaged and if I wan't listen cruel V12 twin turbo sound

There is perfect fit to weld between inner and outer tube.

It taker 1.5 ton force to press tubes together. Inner tube spread is 1mm bigger than outer tube inside diameter, so I will not weld output side at all. It can leak few drops water to exhaust stream but its ok, this engine won't have reversion. Benefit is that tailpipes will never crack because inner tube is weld just in the other end and another end can move a little by heat expansion.

Inner tubes are shorter at output end because there will be exhaust pressure control flaps. I try run engine at idle flaps so much closed that it makes 2 bar backpressure. When intake and exhaust valve is open in same time, hot exhaust air will flow to intake manifold and act like EGR system, it preheat intake air and help engine warm up and take out the haze that can appear when engine is cold.

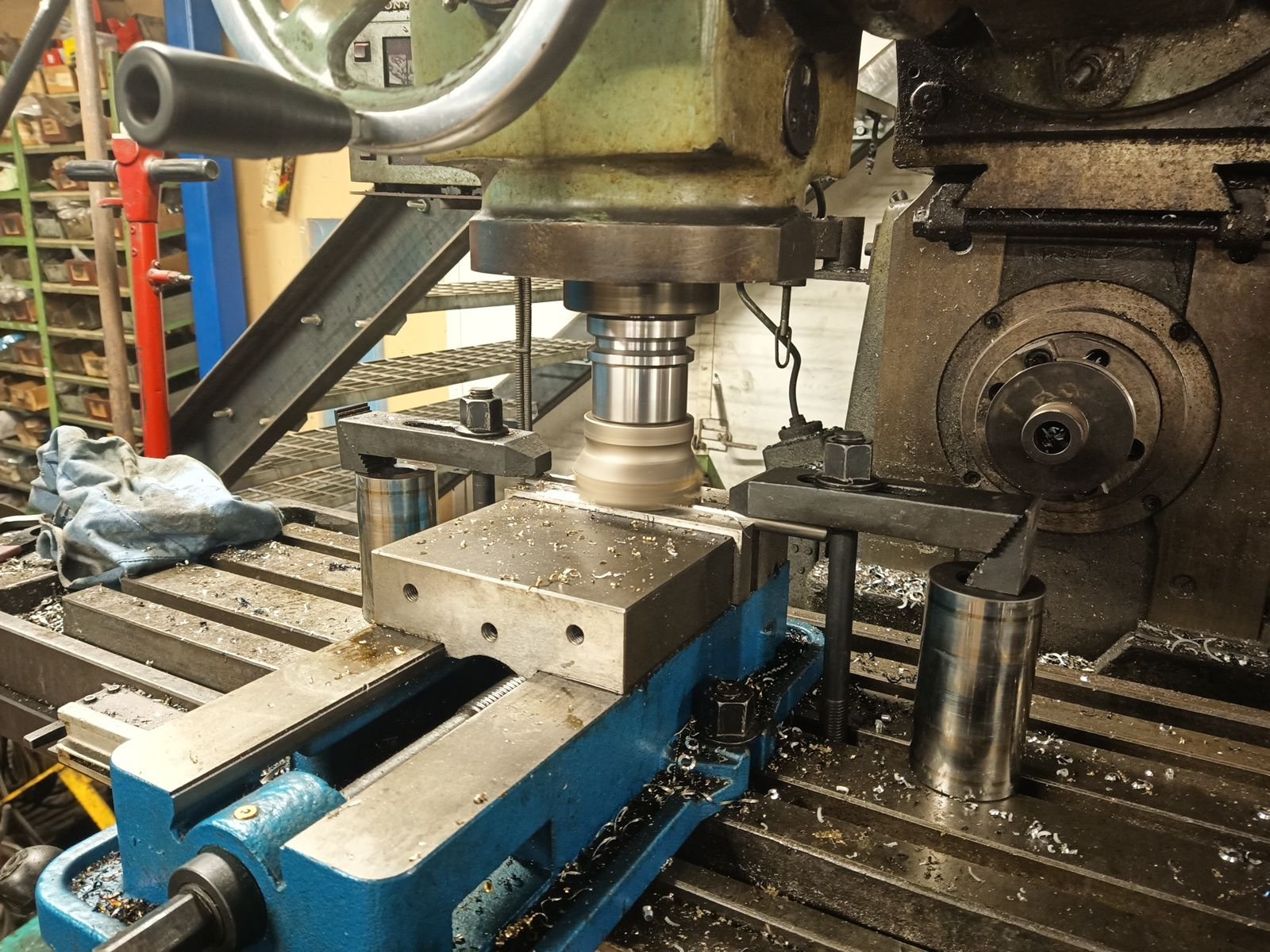

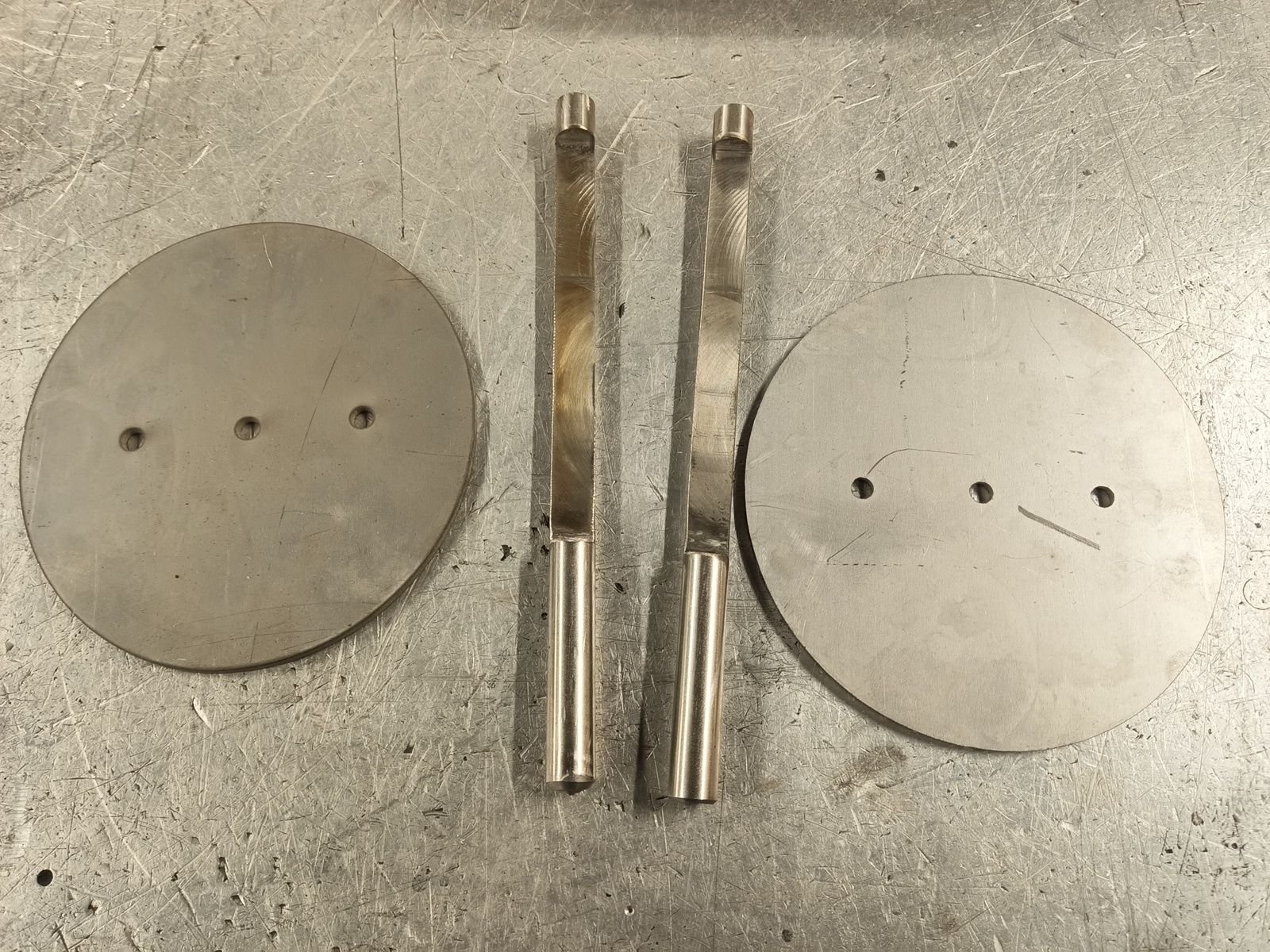

Flap shaft are made off 12mm 304 stainless shaft and milled flat at center. Flaps are 3mm water cut stainless oval shaped so they fit pretty good inside 5" tubes. Actuators are single acting spring loaded so when boat sit in water and engine is shut, flaps are closed when waves hit under swimplatform water can't go to turbos and exhaust manifolds. Exhaust pressure control flap position to keep 2 bars at idle, I will put solenoid valve to force them open when gear is engaged and if I wan't listen cruel V12 twin turbo sound

The following 4 users liked this post by ksalmine: