Fountain 47, 2372cid single engine diesel

The following users liked this post:

Samer (09-15-2023)

#82

Registered

Thread Starter

It looks nice! Keep working on it, hope you break 100kn some day...

#84

Registered

Thread Starter

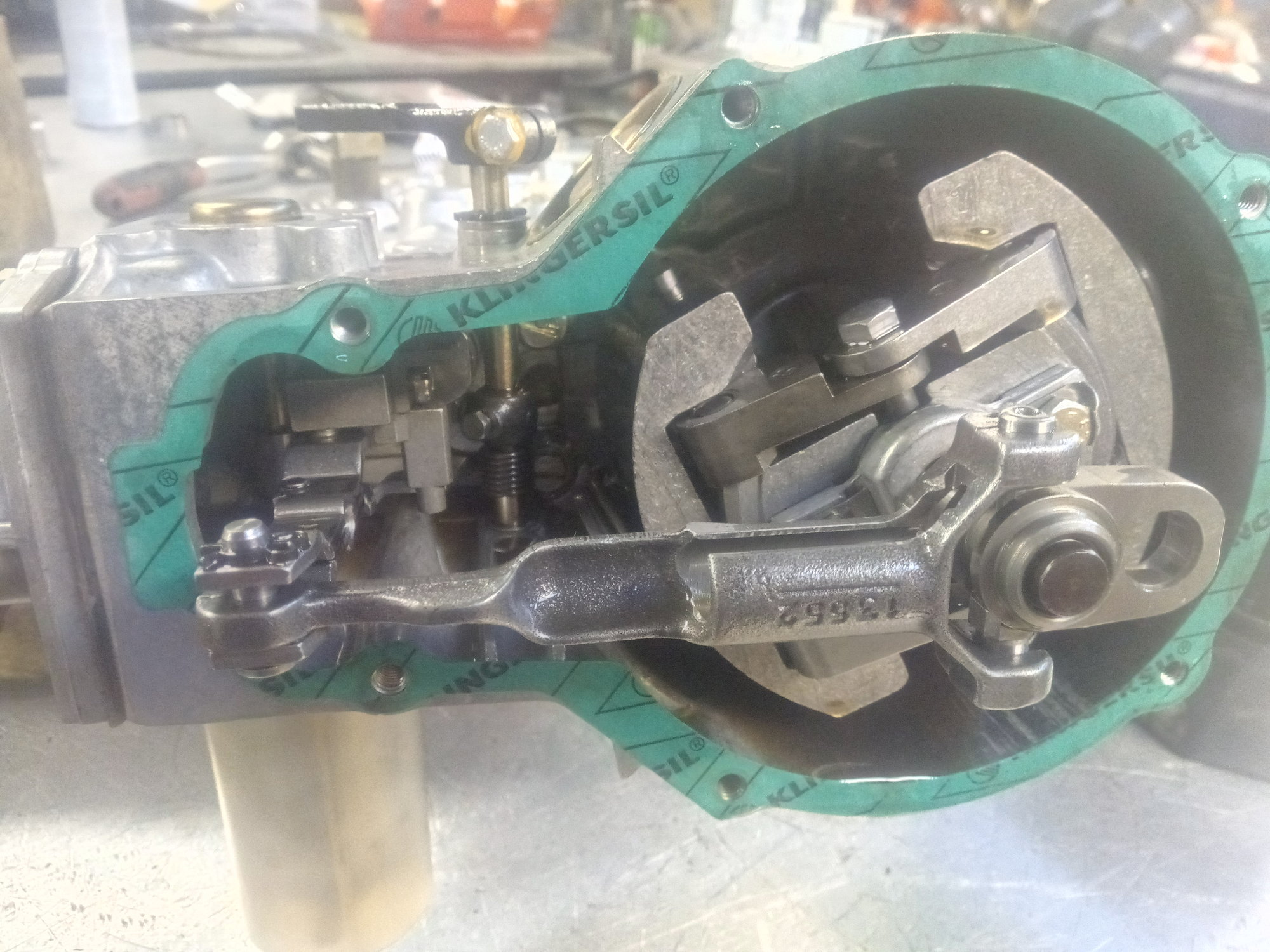

I knocked injection pump governor housing to engine block when trying match pump to engine. Result was tiny crack in housing. Disassembly governor, weld it with success and assembled again. It's very very complicated mechanical contoller.... hope so that I put it together correctly, if control rack get stuck, engine revs to explosion. Emergensy shut down system is must, some remote launch air intake shut off valve will do the work.

Pump has now good solid attachment to cylinder block and there are almoust no misalignement, spline coupling allow little misalignment but straighter the better.

Strarter pneumatics is also in their place, one way valves was quite dirty, if they leak combustion pressure and soot to starter, it can clog. Russians have done nice handicraft to pneumatic lines and banjo fittings.

Dry sump tank bracket is also done, I make many brackets and other not so important things first just mock up samples from iron, after first lake trial I disassemble whole thing, will make better parts from stainless and aluminium, paint everything and so on. Now it's useless make final parts because I'm sure that all parts won't be designed instantly right.

You can find unfinished heat exhancer from pic. I load more pics later when it's ready.

Next thing to do is design lubrication, cooling and hydraulic circuits... Needs lot of thinking and beers!

Pump has now good solid attachment to cylinder block and there are almoust no misalignement, spline coupling allow little misalignment but straighter the better.

Strarter pneumatics is also in their place, one way valves was quite dirty, if they leak combustion pressure and soot to starter, it can clog. Russians have done nice handicraft to pneumatic lines and banjo fittings.

Dry sump tank bracket is also done, I make many brackets and other not so important things first just mock up samples from iron, after first lake trial I disassemble whole thing, will make better parts from stainless and aluminium, paint everything and so on. Now it's useless make final parts because I'm sure that all parts won't be designed instantly right.

You can find unfinished heat exhancer from pic. I load more pics later when it's ready.

Next thing to do is design lubrication, cooling and hydraulic circuits... Needs lot of thinking and beers!

The following 7 users liked this post by ksalmine:

92nsx (10-08-2020), bulletbob (10-08-2020), Gimme Fuel (10-09-2020), kidturbo (10-07-2020), LakeHuronPower (10-15-2020), smashm (10-12-2020), SUPERSTITIOUS (10-07-2020)

#85

Registered

Thread Starter

Injectors are now ready. Special nozzles make very good and fine spray pattern, they should not make any idle haze. Injector size are now matched to 13mm pump plungers and 680cc delivery, I think they are good to 3000hp. Bosch nozzle horders are absolutely not plug and play item to transmash... They need tip sleeve, body sleeve, special holder and special injection pipe fittings, lot of lathe time.

Injection timing is another problem. I will try 20 degree BTDC first and put realtime cylinder pressure sensor to one starter passange and HALL trigger to crankshaft, then cylinder peak pressure timing can be measured with oscilloscope. I want peak pressure between 12-15 degree ATDC. It's very important to measure right timing, early timing kill engine without any warnings like detonation knock in gas engines, late timing doesn't give power and egt will be high.

Injector vertical location is also important that spray remains in piston bowl all injection event. I start stock height, if it need earlier timing, nozzle must drop lower, closer to piston dome.

Few other parts are almoust ready, more at next time, stay tuned.

The following 2 users liked this post by ksalmine:

Gimme Fuel (11-10-2020), SB (11-06-2020)

#88

Registered

Thread Starter

It's called Sleadehunden. I think they little overfuel it.... Greta will love that machine!

The following 3 users liked this post by ksalmine:

#89

Registered

Thread Starter

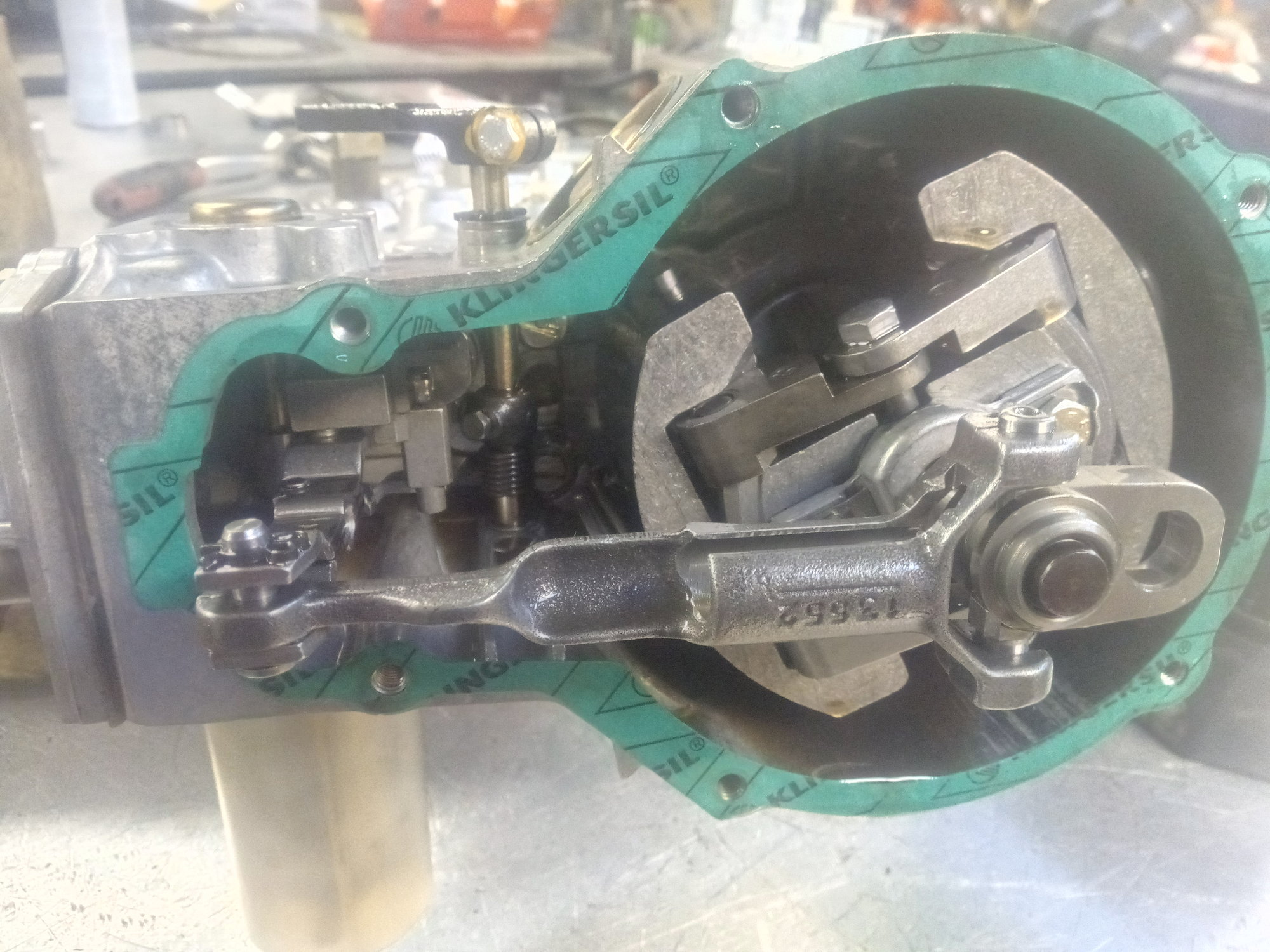

Center of nice CAD drawing is pump, sides are right and left cylinder banks.

Engine need new injection lines because different pump and pump firing order. It wasn't easy to find out which plunger feeds right cylinder at right time. Looks like Russians have made same firing order to master rod cylinder bank than cummins, pump came from vta 1710 maybe. Slave rod side is another story, there is absolute different firing order than cummins.... It's very difficult to make great looking line set when each line cross every other line.

Lenght of each pipe must be the same so they need go extra loops anyway.

Billet custom camshaft will solve the problem, perhaps some day. If I need more power, new cam with more lift will make pump produce 900cc/stroke fuel, it's worth of 3500hp

The following users liked this post:

mikebrls (11-14-2020)

#90

Registered

Thread Starter

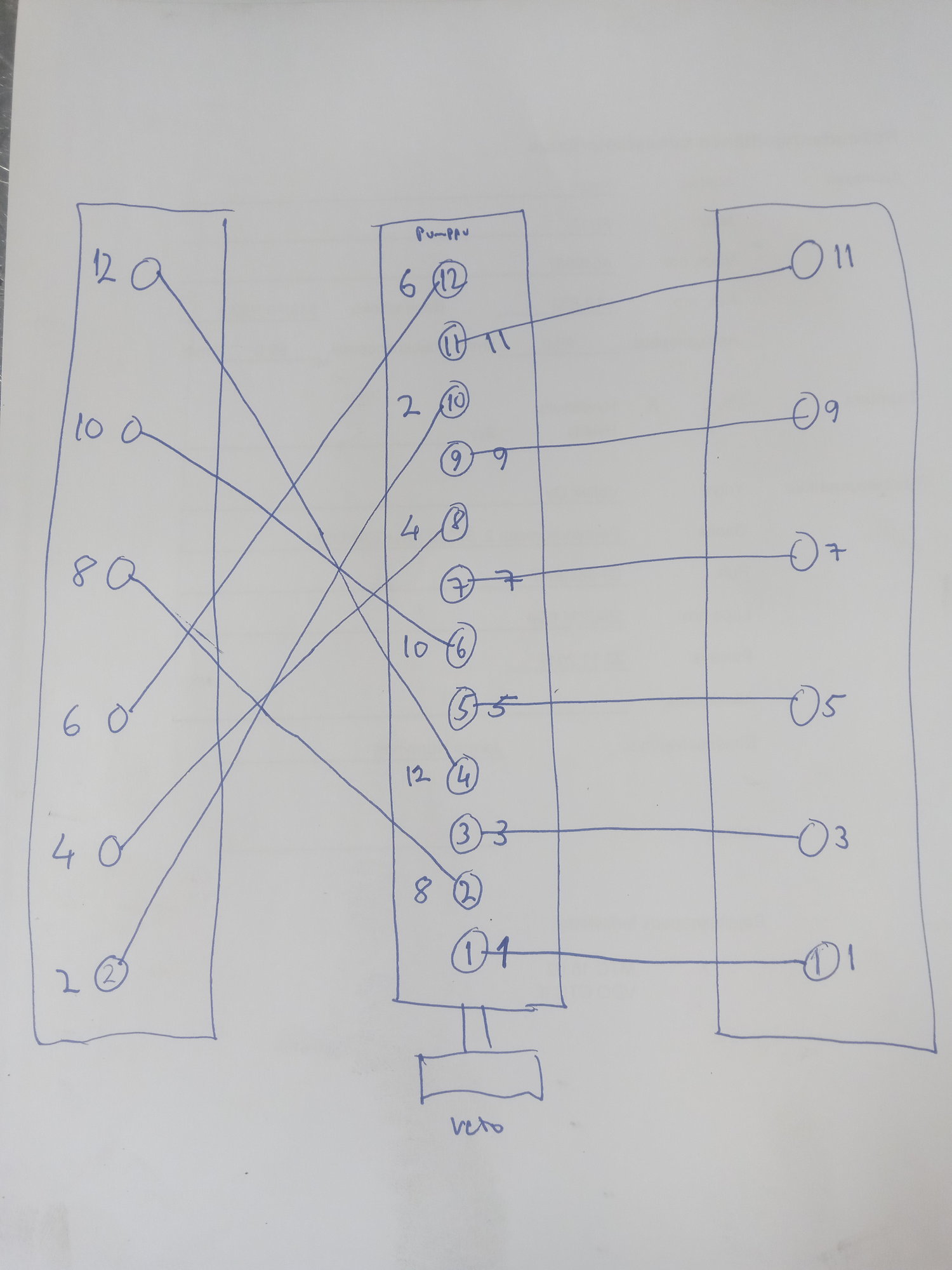

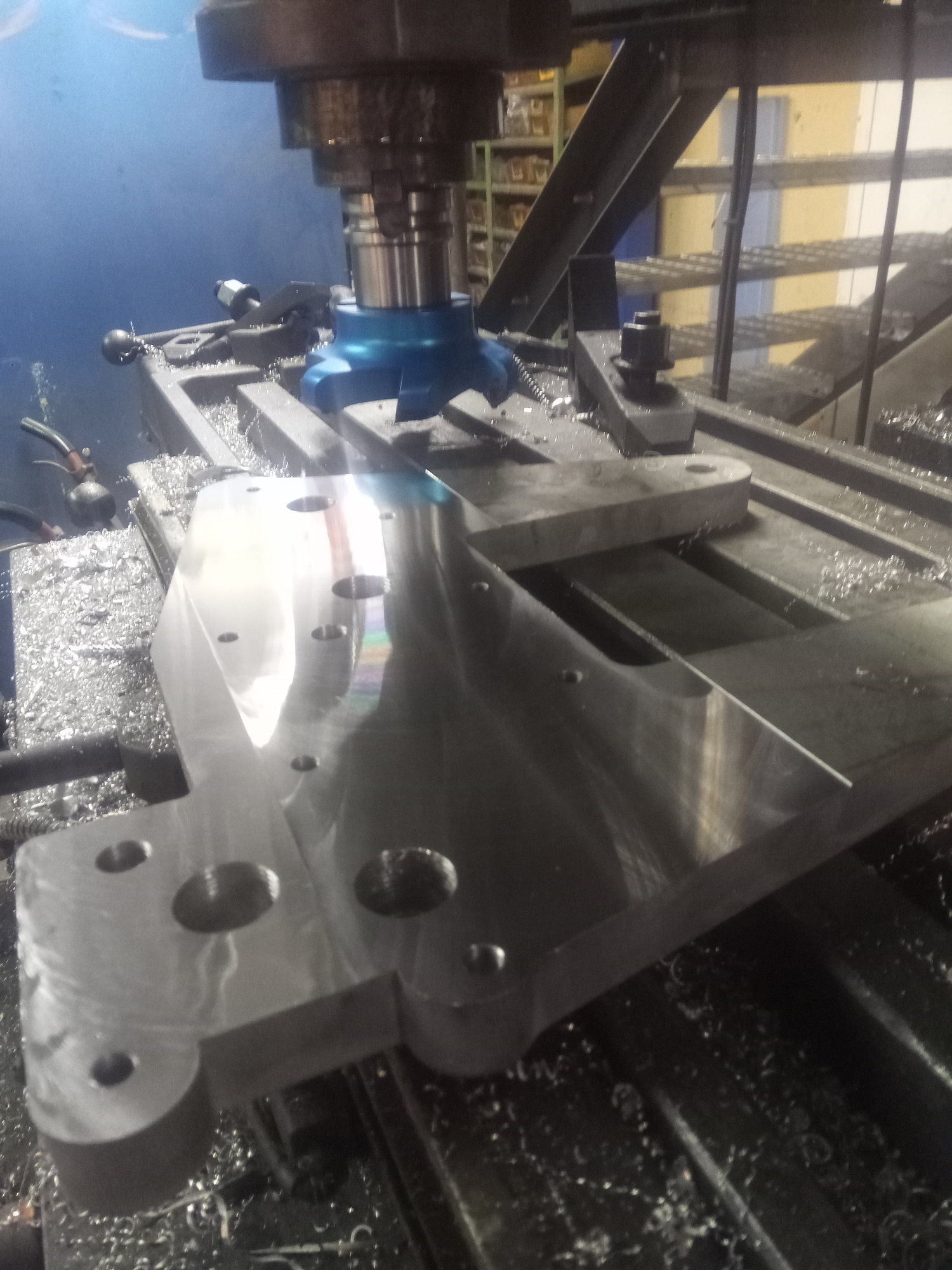

Oil system is getting together. Stock volvo D11 oil filter housing is bolted straight to engine block. I have to mill adapter plate for fittings and fastening.

pressure side are AN12, suction side AN16 and piston cooling oil AN8. It should be big enough. Engine oil pressure is 10bar.

There is now two big main flow filters and one much more fine side flow filter that feed turbos and injection pump.

Injector lines are hard to find. They must be 8mm od, 3mm id pipe so injection pressure in pump won't go too high. M14x1.5 double cone fittings is also hard to find, I have to contact some pulling store, they make custom lines.

The following users liked this post:

Gimme Fuel (12-01-2020)