Fountain 47, 2372cid single engine diesel

#322

Registered

Can’t wait to see this thing running.

The following users liked this post:

ksalmine (04-21-2024)

#324

Registered

Thread Starter

Many different composite works is going in same time, Transom curved few millimeters, so I straighten it up using thickened vinylester and last fairing will be done by sanding thick epoxy primer absolute straight. Extension boxes are big so they need straight mounting surface. My friend mill boxes straight, he have bigger machine than mine and I have to get some help this big project. Vibration was bad problem but he figured it out.

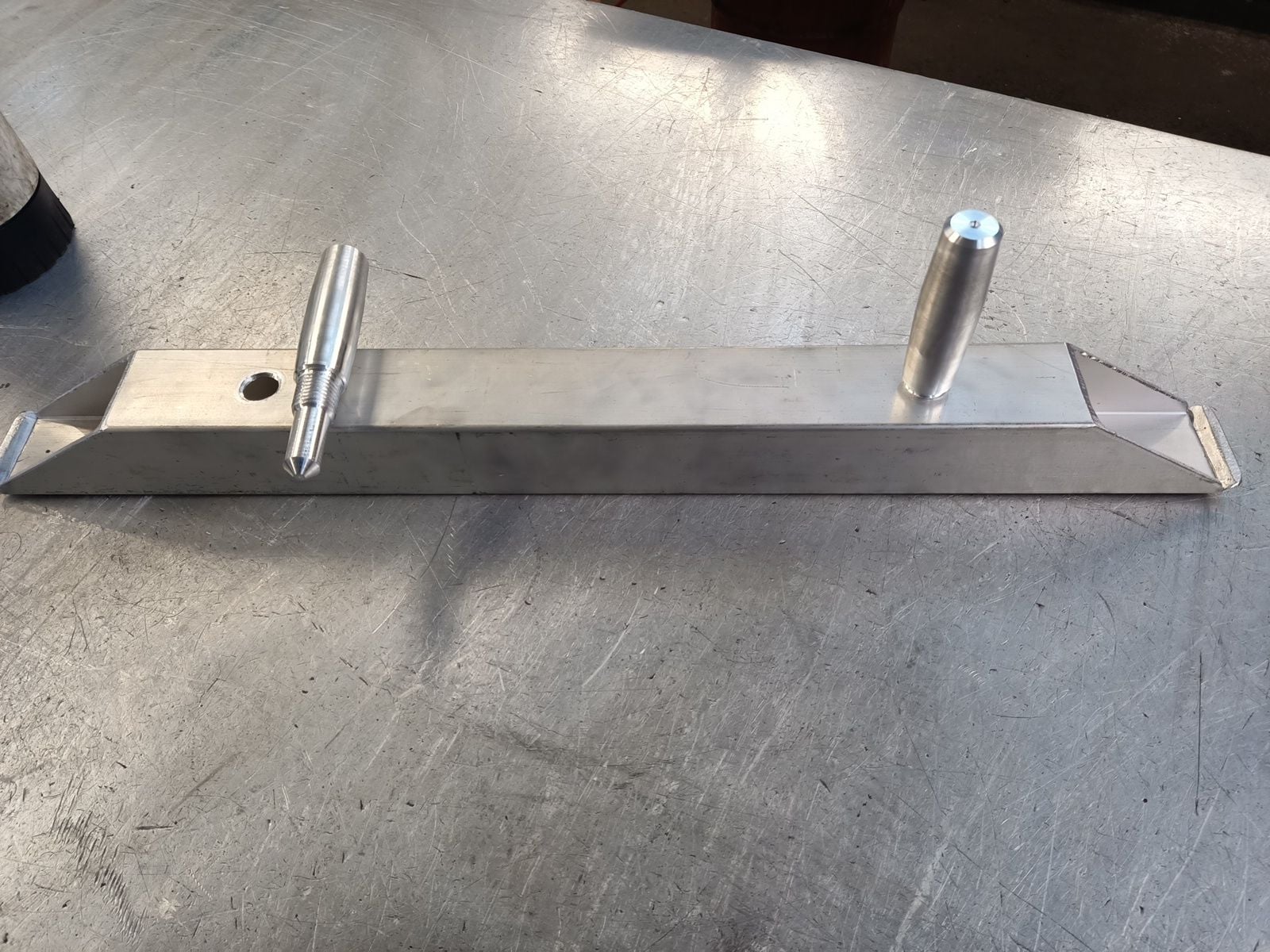

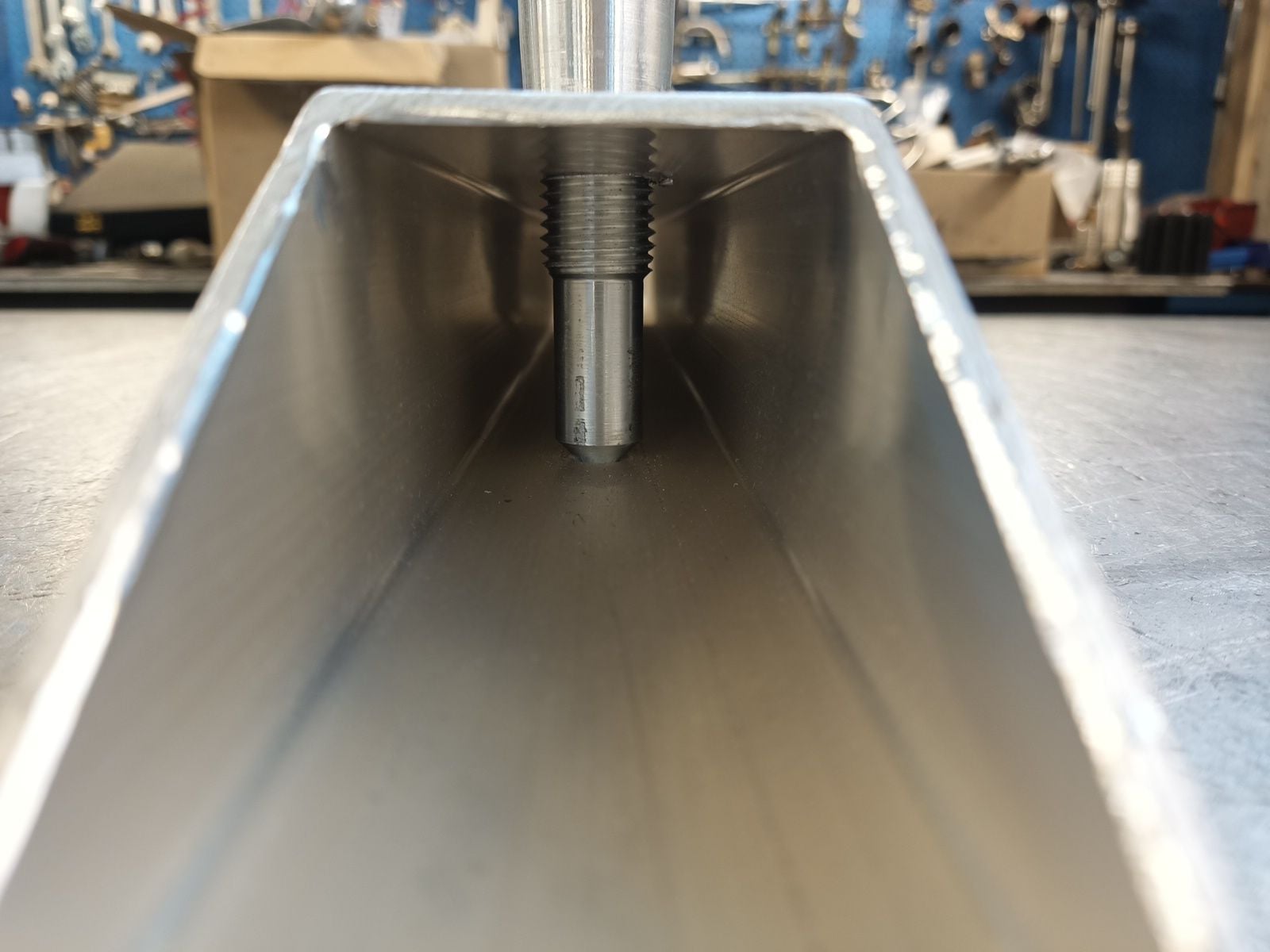

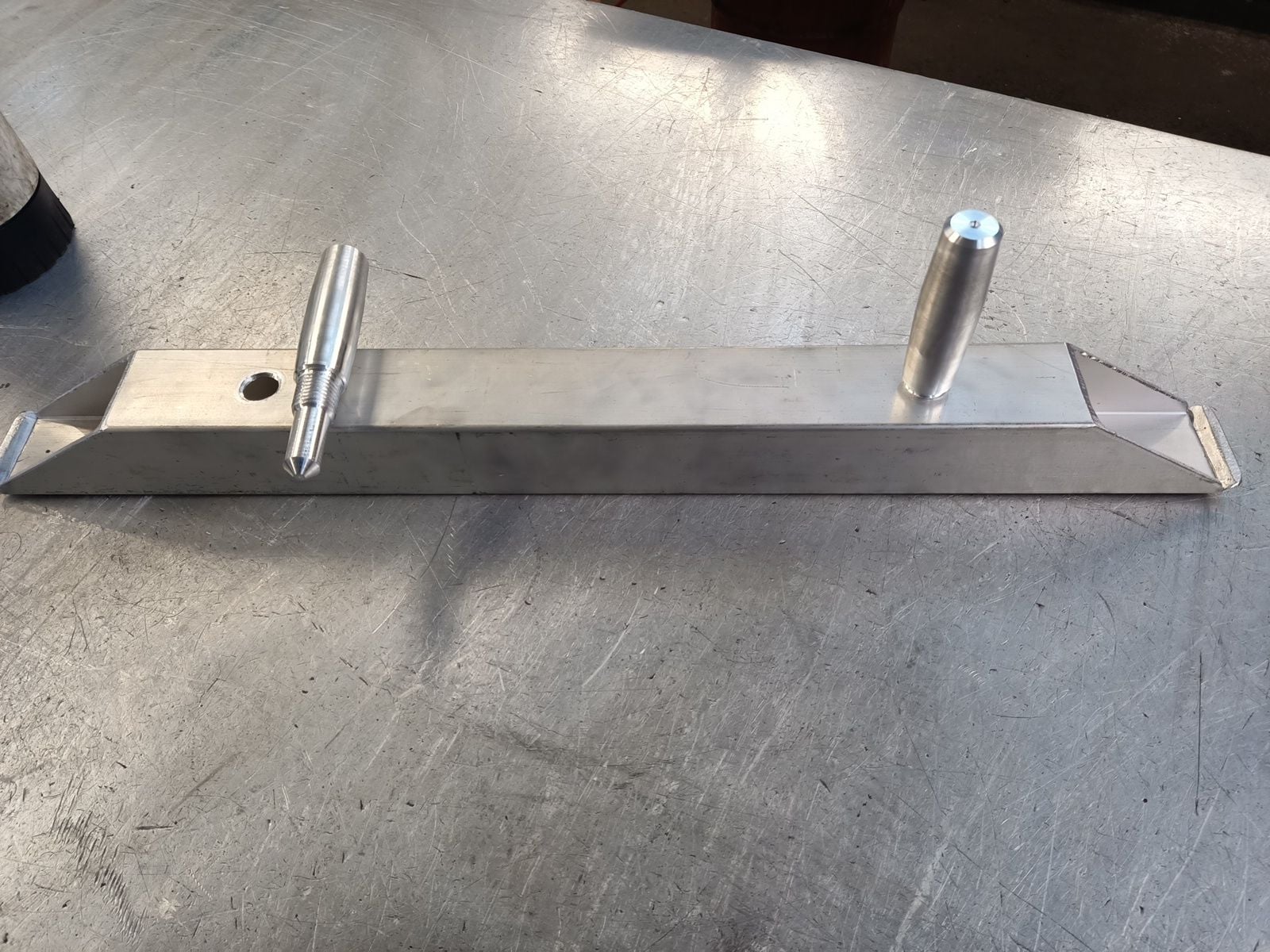

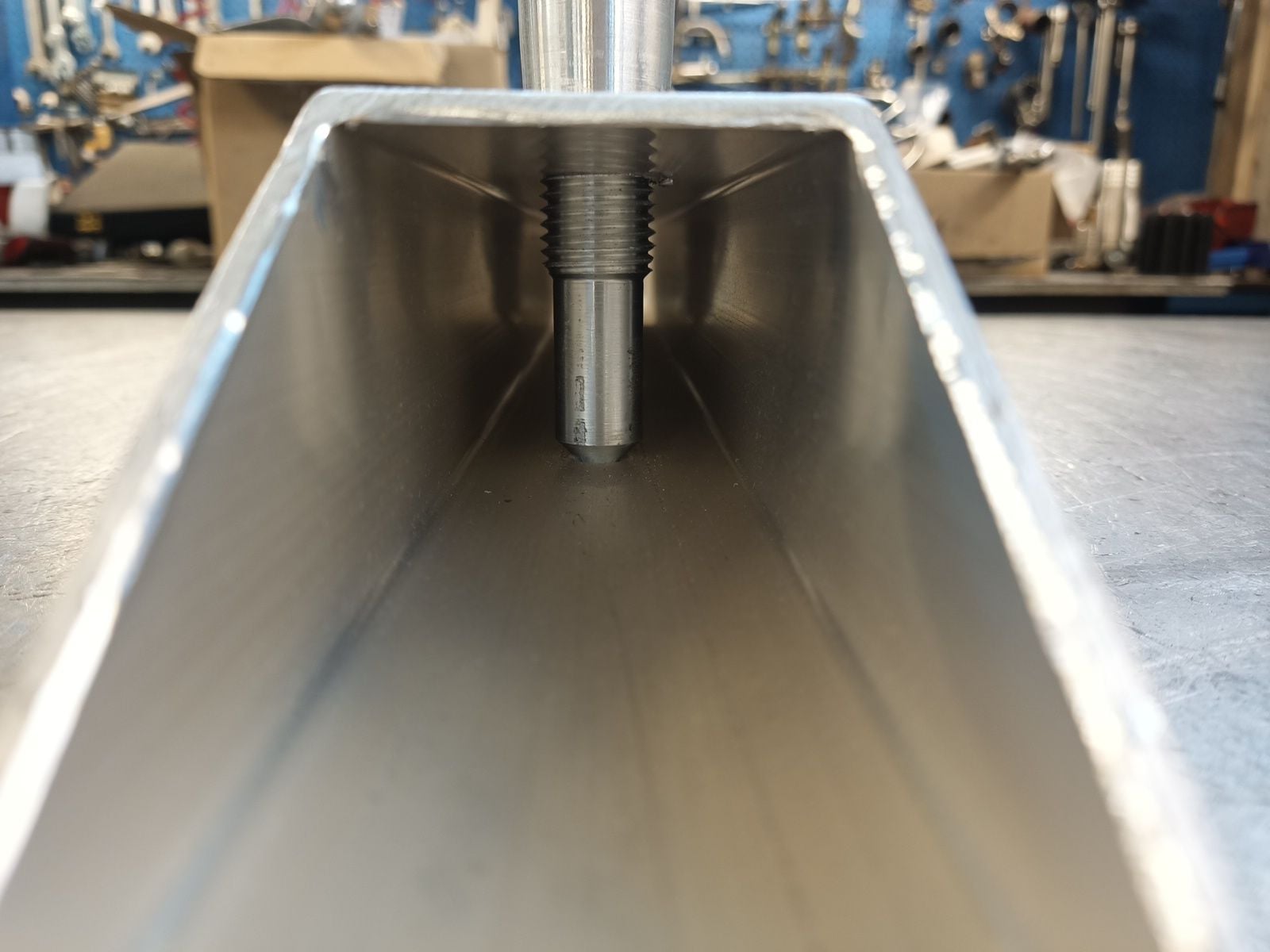

I have been searching good sanding plane but all are like children plastic carpenter toys. I made my own, 6082 aluminium, it will never broke

Longitudinal stringer cores are in place and sharp edges rounded. Its high density PET foam, under 1% water absorbion and easy to handle.

Middle stringers is almost middle off extension box hole, maybe they transfer some force from transom to boat bottom and make all more rigid.

Stringers fabrics is cut ready, tomorrow evening is lamination time and I hope to get all four stringers ready. It's pretty time consuming to do yourself.

I found nice high density urethane foam cheap, scale say that they are 105kg/m3, just right material to main stringers. PET foam is not good for carry engine weight because it have grain structure like wood and I can not put it in right direction these taller stringers. Urethane is similar in all directions so its better material to this. I need unidiagonal fiber to make some reinforcement, maube carbon fiber.

I have been searching good sanding plane but all are like children plastic carpenter toys. I made my own, 6082 aluminium, it will never broke

Longitudinal stringer cores are in place and sharp edges rounded. Its high density PET foam, under 1% water absorbion and easy to handle.

Middle stringers is almost middle off extension box hole, maybe they transfer some force from transom to boat bottom and make all more rigid.

Stringers fabrics is cut ready, tomorrow evening is lamination time and I hope to get all four stringers ready. It's pretty time consuming to do yourself.

I found nice high density urethane foam cheap, scale say that they are 105kg/m3, just right material to main stringers. PET foam is not good for carry engine weight because it have grain structure like wood and I can not put it in right direction these taller stringers. Urethane is similar in all directions so its better material to this. I need unidiagonal fiber to make some reinforcement, maube carbon fiber.

The following 5 users liked this post by ksalmine:

AllDodge (04-21-2024), IGetWet (04-22-2024), rak rua (04-21-2024), resurrected (05-03-2024), Twin O/B Sonic (04-21-2024)

#325

VIP Member

Ksalmine,

Is that Divinycell? We use the 4 or 6lb/ft3 for sponsons in our model boats. Your 105Kg/m3 is equivalent to about 6lb/ft3. Laminated with just 1/32” (.8mm) birch plywood, it is incredibly strong, and, as you say, virtually does not absorb water. Good stuff.

Thanks. Brad.

Is that Divinycell? We use the 4 or 6lb/ft3 for sponsons in our model boats. Your 105Kg/m3 is equivalent to about 6lb/ft3. Laminated with just 1/32” (.8mm) birch plywood, it is incredibly strong, and, as you say, virtually does not absorb water. Good stuff.

Thanks. Brad.

#326

Registered

Brad, PU is not divinylcell.

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

#327

VIP Member

Brad, PU is not divinylcell.

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

We use divinycell a lot in our “wood over foam” constructions, and I’ve always heard it described as a “urethane foam”, but, you’re right… Going to DiabGroup, I see that divinyell is actually a PVC. It would definitely work for what Ksalmine is doing, though, I’d think. I wouldn’t want to clamp through it with motor mount bolts and such without an end grain compression core, but it would otherwise be plenty strong enough, properly laminated with glass/CF. DVC wets out with epoxy extremely well. Not sure about PE resins , though. Never done that.

Thanks. Brad.

#328

Registered

Thread Starter

Brad, PU is not divinylcell.

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

Ksalminen, are you sure PU foam will work? Never heard of anyone using it.

https://www.boatdesign.net/threads/p...or-other.8900/

#329

Registered

Thread Starter

All small stringers are glassed, it can be feel how boat bottom stop vibrating when you kick it, before stringers it was pretty soft, but not anymore.

Urethane foam I had was only 100cmx100cm flats and stringer is 235cm long so I have to glass three pieces together with 10cm chop mat on both sides. This way stringer is straight and easy to glue in boat. Stringer core weight only 2kg, same size old ones weight about 20kg....

Single engine 47' boat stringer system is not ordinary, I think to make horzontal sandwitch panels between stringer and hull side to keep stringers more solid at horizontal direction. It helps working next to the engine when you have straight walking platform, all equipment is also easier to fasten.

Sharp radiuses are rounded, next thing is deside fabrics and cut them. I thin overbuild these stringers because engine will mount on top of them.

Urethane foam I had was only 100cmx100cm flats and stringer is 235cm long so I have to glass three pieces together with 10cm chop mat on both sides. This way stringer is straight and easy to glue in boat. Stringer core weight only 2kg, same size old ones weight about 20kg....

Single engine 47' boat stringer system is not ordinary, I think to make horzontal sandwitch panels between stringer and hull side to keep stringers more solid at horizontal direction. It helps working next to the engine when you have straight walking platform, all equipment is also easier to fasten.

Sharp radiuses are rounded, next thing is deside fabrics and cut them. I thin overbuild these stringers because engine will mount on top of them.

Last edited by ksalmine; 05-01-2024 at 10:17 PM.

The following users liked this post:

smashm (05-17-2024)

#330

Registered

Thread Starter

Long time, no post, but all is going forward slowly. Glass work is near complete, next job is get engine comparement paint and fairing and painting transom. I made walking platforms between main stringer and hull side, it help also stiffen stringer at horizontal way, engine-transmission-splitbox package is pretty heavy so stringers will get sideway load too. There will be no rubber mounts to engine, all will be bolted solid structure.

Extension boxes are ready and painted, waiting for assembly.

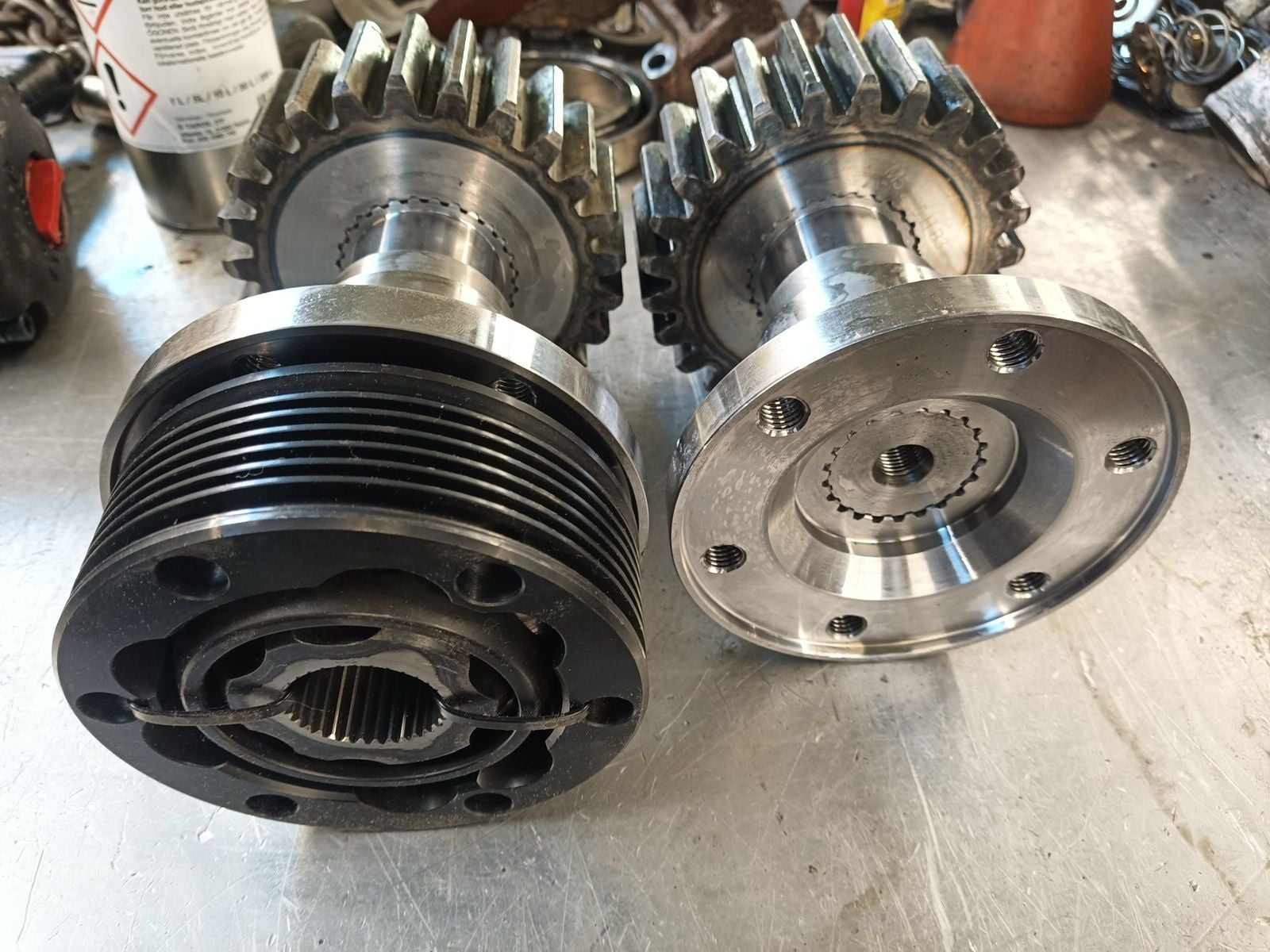

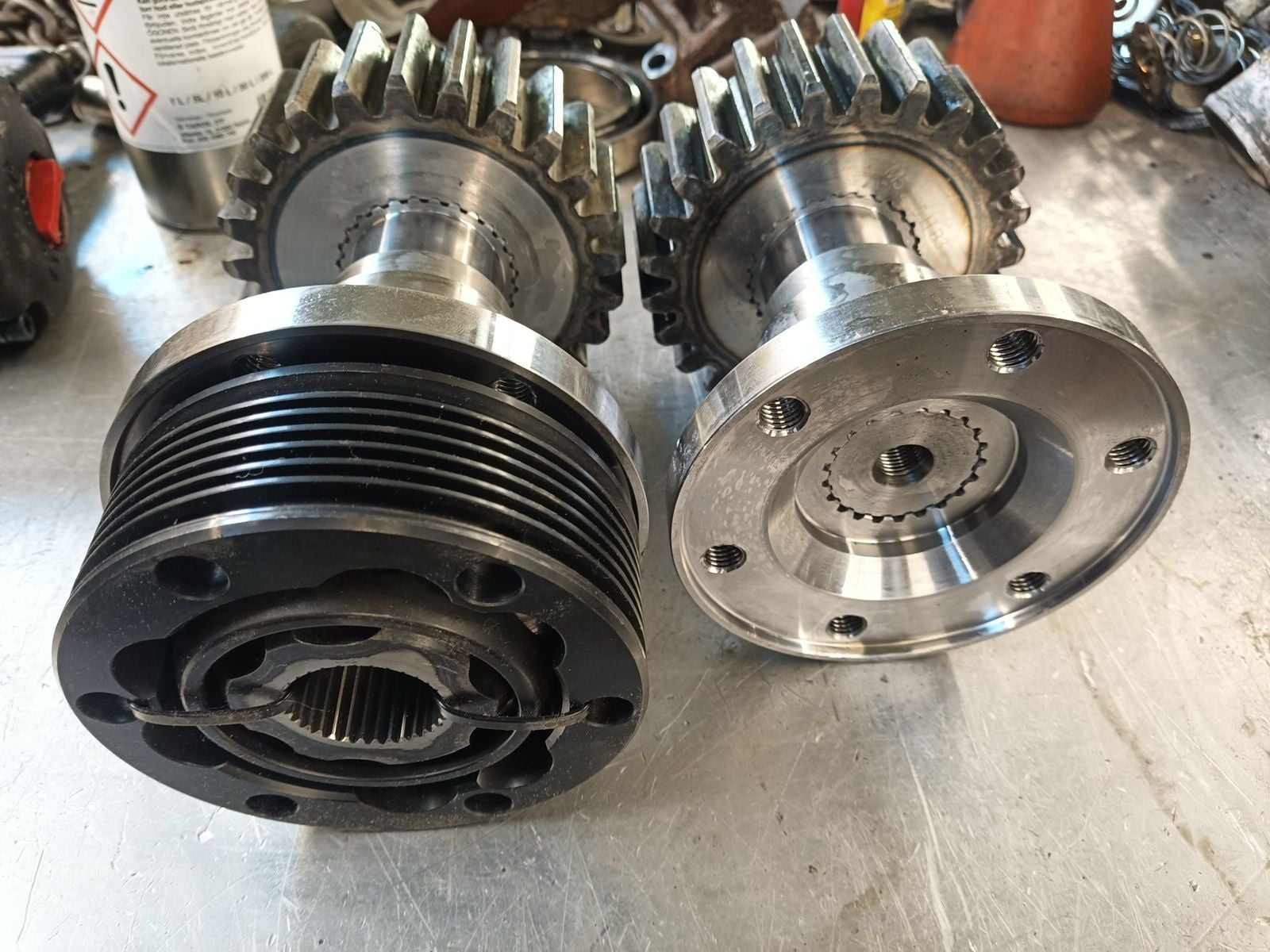

Spiltbox output shafts and flanges are ready, they are made of 42CrNiMo4 steel and have nitrided for surface hardness. Center spur gear is C45 steel and is nitrided also, other gears are induction hardened. Like I mentioned earlier, gears are not best material, but very cost efective to make this kind homemade special splitbox. If everything works but gears get wear, I will make better ones then.

I have been so busy at work and fix my current family boat Mariah Z276 so there have been no time for Fountain. My last purchase, carbon fiber Jetsurf, get all free time that I have. It's very fun sport, 90cc 2 stroke 10hp jet pump drive surfboard! In Finland was very warm early summer which cannot be ignored so little break of building Fountain give good motivation and brain rest.

Extension boxes are ready and painted, waiting for assembly.

Spiltbox output shafts and flanges are ready, they are made of 42CrNiMo4 steel and have nitrided for surface hardness. Center spur gear is C45 steel and is nitrided also, other gears are induction hardened. Like I mentioned earlier, gears are not best material, but very cost efective to make this kind homemade special splitbox. If everything works but gears get wear, I will make better ones then.

I have been so busy at work and fix my current family boat Mariah Z276 so there have been no time for Fountain. My last purchase, carbon fiber Jetsurf, get all free time that I have. It's very fun sport, 90cc 2 stroke 10hp jet pump drive surfboard! In Finland was very warm early summer which cannot be ignored so little break of building Fountain give good motivation and brain rest.

Last edited by ksalmine; 06-05-2024 at 01:05 PM.

The following 7 users liked this post by ksalmine:

AllDodge (06-05-2024), IGetWet (06-05-2024), offshorexcursion (06-06-2024), Quinlan (06-06-2024), rak rua (06-05-2024), Shah Mat (06-05-2024), Twin O/B Sonic (06-09-2024)